glenfiddich

TravelsWithBarley.com

Last June, in West Virginia on our way to the BMW rally, a young woman pulling out of a hospital parking lot looked right at us, laughed as she pointed my dog out to her passenger, then looked the other way, gunned it and hit us broadside. Nobody was hurt, though she burst into tears when Glenlivet refused to allow her to hug him. Damage to the sidecar was minimized as I saw her in time to swerve so we took a glancing blow: the fender was gouged and cracked, the fiberglass tub itself had a three inch crack, the tire was torn but held air, the rim was gouged, and the camber control went to the full down position every time we hit a moderate bump. The front of her Chevy was completely torn off; her grill, license plate, bumper cover, passenger side headlight and turn signal were lying in the road.

When the police showed up my heart sank as she had grown up with him and they were on a first name basis. I hoped for professionalism and he was, in fact, very thorough and courteous, but the crash was listed as “no fault.”

I'm insured by Progressive and wasn’t sure what to expect. My only accident ever was in 1977 when an elderly woman in a huge Cadillac backed out of her driveway and hit my tiny Mazda while I was stopped at a controlled intersection.

But Progressive was fantastic from the start. I reported the crash immediately, but with duct tape and a new tire was able to ride home. A week later their adjuster came to my home to evaluate the damage. His first comment was “That’s some custom fiberglass work. And there’s no orange peel in the paint; someone spent some time on this rig!” He noted the point of impact and flat out rejected the police finding of no fault. (A few weeks later my deductible was refunded. Progressive had gone after the driver for the cost of repairs.)

The custom shop where the owner lets me work on my stuff was slammed, but winter is his slow time so if I could wait till the snow flew he’d let me do the work with his help as needed. Repairs started today. The lights, hardware, and electrical connections were unhooked, the tub removed and placed on a platform, the cracked fender and trim pieces removed, and all the adhesives taken off.

And now the work begins.

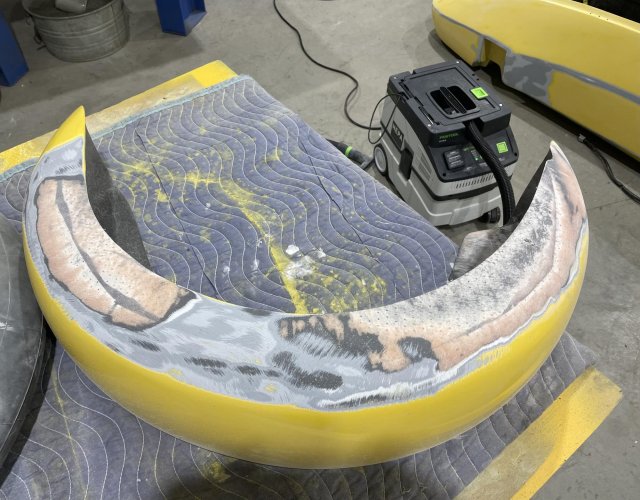

Side view showing fender damage

Closeup. The side of the tub has similar damage

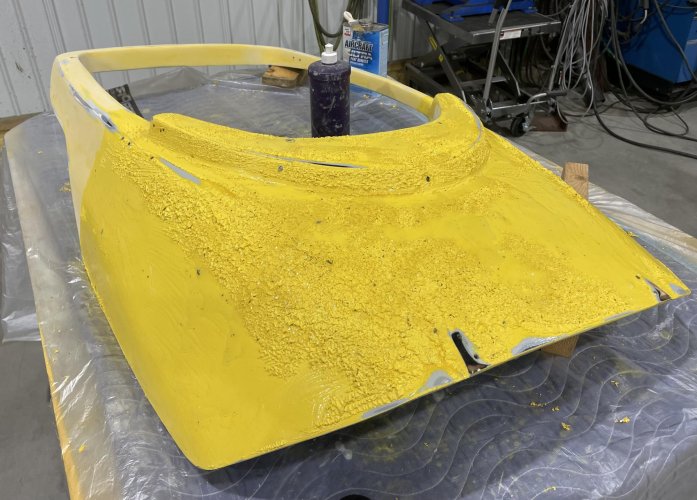

All the hardware needs to come off. Every hinge, twist lock and snap

On the gurney prepping for surgery

When the police showed up my heart sank as she had grown up with him and they were on a first name basis. I hoped for professionalism and he was, in fact, very thorough and courteous, but the crash was listed as “no fault.”

I'm insured by Progressive and wasn’t sure what to expect. My only accident ever was in 1977 when an elderly woman in a huge Cadillac backed out of her driveway and hit my tiny Mazda while I was stopped at a controlled intersection.

But Progressive was fantastic from the start. I reported the crash immediately, but with duct tape and a new tire was able to ride home. A week later their adjuster came to my home to evaluate the damage. His first comment was “That’s some custom fiberglass work. And there’s no orange peel in the paint; someone spent some time on this rig!” He noted the point of impact and flat out rejected the police finding of no fault. (A few weeks later my deductible was refunded. Progressive had gone after the driver for the cost of repairs.)

The custom shop where the owner lets me work on my stuff was slammed, but winter is his slow time so if I could wait till the snow flew he’d let me do the work with his help as needed. Repairs started today. The lights, hardware, and electrical connections were unhooked, the tub removed and placed on a platform, the cracked fender and trim pieces removed, and all the adhesives taken off.

And now the work begins.

Side view showing fender damage

Closeup. The side of the tub has similar damage

All the hardware needs to come off. Every hinge, twist lock and snap

On the gurney prepping for surgery