C172MyP51

New member

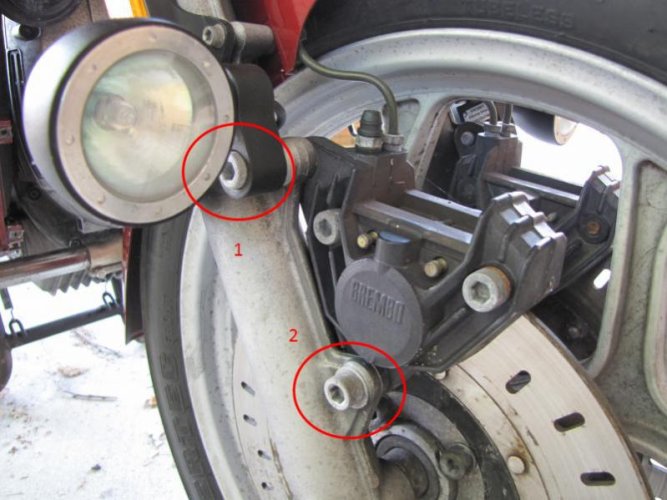

My newish-to-me R80 has a front wheel that only spins about a third of a turn when on the center stand. I just assumed it was the front brake grabbing, but after taking it on a 20 minute ride today, I noticed that every part of the brake system was cool to the touch!

I hate to ask, but, what does this mean, and how much is it gonna cost me? hahaha

I hate to ask, but, what does this mean, and how much is it gonna cost me? hahaha