scootrp125x

They call me Gort

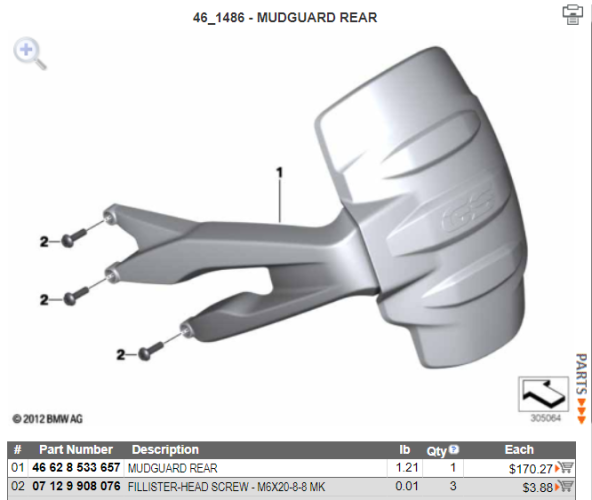

My new to me 2013 R1200GSW seems to have two of three screw hole threads stripped that hold the rear mudguard to the final drive. I have been doing maintenance that the previous owner should have done, new tires, brake pads, brake fluid replacement etc. I had to remove the rear mud guard several times. The front screw was missing so I ordered another one from the BMW dealer. I screwed it in and could tell that the threads were stripped. It seems that the middle screw threads are in about the same condition.

Anyone else have this problem and have a good solution? Can the holes be tapped, if so what tap size would I buy? Next size up maybe and a bigger diameter screw? What size would that be? I would like to use the original screws. Would a heli-coil work? I have never installed one but it should be possible although the hole does not seem very deep.

Do I really need the mudguard anyway? Is it only necessary for muddy off road riding? I'm a purely street rider and won't be going off road.

Thanks, Mark

Anyone else have this problem and have a good solution? Can the holes be tapped, if so what tap size would I buy? Next size up maybe and a bigger diameter screw? What size would that be? I would like to use the original screws. Would a heli-coil work? I have never installed one but it should be possible although the hole does not seem very deep.

Do I really need the mudguard anyway? Is it only necessary for muddy off road riding? I'm a purely street rider and won't be going off road.

Thanks, Mark