88bmwjeff

SF Bay Area

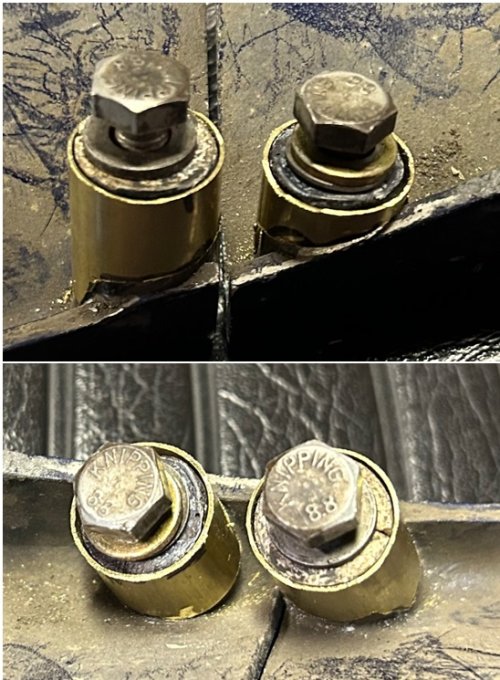

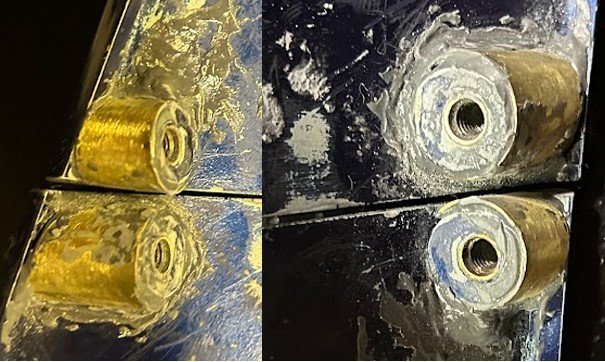

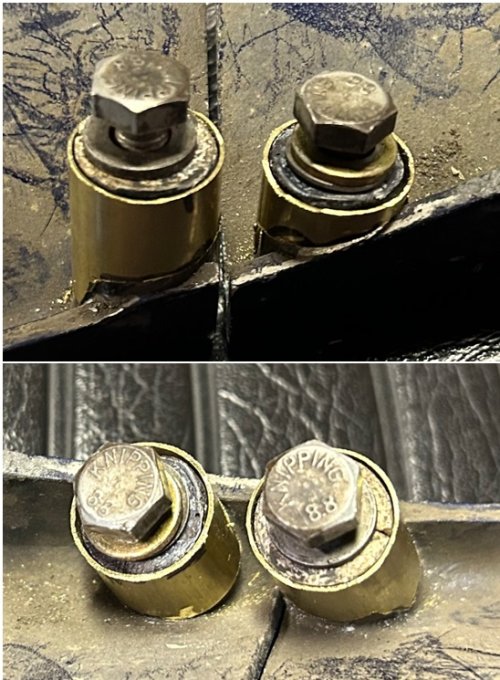

Those of us who have RT's or RS's with the lower fairing's typically have issues with cracking (and breaking of the fairing) around the embedded nuts at the bottom of the fairing underneath the cylinders. I've got some cracking, but none have broken yet. I've been thinking about a good solution to strengthen the areas with the embedded nuts. My thought is to create sleaves to go over the fairing portion with the embedded nuts. These sleaves would be epoxied in place. I've worked through the right side, but I still have the left side sleaves to make before epoxying in place.

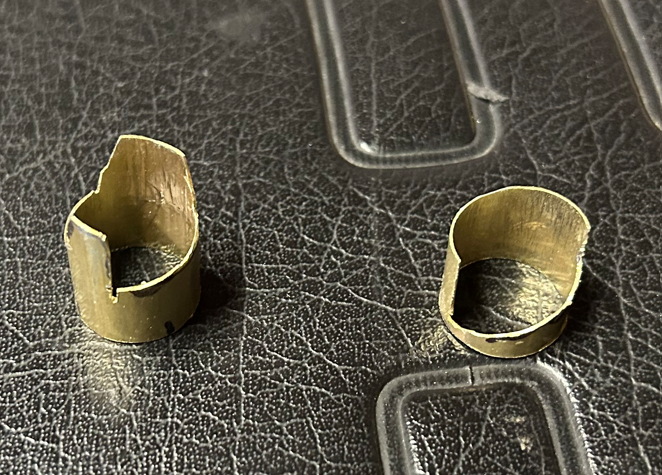

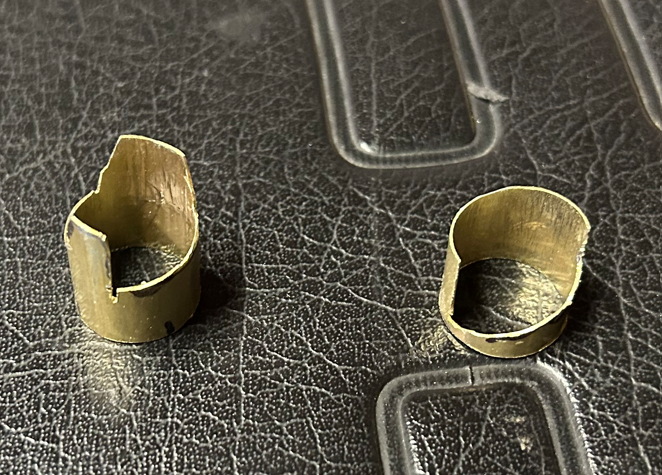

I went to the local hardware store and purchased some brass metal tubing, then cut them to fit as best as possible. As you can see from the photo of them removed, they are quite odd in shape. In case anyone is curious, I used a Dremel with a cutting wheel to cut the tubbing. It's hard to tell from the photos, but the top of the sleaves are just below the top of the embedded nuts. Here are some photos of what's done so far.

I went to the local hardware store and purchased some brass metal tubing, then cut them to fit as best as possible. As you can see from the photo of them removed, they are quite odd in shape. In case anyone is curious, I used a Dremel with a cutting wheel to cut the tubbing. It's hard to tell from the photos, but the top of the sleaves are just below the top of the embedded nuts. Here are some photos of what's done so far.