Thanks to all of the questions and responses on the forum too numerous to mention. IÔÇÖm very weak at electrical testing, but after 8 hours, mostly reading posts and wiring diagrams, IÔÇÖve progressed further than anticipated.

I offer apologies in advance for my lack of technical terminology.

Hopefully I can get a little help to get me over this last part.

Symptom: Bike stalled while humming along at 60 mph on the Freeway, never to start again.

A two mile tow to my place of business left me thankful and my wallet $100 lighter.

What IÔÇÖve checked:

1) Spark: Good

2) In neutral, pressed start button, and listened at tank opening. No sound.

3) Backed this up with a fuel pressure test. Result: 0 pressure.

4) Checked fuses with ohm meter: All good.

5) Cleaned battery positive (to Injection Pump Relay & Starter Relay) cables and negative cables and established good clean connections. Ground connection to engine also good.

6) Drained tank, blew out air, and hot wired pump (direct current to pump in tank ÔÇÿyellow wireÔÇÖ and direct ground from pump ÔÇÿblack wireÔÇÖ). Works and sounds fine.

7) Tested for voltage at fuse with direct ground at Green/Red wire (#87) from Fuel Injection Relay: Result 11.8v This was the #6 fuse (6th fuse down from the top of the fuse stack on the left side). Pressed starter button and received 11.8v for about 2 seconds. To me it indicates that the relay is working.

8) Tested for voltage at the 4 wire connection at the back of the tank at the supply (female) side. This was the Green/White wire coming from the #6 fuse. Again, pressed the starter button and received 11.8v for two seconds. This also indicates that the fuse is good.

9) Jumped the 4-wire sending unit connection (supply side Green/White female wire connector) to the Green wire on the tank (output/male) side, with HARD WIRE GROUND (from black wire on fuel pump directly to ground). I wanted to see if power was getting to the fuel pump independent of the harness connection by using a good jump. The result (after pressing start button) is that the pump ran fine for 2 seconds.

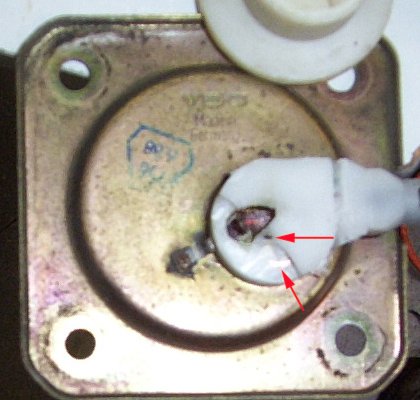

If I connect the sending unit plug and test the pump it does not work.

Here is where IÔÇÖm getting stuck. How do I verify that the ground is good on the sending unit? My understanding that the brown wire on the tank side connection (male) is the ground wire (not sure though). I also should check the ground source for the sending unit. Does anyone know where that is located? By this I mean to ask ÔÇ£Where does the sending unit get its ground from?ÔÇØ I suppose if I could jump the power as in item 9 above AND jump the brown (?) wire directly to gound that should verify that the sending unit is OK. Then the ground source would be the most likely culprit or the 4-wire connection itself. The problem with this test is the close proximity of the male connectors and avoiding a short.

The last couple of paragraphs sound confusing to me. Let me know if pictures will help and IÔÇÖll supply them.

My next plan is to get some electrical cleaner and clean out the 4-pin plug connection and try it again.

Thanks in advance for your help,

Pete

I offer apologies in advance for my lack of technical terminology.

Hopefully I can get a little help to get me over this last part.

Symptom: Bike stalled while humming along at 60 mph on the Freeway, never to start again.

A two mile tow to my place of business left me thankful and my wallet $100 lighter.

What IÔÇÖve checked:

1) Spark: Good

2) In neutral, pressed start button, and listened at tank opening. No sound.

3) Backed this up with a fuel pressure test. Result: 0 pressure.

4) Checked fuses with ohm meter: All good.

5) Cleaned battery positive (to Injection Pump Relay & Starter Relay) cables and negative cables and established good clean connections. Ground connection to engine also good.

6) Drained tank, blew out air, and hot wired pump (direct current to pump in tank ÔÇÿyellow wireÔÇÖ and direct ground from pump ÔÇÿblack wireÔÇÖ). Works and sounds fine.

7) Tested for voltage at fuse with direct ground at Green/Red wire (#87) from Fuel Injection Relay: Result 11.8v This was the #6 fuse (6th fuse down from the top of the fuse stack on the left side). Pressed starter button and received 11.8v for about 2 seconds. To me it indicates that the relay is working.

8) Tested for voltage at the 4 wire connection at the back of the tank at the supply (female) side. This was the Green/White wire coming from the #6 fuse. Again, pressed the starter button and received 11.8v for two seconds. This also indicates that the fuse is good.

9) Jumped the 4-wire sending unit connection (supply side Green/White female wire connector) to the Green wire on the tank (output/male) side, with HARD WIRE GROUND (from black wire on fuel pump directly to ground). I wanted to see if power was getting to the fuel pump independent of the harness connection by using a good jump. The result (after pressing start button) is that the pump ran fine for 2 seconds.

If I connect the sending unit plug and test the pump it does not work.

Here is where IÔÇÖm getting stuck. How do I verify that the ground is good on the sending unit? My understanding that the brown wire on the tank side connection (male) is the ground wire (not sure though). I also should check the ground source for the sending unit. Does anyone know where that is located? By this I mean to ask ÔÇ£Where does the sending unit get its ground from?ÔÇØ I suppose if I could jump the power as in item 9 above AND jump the brown (?) wire directly to gound that should verify that the sending unit is OK. Then the ground source would be the most likely culprit or the 4-wire connection itself. The problem with this test is the close proximity of the male connectors and avoiding a short.

The last couple of paragraphs sound confusing to me. Let me know if pictures will help and IÔÇÖll supply them.

My next plan is to get some electrical cleaner and clean out the 4-pin plug connection and try it again.

Thanks in advance for your help,

Pete