gtgt_bangbang

New member

PULLER PLATE

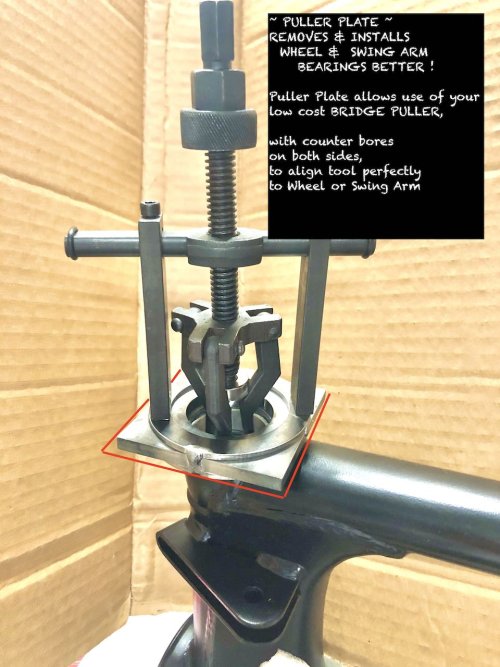

I made some custom PULLER PLATES to allow the use of a cheap BRIDGE PULLER to R&R wheel bearings and swing arm bearings.

Tool is basically a 1/4" mega-duty "washer" with a 41mm hole (just > bearing-size ) in it , with 2 additional "washer" plates welded to either side;

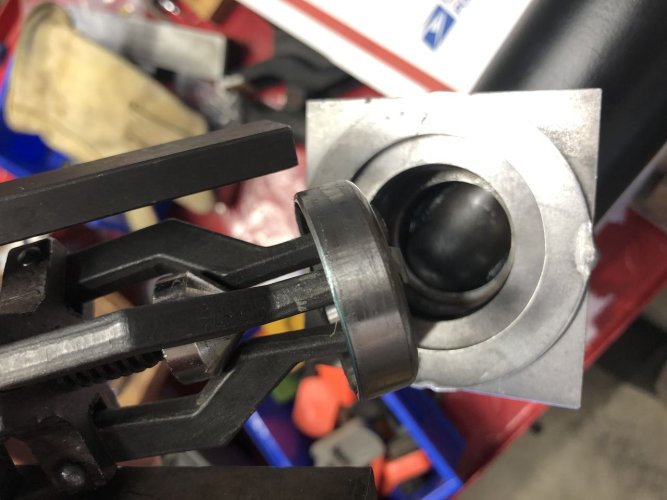

one face is designed to slip snug around the wheel's bearing 'post' to securely align the center hole over the wheel bearing.

The Puller Plate provides a bull-strong & rock-steady rest for the bridge-puller legs while protecting the wheel's aluminum edge when pulling bearing.

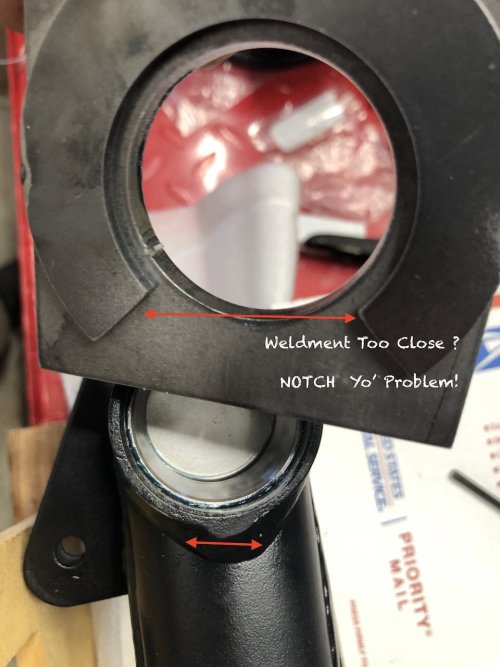

other face centers up tool on the (nearly non-existent!) swing-arm bearing tube, providing the surface to rest bridge-puller legs upon,

The swing arm 'washer' is notched to avoid weldments which are present on certain swing arms, which would otherwise block square sitting.

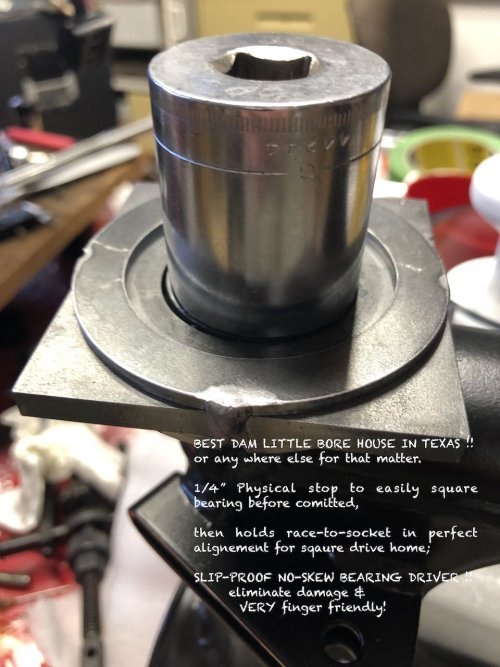

When its time to install the new bearings, the thick plate serves as an excellent visual reference & HARD PHYSICAL STOP to assure the bearing alignment is square & level before its too late. The bearing is still 1/4" proud of bore and can be easily leveled to Puller Plate surface before wailing it home.

A couple taps more and the center plate's bore holds the driver (a socket or drift) in precise alignment to the bearing race,

(use any socket near 40~41 OD, 30mm Craftsman 1/2" was OK here )

With the driver in perfect alignment to both workpiece and bearing/race, you can focus on hammering as this TOOL CANT SLIP, your drift wont get off center, protecting the bearing and your fingers!

I think I picked up that bridge-style puller on ebay for peanuts.

View attachment 88890View attachment 88891View attachment 88892View attachment 88893View attachment 88894View attachment 88895View attachment 88896View attachment 88897View attachment 88898

I made some custom PULLER PLATES to allow the use of a cheap BRIDGE PULLER to R&R wheel bearings and swing arm bearings.

Tool is basically a 1/4" mega-duty "washer" with a 41mm hole (just > bearing-size ) in it , with 2 additional "washer" plates welded to either side;

one face is designed to slip snug around the wheel's bearing 'post' to securely align the center hole over the wheel bearing.

The Puller Plate provides a bull-strong & rock-steady rest for the bridge-puller legs while protecting the wheel's aluminum edge when pulling bearing.

other face centers up tool on the (nearly non-existent!) swing-arm bearing tube, providing the surface to rest bridge-puller legs upon,

The swing arm 'washer' is notched to avoid weldments which are present on certain swing arms, which would otherwise block square sitting.

When its time to install the new bearings, the thick plate serves as an excellent visual reference & HARD PHYSICAL STOP to assure the bearing alignment is square & level before its too late. The bearing is still 1/4" proud of bore and can be easily leveled to Puller Plate surface before wailing it home.

A couple taps more and the center plate's bore holds the driver (a socket or drift) in precise alignment to the bearing race,

(use any socket near 40~41 OD, 30mm Craftsman 1/2" was OK here )

With the driver in perfect alignment to both workpiece and bearing/race, you can focus on hammering as this TOOL CANT SLIP, your drift wont get off center, protecting the bearing and your fingers!

I think I picked up that bridge-style puller on ebay for peanuts.

View attachment 88890View attachment 88891View attachment 88892View attachment 88893View attachment 88894View attachment 88895View attachment 88896View attachment 88897View attachment 88898

Attachments

-

NEW PULLER PLATE - 1.jpeg126.1 KB · Views: 53

NEW PULLER PLATE - 1.jpeg126.1 KB · Views: 53 -

NEW PULLER PLATE - 2.jpeg150.3 KB · Views: 52

NEW PULLER PLATE - 2.jpeg150.3 KB · Views: 52 -

NEW PULLER PLATE - 3.jpeg108 KB · Views: 54

NEW PULLER PLATE - 3.jpeg108 KB · Views: 54 -

NEW PULLER PLATE - 4.jpeg101.1 KB · Views: 52

NEW PULLER PLATE - 4.jpeg101.1 KB · Views: 52 -

NEW PULLER PLATE - 5.jpeg104.1 KB · Views: 54

NEW PULLER PLATE - 5.jpeg104.1 KB · Views: 54 -

NEW PULLER PLATE - 6.jpeg115 KB · Views: 52

NEW PULLER PLATE - 6.jpeg115 KB · Views: 52 -

NEW PULLER PLATE - 7.jpeg151.5 KB · Views: 53

NEW PULLER PLATE - 7.jpeg151.5 KB · Views: 53 -

NEW PULLER PLATE - 8.jpeg146.4 KB · Views: 53

NEW PULLER PLATE - 8.jpeg146.4 KB · Views: 53

Last edited: