evillerich

New member

Hello,

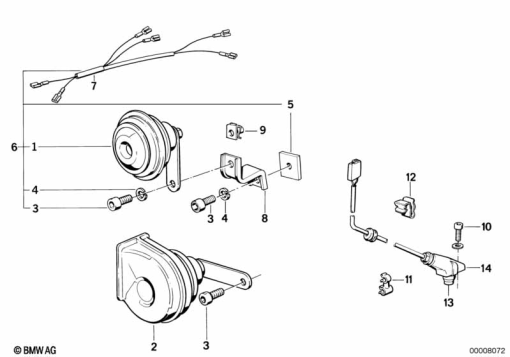

I'm continuing on my 1987 K75S endless rebuild project. After appearing to resolve the shaky fairing issue (it's nice and tight now), I'm turning my attention to the horn. I'm 93.2% sure this bike had a tip-over at some point due to the fairing condition and am not convinced the horn was ever mounted properly. The PO had it mounted under the headlight, using the bolt that ties the two fairing sides to the headlight frame. Seemed to have a lot of movement and I don't really like the weight of the horn bouncing around on that point. The problem solved itself with the metal bracket that tied the horn to the fairing bolt location failing due to metal fatigue, leaving the horn dangling.

In my research, I see mention of the plastic headlight frame being used to hold the horn, however, I can see no sign of any connecting parts that would have tied-in there. And parts seem scarce, if even available. I'm at a bit of a loss as to exactly how the horn is supposed to be mounted. I'm ready to find my own solution.

On the triple tree, I do see two unused bolt holes (one on each side). I'm considering some sort of bracket that would use these bolt holes and provide a central mounting point for the horn.

Wondering if there are any known clever solutions out there. I'm willing to try an aftermarket horn kit if it comes with a mounting solution.

Thank you!

Eville Rich

1987 K75S

I'm continuing on my 1987 K75S endless rebuild project. After appearing to resolve the shaky fairing issue (it's nice and tight now), I'm turning my attention to the horn. I'm 93.2% sure this bike had a tip-over at some point due to the fairing condition and am not convinced the horn was ever mounted properly. The PO had it mounted under the headlight, using the bolt that ties the two fairing sides to the headlight frame. Seemed to have a lot of movement and I don't really like the weight of the horn bouncing around on that point. The problem solved itself with the metal bracket that tied the horn to the fairing bolt location failing due to metal fatigue, leaving the horn dangling.

In my research, I see mention of the plastic headlight frame being used to hold the horn, however, I can see no sign of any connecting parts that would have tied-in there. And parts seem scarce, if even available. I'm at a bit of a loss as to exactly how the horn is supposed to be mounted. I'm ready to find my own solution.

On the triple tree, I do see two unused bolt holes (one on each side). I'm considering some sort of bracket that would use these bolt holes and provide a central mounting point for the horn.

Wondering if there are any known clever solutions out there. I'm willing to try an aftermarket horn kit if it comes with a mounting solution.

Thank you!

Eville Rich

1987 K75S