henrymccann

New member

I bought a 1994 BMW K75S two years ago with 25,250 miles, excellent condition and was running well. Tires almost new. Always stored indoors.

I moved shortly thereafter and it was put in storage, stupidly with gas in the tank. I now have it out of storage and want to get it on the road. A dead battery of course, but before I tried to start it what steps should I take first? Drain and replace gas? Replace what parts? Other?

I've done basic maintenance on a VStrom 650 and a Honda ST1300 but would never pretend to call myself a mechanic. I'm willing to learn and have a brother-in-law with lots of wrenching experience on dirt bikes and street bikes from Honda, Yamaha, Kawasaki, Suzuki and Harley), but never BMW. He lives 3 hours away but FaceTime works.

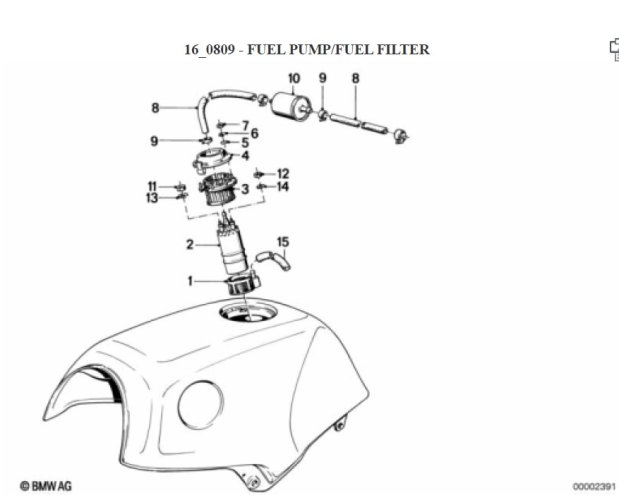

I've already read posts on the importance of splines checked and lubed and possibly a rubber gasket dissolved into the gas after sitting? My wife wants to ride with me so I'm guessing better suspension is needed.

Since I'm new to the site, I'm happy to read any pertinent old posts I haven't found yet and don't expect the experts here to reinvent/explain the wheel/common information for a newbie.

First BMW and excited to learn and ride this bike, Thank you in advance!

I moved shortly thereafter and it was put in storage, stupidly with gas in the tank. I now have it out of storage and want to get it on the road. A dead battery of course, but before I tried to start it what steps should I take first? Drain and replace gas? Replace what parts? Other?

I've done basic maintenance on a VStrom 650 and a Honda ST1300 but would never pretend to call myself a mechanic. I'm willing to learn and have a brother-in-law with lots of wrenching experience on dirt bikes and street bikes from Honda, Yamaha, Kawasaki, Suzuki and Harley), but never BMW. He lives 3 hours away but FaceTime works.

I've already read posts on the importance of splines checked and lubed and possibly a rubber gasket dissolved into the gas after sitting? My wife wants to ride with me so I'm guessing better suspension is needed.

Since I'm new to the site, I'm happy to read any pertinent old posts I haven't found yet and don't expect the experts here to reinvent/explain the wheel/common information for a newbie.

First BMW and excited to learn and ride this bike, Thank you in advance!