L

lonelobo

Guest

Somewhere it's Miller Time

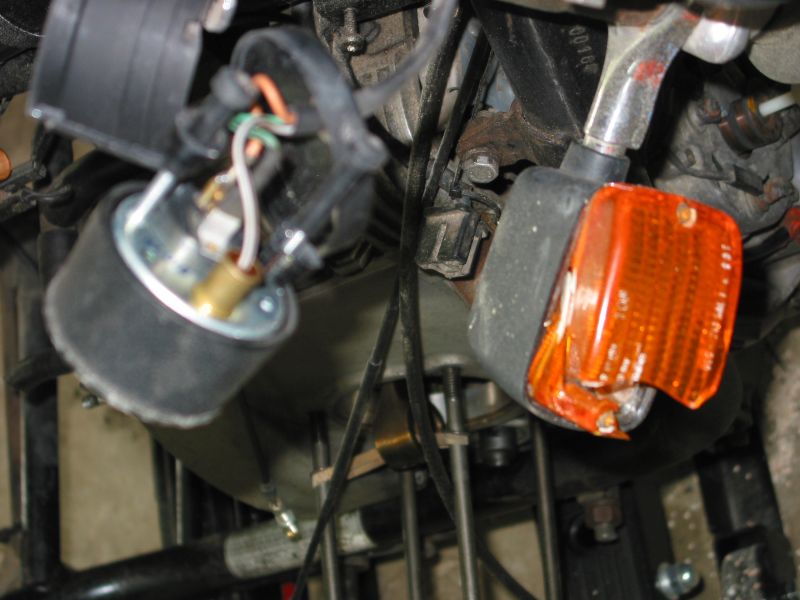

Didn't take any pix of dropping the driveshaft. I had all the transmission bolts out and she would slide back a bit, but the clutch lever on the back kept hitting the frame and wouldn't allow me to slide it back far enough for removal. I avoided pulling the lever off because according to one of the on line fiche's it should have a threaded end and a nut that kept it from coming off. There was NO nut. I finally went to another online fiche and found there was another variation that has a E-clip. But look as I might I couldn't find a clip. Then, Hillbilly Mechanic rule #2 popped into my head. Iffin it otta come out, hit it with sumpin. I used what was in my hand at the time...a screwdriver and the pin popped out. The e clip was indeed missing and nowhere to be found. Imagifukin that?!

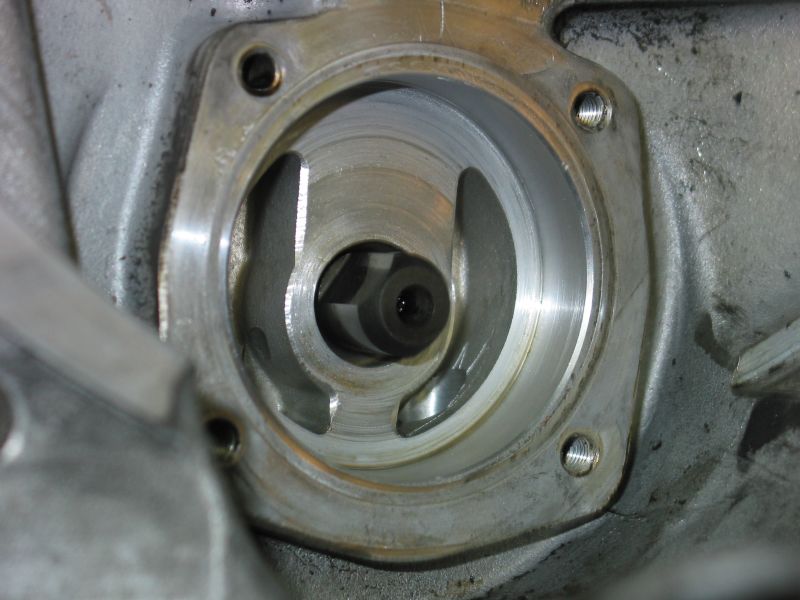

Even better is when the needle bearing came out with exactly 1 needle still intact.

I want to take a moment to point out to those of you who have advised me to part this bike out that I have yet to come upon a part that could be sold without several national and state consumer protection laws being broken.

Now, just when you're thinkin to yourself that things can't get much worse.....

and I can hardly bear to say this because it verifies my:

1) impatience

2) stupidity

3) belief that faith can trump physics

First, we have to take a couple of steps back. For some stupid unknown reason, I never put the oil pan back on after finding all the nasty con rod bits. I think that my subconscious mind was absolutely positive that transmission fairies can't travel down through the engine to miraculously fix it, they must in fact, have the pan left off so they can do their magic while on their backs as we sleep.

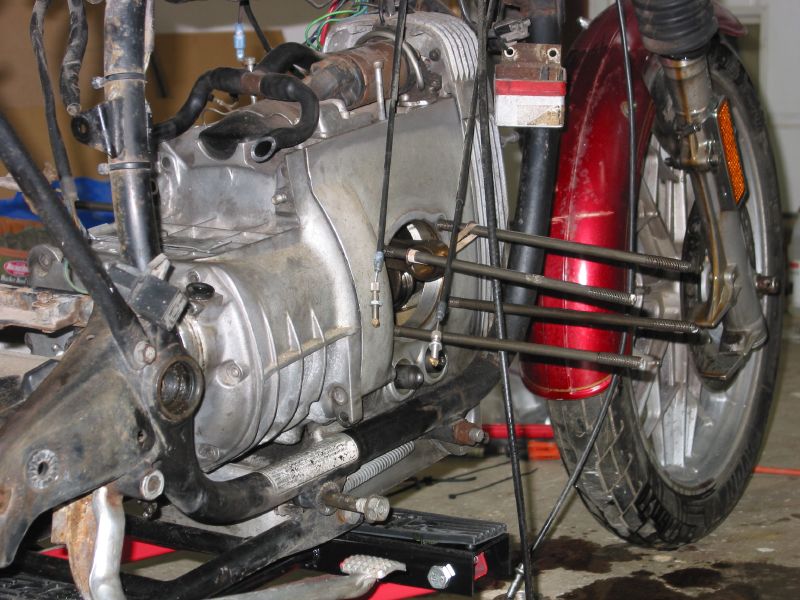

Anyhow, I also meant to fabricate something to make the lift work better with the bike but never got around to it. I had to put a couple of pieces of wood on each leg of the lift to avoid hitting the oil sump. Then, when I pulled the wheel and dropped the drive shaft, physics happened.

The bike pulled forward just enough to start bending the oil sump cover. So thinking really fast, I got a bottle jack and a piece of 1X4 and got the rear end lifted enough to get the pressure off the oil screen. Now, I just needed to stabilize it while I figured out how to get the oil pan back on so the big lift could do it's job unhindered.

Hey looky here, there's a big ole sturdy 5 gal bucket that I can rest the rear swingarm tabs on just for a minute while I get the oil pan on while the big lift is lowered....

so who of you can project now about 45 seconds into this Patton like plan to conquer the oil pan and predict what happened next?

I swear, I thought 5 gallon sheetrock texture buckets were much stronger.

Didn't take any pix of dropping the driveshaft. I had all the transmission bolts out and she would slide back a bit, but the clutch lever on the back kept hitting the frame and wouldn't allow me to slide it back far enough for removal. I avoided pulling the lever off because according to one of the on line fiche's it should have a threaded end and a nut that kept it from coming off. There was NO nut. I finally went to another online fiche and found there was another variation that has a E-clip. But look as I might I couldn't find a clip. Then, Hillbilly Mechanic rule #2 popped into my head. Iffin it otta come out, hit it with sumpin. I used what was in my hand at the time...a screwdriver and the pin popped out. The e clip was indeed missing and nowhere to be found. Imagifukin that?!

Even better is when the needle bearing came out with exactly 1 needle still intact.

I want to take a moment to point out to those of you who have advised me to part this bike out that I have yet to come upon a part that could be sold without several national and state consumer protection laws being broken.

Now, just when you're thinkin to yourself that things can't get much worse.....

and I can hardly bear to say this because it verifies my:

1) impatience

2) stupidity

3) belief that faith can trump physics

First, we have to take a couple of steps back. For some stupid unknown reason, I never put the oil pan back on after finding all the nasty con rod bits. I think that my subconscious mind was absolutely positive that transmission fairies can't travel down through the engine to miraculously fix it, they must in fact, have the pan left off so they can do their magic while on their backs as we sleep.

Anyhow, I also meant to fabricate something to make the lift work better with the bike but never got around to it. I had to put a couple of pieces of wood on each leg of the lift to avoid hitting the oil sump. Then, when I pulled the wheel and dropped the drive shaft, physics happened.

The bike pulled forward just enough to start bending the oil sump cover. So thinking really fast, I got a bottle jack and a piece of 1X4 and got the rear end lifted enough to get the pressure off the oil screen. Now, I just needed to stabilize it while I figured out how to get the oil pan back on so the big lift could do it's job unhindered.

Hey looky here, there's a big ole sturdy 5 gal bucket that I can rest the rear swingarm tabs on just for a minute while I get the oil pan on while the big lift is lowered....

so who of you can project now about 45 seconds into this Patton like plan to conquer the oil pan and predict what happened next?

I swear, I thought 5 gallon sheetrock texture buckets were much stronger.