gsaddict

Pepperfool

Well, I'm happy to report that when I pulled off the valve covers, I didn't have a naked sprocket staring back at me. But I did expect to find some irregularities with the valve clearances. Strangely enough, they were in the ballpark.

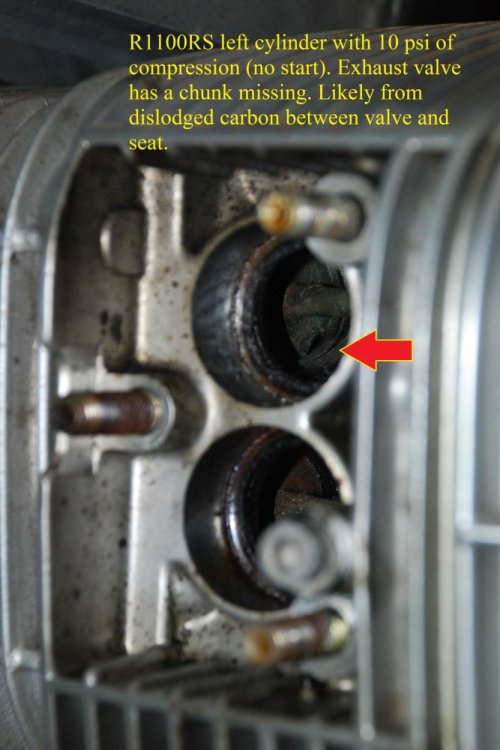

Perhaps I've got a chunk of valve missing (as was suggested earlier) and that's the reason it's not sealing...

I had this happen a few years ago. Hard pass and heavy pinging. Suspect a chunk of carbon got stuck under the valve seat for a few revs.

That's all it takes.

The engine was an oil consumer (softly broken in by the owner before me) I re-ringed the engine at the time of the head rebuild and broke it in hard.

Consequently it now consumes very little oil and has no real carbon to speak of with a borescope inspection.

The rebuild was 85,000 miles ago

Attachments

Last edited:

...I couldn't get it too idle long enough to do much once home. Nothing to leakdown on that side

...I couldn't get it too idle long enough to do much once home. Nothing to leakdown on that side full blown opening for sure...at least not a holed piston!

full blown opening for sure...at least not a holed piston!

which was posted on the GS Giants Facebook page. Seeing this, it's no wonder we have carbon bits wedging in valve seats and chipping valves. My question is: What is the leading cause of carbon build-up, and can anything be done to prevent it?

which was posted on the GS Giants Facebook page. Seeing this, it's no wonder we have carbon bits wedging in valve seats and chipping valves. My question is: What is the leading cause of carbon build-up, and can anything be done to prevent it?