crazydrummerdude

advrider.com

Dude!

Email me. I think I have the part for you.

PM'ed you on advrider.

You can get the manual impact drivers that are quite inexpensive at most harware stores.

I have one, but there's no way I can get a swing at it in that small area. I can just barely tap it.

Last time, I had a neighbor that I borrowed a small 90 degree electric impact from, and after blasting through some non-hardened bits, I got them out.

Nathan,

I hope you blocked the crank on the other end of the motor before removing the flywheel.

Yep, I used crazydrummerdude's patented broken 2x4" chunk taped to the rotor..

..with the front cover replaced, of course.

I also endores the manual impact driver as an essential tool. The heft of the thing is just perfect for nudging stubborn screws on a CV carb top.

Exactly!

What ever turned out with your broken starter from the R90?

I was waiting to tear apart my R75 to try its starter on the R90, then I was going to look into the rebuilt starter, and rebuild it as necessary and send you a check or... well, I was just going to play it by ear.

I am still planning on swapping starters this afternoon, so I'll keep you updated.

Thanks again for showing me tricks throughout the years to bring me to the level of a (semi-)competent airhead mechanic!

I know that I can't do it but someone out there can!

I know that I can't do it but someone out there can!

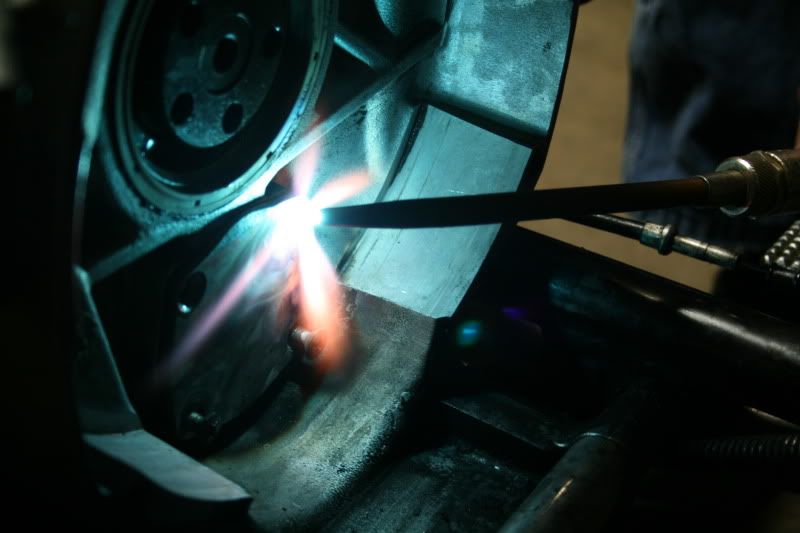

Some more trying and an impact bit experienced catastrophic failure (it killed itself). So, on to the oxy/acetylene torch, after we changed out torch tips (I'd rather not blow a hole through the block). Another impact bit killed itself. More heat.

Some more trying and an impact bit experienced catastrophic failure (it killed itself). So, on to the oxy/acetylene torch, after we changed out torch tips (I'd rather not blow a hole through the block). Another impact bit killed itself. More heat.