Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1100R Scrambler Project

- Thread starter mzeitz

- Start date

What, no radio or GPS? Kidding!

Very nicely done! Keep us updated on future mods.

No but I did call Tesla to see if I could buy one of their autopilots, strangely they haven’t returned my calls....

Sidestand / Gear lever

This morning I cut off and welded the kick loop to the other side of the stand and now there's plenty of clearance and the bike is shifting perfectly (well, as good as before at least, I think the gearbox is kind of clunky but I'm told that's just how they are). Took it out and snapped a few more photos - the last shows the rear shelf and bracket I made for the tag and rear lights...

One major bummer and I'm not sure it shows up in the photo but somehow I ended up with a big scratch on the side of my tank, which was in mint condition before, ugh. It's not too deep though and I'm hoping it will buff out. I think some knobbies would complete the scrambler look but practically most of the riding this thing is going to see is going to be on the road. I'm going to keep an eye out for a spare set of wheels though.

This morning I cut off and welded the kick loop to the other side of the stand and now there's plenty of clearance and the bike is shifting perfectly (well, as good as before at least, I think the gearbox is kind of clunky but I'm told that's just how they are). Took it out and snapped a few more photos - the last shows the rear shelf and bracket I made for the tag and rear lights...

One major bummer and I'm not sure it shows up in the photo but somehow I ended up with a big scratch on the side of my tank, which was in mint condition before, ugh. It's not too deep though and I'm hoping it will buff out. I think some knobbies would complete the scrambler look but practically most of the riding this thing is going to see is going to be on the road. I'm going to keep an eye out for a spare set of wheels though.

I think some knobbies would complete the scrambler look but practically most of the riding this thing is going to see is going to be on the road. I'm going to keep an eye out for a spare set of wheels though.

From what I can see in the photos, I think the tires which are currently on the bike match its present iteration to a "T" - mostly pavement with some dirt roads if you feel like it.

Props to you for this entire build.

Oh, and regarding that clunky gearbox, if you apply upward pressure on the shifter before shifting, and just fan the clutch lever while shifting, it might work better for you.

Oh, and regarding that clunky gearbox, if you apply upward pressure on the shifter before shifting, and just fan the clutch lever while shifting, it might work better for you.

Yeah, it's not so bad once you learn how to shift it; when I first got it I thought there was something wrong with it. But I've gotten used to it...

Oh and Eugene to answer your question you are correct - the photos were taken at Des Moines marina which is just a few minutes from where I live.

Gauge installed

I got the sensor and the gauge installed:

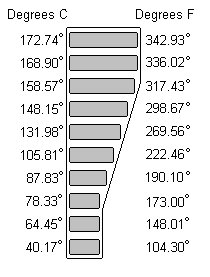

Went out this morning for a "spirited" ride, didn't take it easy at all, including some stop and go, twisty roads and an uphill highway pull doing around 80 (about as fast as is comfortable with no wind screen) for a few miles. Looks like it seems to want to run at around 210. If I was sitting at a red light idling for a few minutes it would creep up to maybe 230 or so but that was as high as I saw. Granted, it's a pretty cool morning so I'll have to see what it does on a really hot day. My gauge reading was dropping out intermittently - when I put it in it was working even though the signal ground was dubious as the oil cooler is mounted on rubber isloators, so I think I just need to ground out the cooler body to the chassis and then it should be ok.

Also just thought of something else - my speedometer reading was always around 4 mph low compared to GPS, I wonder with the larger diameter front wheel what it's going to read now.

I got the sensor and the gauge installed:

Went out this morning for a "spirited" ride, didn't take it easy at all, including some stop and go, twisty roads and an uphill highway pull doing around 80 (about as fast as is comfortable with no wind screen) for a few miles. Looks like it seems to want to run at around 210. If I was sitting at a red light idling for a few minutes it would creep up to maybe 230 or so but that was as high as I saw. Granted, it's a pretty cool morning so I'll have to see what it does on a really hot day. My gauge reading was dropping out intermittently - when I put it in it was working even though the signal ground was dubious as the oil cooler is mounted on rubber isloators, so I think I just need to ground out the cooler body to the chassis and then it should be ok.

Also just thought of something else - my speedometer reading was always around 4 mph low compared to GPS, I wonder with the larger diameter front wheel what it's going to read now.

cam_on_van_isle

Member

Great thread!

Is the oil temp sensor on the inlet or outlet side of the cooler? I'm assuming inlet. My best understanding is that oil temps should be at least 212F in order to evaporate any water typically generated by the combustion process.

Any word back from Tesla yet?

No on that!

Yeah, it's on the inlet side. I still have the oil thermostat on the engine and it is a stock GS cooler so I'm not too concerned about running too cold, but I am concerned about running hot because of the obstruction in front of the cooler. This afternoon I took off the big GS fender and put my R fender back on after some cutting and test fitting (not going to discuss the test ride to check my gauge fix when the rear end of the fender became lodged in the lower cooler bracket...I was wracking my brain riding home trying to figure out why the steering was fighting me all of a sudden), needless to say I have some trimming left to do and I may cut some vents in the back end to direct some air there.

Also just picked up some Acerbis Rally Pro hand guards - was thinking mainly to keep cold wind off my fingers, now that I look at them they are kind of narrow for that purpose but at least they look cool....

gsaddict

Pepperfool

Most Oilheads I have ridden and worked on normally run 5 bars on the RID.

The stock sender sits on top of the motor beside the thermostat where the oil leaving for the cooler is the hottest. I would expect it to be slightly cooler by the time it hits the right side of the oil cooler.

The stock sender sits on top of the motor beside the thermostat where the oil leaving for the cooler is the hottest. I would expect it to be slightly cooler by the time it hits the right side of the oil cooler.

Attachments

Try some brackets directly under your headlight

From the looks of things you have a good eye and talent to back it up so why not look at a couple brackets directly under your headlight. You could also consider a different headlight with a different mounting option.

I considered that option with my 850R scrambler but my path had more options because I eliminated the stock headlight / gauge and idiot light set up. I haven't been back on that project for a while due to my distractions toward other projects, to many other projects and they keep coming.

Here is a few snaps of the most intrusive project, the first one is the before and the others are some of the latest

From the looks of things you have a good eye and talent to back it up so why not look at a couple brackets directly under your headlight. You could also consider a different headlight with a different mounting option.

I considered that option with my 850R scrambler but my path had more options because I eliminated the stock headlight / gauge and idiot light set up. I haven't been back on that project for a while due to my distractions toward other projects, to many other projects and they keep coming.

Here is a few snaps of the most intrusive project, the first one is the before and the others are some of the latest

Attachments

Here is a few snaps of the most intrusive project, the first one is the before and the others are some of the latest

You should start a new thread so we can follow this project independently.

From the looks of things you have a good eye and talent to back it up so why not look at a couple brackets directly under your headlight. You could also consider a different headlight with a different mounting option.

I considered that option with my 850R scrambler but my path had more options because I eliminated the stock headlight / gauge and idiot light set up. I haven't been back on that project for a while due to my distractions toward other projects, to many other projects and they keep coming.

Here is a few snaps of the most intrusive project, the first one is the before and the others are some of the latest

Ah, a basket case - looks like it's coming along nicely though.

I actually considered a couple different options, I looked at mounting above the trailing arm but there isn't room where it doesn't interfere with the suspension and/or steering; the other option being in front of the forks and attached to the steering assembly which is what I think you are talking about. I could weld some tabs to the fork tubes and attach it that way, I'd have to get creative on how to run my hoses - on the stock GS the hoses just come straight out but are hidden by the upper fairings. I saw another GS scrambler done thusly:

I kind of went that route because it looks nice and neat - can't tell how it's mounted, almost looks like it's mounted TO the trailing arm which I didn't do. Also can see some gunk kicked up by the wheel - I have a little better coverage from the fender so should be ok in that respect. Anyway, I'm going to run it for now and see how it works - at the end of the day I don't want to cook the motor so I may end up doing as you suggest.

Most Oilheads I have ridden and worked on normally run 5 bars on the RID.

The stock sender sits on top of the motor beside the thermostat where the oil leaving for the cooler is the hottest. I would expect it to be slightly cooler by the time it hits the right side of the oil cooler.

Thanks for that - in reading up on it I've seen references to the bar gauge and what people have seen for "normal" running temperatures but good to have values to go along with it. I'm assuming that the thermostat would regulate the oil temp so it doesn't get or stay too low - I've noticed since I've been paying attention that mine doesn't open up for a surprisingly long time. And that kind of goes along with what I've seen - my gauge seemed to be reading 210 or a hair above most of the time so far. The top end of my gauge is 300, which I'm sure it's possible to run above that but from what I gather if I'm seeing the upper end of that scale too often I will need to rethink my cooling setup.

If I read the above post correctly (and you certainly don't need my advice) but I wouldn't be mounting the cooler anywhere where the lines are going to be continually flexed.

In the photo it looked to me like the cooler was mounted to the trailing arm in which case the lines would flex with the suspension travel, which I didn't want to do. I guess on the stock GS the cooler is mounted in the "beak" which is stationary, whereas if it was mounted in my case to the forks it wouldn't be obviously. The hoses I used are reinforced and pretty sturdy and I think you could get creative on how they were routed to minimize movement, but then you are introducing stress to the hard lines and etc, so yeah, not ideal.

gsaddict

Pepperfool

Thanks for that - in reading up on it I've seen references to the bar gauge and what people have seen for "normal" running temperatures but good to have values to go along with it. I'm assuming that the thermostat would regulate the oil temp so it doesn't get or stay too low - I've noticed since I've been paying attention that mine doesn't open up for a surprisingly long time. And that kind of goes along with what I've seen - my gauge seemed to be reading 210 or a hair above most of the time so far. The top end of my gauge is 300, which I'm sure it's possible to run above that but from what I gather if I'm seeing the upper end of that scale too often I will need to rethink my cooling setup.

Let it idle without moving on a warm day. Your temperature will come up quickly. Over 300 will damage the oil.

Let it idle without moving on a warm day. Your temperature will come up quickly. Over 300 will damage the oil.

I make a point of not running it for too long sitting still; if it's a hot day I will even shut it down if I know I'm at a long red light. It's the stop/go or very slow moving traffic that sucks to deal with. Speaking of which, I got stuck in a jam at about walking pace for almost an hour riding around the north shore of Oahu on a Road King a couple months ago. The way those things idle I was feathering the clutch almost the entire time; when I stopped afterwards my left hand was so cramped up I literally had to peel my fist apart with my other hand to straighten my fingers....