olironrider

Active member

I got to thinking about a few of the recent posts turning into “Chain Reaction Projects” !

I’ve “been there, done that” with the many stray air-cooled Motorrads I’ve brought home to restore/refurbish; seems the further you dig, the more you find. This thread is dedicated to those Skunks you’ve found !

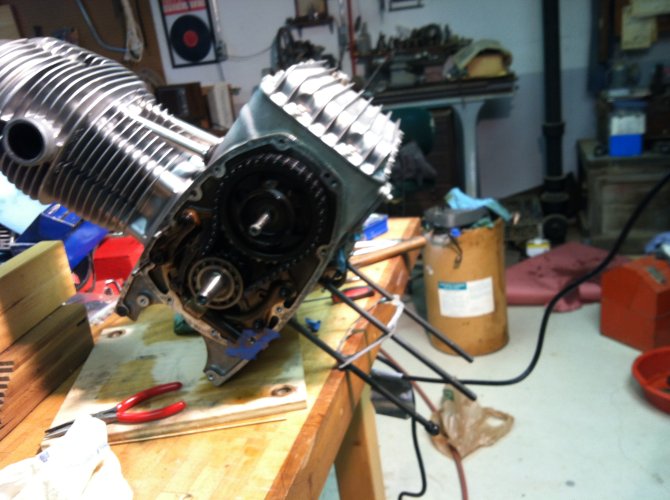

1972 R 60/5 SWB: disassembled “barn find” that had a litter of them, here’s one…

“Remove Cap Before Adding Gear Oil” ! Heard something rattling in Rear Drive while cleaning it before opening to re-seal

I’ve “been there, done that” with the many stray air-cooled Motorrads I’ve brought home to restore/refurbish; seems the further you dig, the more you find. This thread is dedicated to those Skunks you’ve found !

1972 R 60/5 SWB: disassembled “barn find” that had a litter of them, here’s one…

“Remove Cap Before Adding Gear Oil” ! Heard something rattling in Rear Drive while cleaning it before opening to re-seal