zenwhipper

Member

I'm in the - I think one should get a new Akra can if they want one - camp. In fact, I am going to procure said unit in January for my '16RT. To heck with the nay sayers.

And... everything I have read, no new mapping is needed.

Cheers.

And... everything I have read, no new mapping is needed.

Cheers.

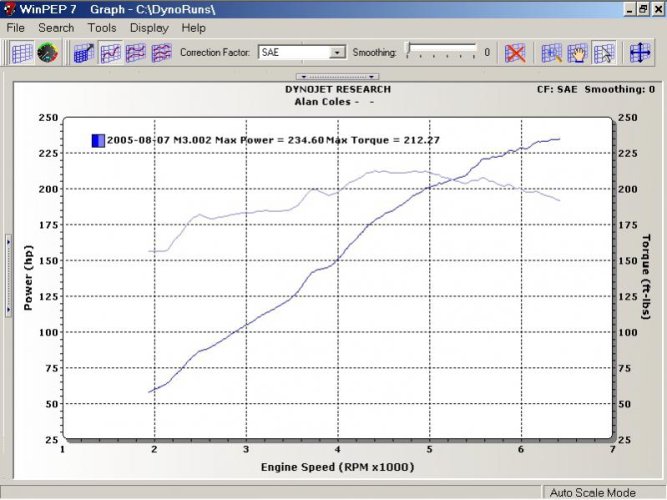

I spent 4K for this-

I spent 4K for this-