gtgt_bangbang

New member

Race Tech Cartridge Emulators "gold valves". Reading list & my set up (78 R100 )

Race Tech site has a bit of good material, worksheets, install and tuning instructions scattered about.

Below are links to pages there I found useful.

in a 78 R100 (36mm tube), I'm installing a FEGV 3301 kit from ebay vendor , with .95 kg/mm main springs from RT, and 15wt oil.

RT lists their x-3308 kit for this BMW app while the 3301 kit was listed for 6 pages of smallish dirt bikes, however all parts are identical &or included.

I suspect the only differences between the kits are

1) ~1" tube spacers tossed in the box,

2) different factory pre set ( easily checked and commonly changed + all the possible swap parts included with 3301.)

3) 80 bucks

Kit came with

a pair cartridge emulators (aka gold valves.) I was big sad to discover Gold Valves are actually made of brass. & RT KNOWS this is a BEEMER, TOO !

4 sets of valve springs for tuning,

a "low speed valve plate" installed, drilled with 3 ports (RT's pre-set for dirt bike).

plus a set of spare, un-drilled valve plates,

and enough stickers to paper over a small bathroom or large tool box.

There is a worksheet with basic info & a nuclear-football-length code to access a Set Up calculator at RT.

RE 'low speed valve plate PORTS" .

RT lit says in one place that "4 ports is common for vintage" and elsewhere says 2 ports are usually best for street / this bike weight / fork tube diameter.

So obviously a little wiggle room exists in the variable.

The plates are dimpled for drill starting, and a dot of solder would plug any unwanted/excess holes.

The low speed ports modulate relatively slow movements like brake-dive and road undulations.

RT tech said the 3301 kit is probably just fine , as-is, for my install, and " tune'em if you wanna".

Stock BMW main springs were ~ .6 rate, but that rate is apparently a (low) compromise to make original orifice-controlled dampening functional.

(desirable , higher rate main springs cause higher rebound rates, which is more prone to rebound cavitation with original, orifice-control system)

The .95 rate , a fairly high spec from RT's calculators, were picked to cover all my expected situations,

I might end up with a set of .85 springs to swap in for solo, lightly loaded, easy-going putt putts on real life roads , if the ride is too stiff.

RT springs are muy shorter than stock, NON-progressive (RT says DONT use progressive), hardened/peened , of some alloy / source which RT is quite proud of.

Mainspring "preload" will be calculated and on the order of a few mm.

Massive preloads are neither necessary nor useful; high preload was another 'fix' for weak-springed, touchy orifice systems.

Shorter springs ( than stock) are required due to the added length of the spacer & GV.

Springs came with a foot of ABS spacer tube

and enough stickers to cover the GV kit's stickers .

model specific products

https://racetech.com/ProductSearch/12/BMW/R100S/1978

RACE TECH EMULATOR FITTING REQUIREMENTS

https://racetech.com/download/IP_FEGV_FIT_web.pdf

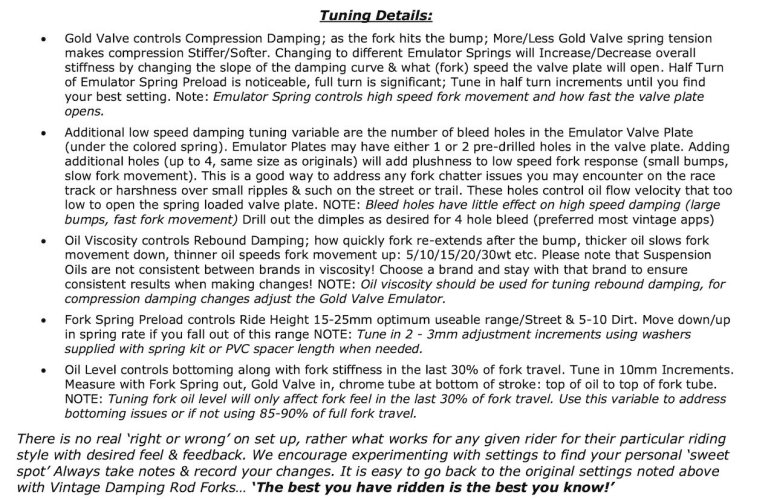

GOLD VALVE CARTRIDGE EMULATOR TUNING GUIDE Dirt and Street

https://www.racetech.com/page/title/...Tuning Guide

EMULATOR FITTING REQUIREMENTS FOR UNLISTED MODELS

https://racetech.com/page/title/Emulator Fitting

Vintage & Damping Rod Style Fork: Set Up & Tuning Guide

https://racetech.com/download/IP F...AGE v3.0.pdf

Fork Seals stock list

https://racetech.com/page/title/FK Seals

ALL DOWNLOADS PAGE

https://www.racetech.com/page/id/100

Race Tech site has a bit of good material, worksheets, install and tuning instructions scattered about.

Below are links to pages there I found useful.

in a 78 R100 (36mm tube), I'm installing a FEGV 3301 kit from ebay vendor , with .95 kg/mm main springs from RT, and 15wt oil.

RT lists their x-3308 kit for this BMW app while the 3301 kit was listed for 6 pages of smallish dirt bikes, however all parts are identical &or included.

I suspect the only differences between the kits are

1) ~1" tube spacers tossed in the box,

2) different factory pre set ( easily checked and commonly changed + all the possible swap parts included with 3301.)

3) 80 bucks

Kit came with

a pair cartridge emulators (aka gold valves.) I was big sad to discover Gold Valves are actually made of brass. & RT KNOWS this is a BEEMER, TOO !

4 sets of valve springs for tuning,

a "low speed valve plate" installed, drilled with 3 ports (RT's pre-set for dirt bike).

plus a set of spare, un-drilled valve plates,

and enough stickers to paper over a small bathroom or large tool box.

There is a worksheet with basic info & a nuclear-football-length code to access a Set Up calculator at RT.

RE 'low speed valve plate PORTS" .

RT lit says in one place that "4 ports is common for vintage" and elsewhere says 2 ports are usually best for street / this bike weight / fork tube diameter.

So obviously a little wiggle room exists in the variable.

The plates are dimpled for drill starting, and a dot of solder would plug any unwanted/excess holes.

The low speed ports modulate relatively slow movements like brake-dive and road undulations.

RT tech said the 3301 kit is probably just fine , as-is, for my install, and " tune'em if you wanna".

Stock BMW main springs were ~ .6 rate, but that rate is apparently a (low) compromise to make original orifice-controlled dampening functional.

(desirable , higher rate main springs cause higher rebound rates, which is more prone to rebound cavitation with original, orifice-control system)

The .95 rate , a fairly high spec from RT's calculators, were picked to cover all my expected situations,

I might end up with a set of .85 springs to swap in for solo, lightly loaded, easy-going putt putts on real life roads , if the ride is too stiff.

RT springs are muy shorter than stock, NON-progressive (RT says DONT use progressive), hardened/peened , of some alloy / source which RT is quite proud of.

Mainspring "preload" will be calculated and on the order of a few mm.

Massive preloads are neither necessary nor useful; high preload was another 'fix' for weak-springed, touchy orifice systems.

Shorter springs ( than stock) are required due to the added length of the spacer & GV.

Springs came with a foot of ABS spacer tube

and enough stickers to cover the GV kit's stickers .

model specific products

https://racetech.com/ProductSearch/12/BMW/R100S/1978

RACE TECH EMULATOR FITTING REQUIREMENTS

https://racetech.com/download/IP_FEGV_FIT_web.pdf

GOLD VALVE CARTRIDGE EMULATOR TUNING GUIDE Dirt and Street

https://www.racetech.com/page/title/...Tuning Guide

EMULATOR FITTING REQUIREMENTS FOR UNLISTED MODELS

https://racetech.com/page/title/Emulator Fitting

Vintage & Damping Rod Style Fork: Set Up & Tuning Guide

https://racetech.com/download/IP F...AGE v3.0.pdf

Fork Seals stock list

https://racetech.com/page/title/FK Seals

ALL DOWNLOADS PAGE

https://www.racetech.com/page/id/100