fredheiler@aol.com

Member

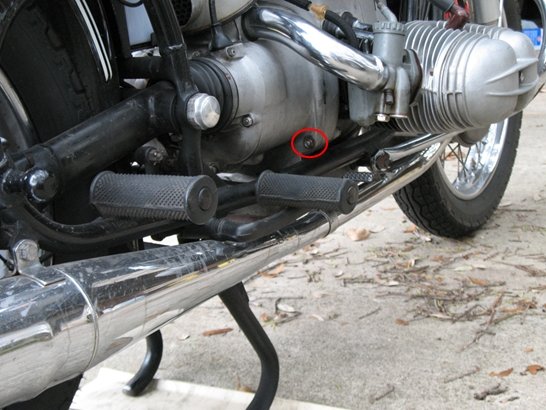

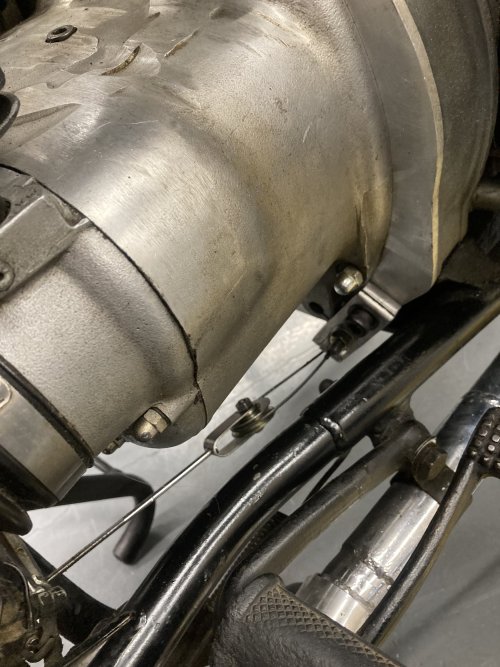

I installed my R75/5 clutch just like the Clymer book said: no mention of the six spacers shown in the fiche drawing. Now that the trans is in, the clutch is very tough to pull in, and doesn't fully disengage. Without the spacers, I'm guessing the diaphragm spring is depressed too far.

Anyone else ever make this screwup? Am I missing something, or should I just pull the trans and reinstall the clutch with the spacers?

Anyone else ever make this screwup? Am I missing something, or should I just pull the trans and reinstall the clutch with the spacers?