I confirmed that the controller on my bike (the one that started this thread) is dead. No voltage output at its connector now. Cut the connector off, made a jumper, plugged it into the front accessory outlet (rated at 10A on the 08RT, it runs the 7A pump fine).

Bike starts and runs normally with the jumper, pump can be heard to run continuously as expected. The jumper, of course, has to be unplugged when stopped or ot will kill the battery pretty fast with that 7A draw.

Going by a dealer tomorrow to get a replacement and spare. Will expect to have the dead one covered on warranty and will report on that- after all I saved them the cost of a tow and dealer repair.

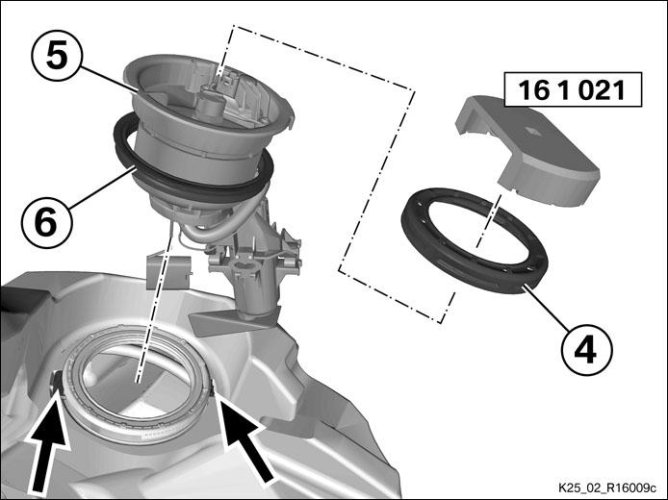

At least a jumper should be in your roadside parts kit- its cheap insurance. Of course, you have know how to pull the left cover (T-25 screws) and the controller (T-20 screws) to employ the jumper and you have to know the controller is the problem in the first place.

Some of them have been reported to fail from heat but if I saw water in the well, GS-911 available to confirm the matching 10198 code or not, I'd be reaching for that jumper if my bike went dead (and I didn't have an EWS error or dead battery)

Despite the fins on the controller, no internal parts contact the housing to eliminate heat and remember that 7A or about 90W pass through it. Instead, the parts are sunk into insulating silicon rubber that doesn't even keep water out. On mine, it has shrunk away from the wires and the edge and there were a couple very slightly corroded connections on the board so it is a bit hard to tell if mine died from water or heat.

Bike starts and runs normally with the jumper, pump can be heard to run continuously as expected. The jumper, of course, has to be unplugged when stopped or ot will kill the battery pretty fast with that 7A draw.

Going by a dealer tomorrow to get a replacement and spare. Will expect to have the dead one covered on warranty and will report on that- after all I saved them the cost of a tow and dealer repair.

At least a jumper should be in your roadside parts kit- its cheap insurance. Of course, you have know how to pull the left cover (T-25 screws) and the controller (T-20 screws) to employ the jumper and you have to know the controller is the problem in the first place.

Some of them have been reported to fail from heat but if I saw water in the well, GS-911 available to confirm the matching 10198 code or not, I'd be reaching for that jumper if my bike went dead (and I didn't have an EWS error or dead battery)

Despite the fins on the controller, no internal parts contact the housing to eliminate heat and remember that 7A or about 90W pass through it. Instead, the parts are sunk into insulating silicon rubber that doesn't even keep water out. On mine, it has shrunk away from the wires and the edge and there were a couple very slightly corroded connections on the board so it is a bit hard to tell if mine died from water or heat.