Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome! You are currently logged out of the forum. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please LOG IN!If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the benefits of membership? If you click here, you have the opportunity to take us for a test ride at our expense. Enter the code 'FORUM25' in the activation code box to try the first year of the MOA on us!

Head nuts

- Thread starter rado360

- Start date

More options

Who Replied?

B

BMWRich58

Guest

8nm, according to 1150RT CD repair manual.

16 ft lb's and that's it.

No leaks and it works for me!

NO additional TURN'S/DEGREES

16 ft lb's and that's it.

No leaks and it works for me!

NO additional TURN'S/DEGREES

NO additional TURN'S/DEGREES

Rich, could you double check thoses figures for me,because thats the first I've heard of no additional degrees, and 8 nm equal less than 6 ft. lbs. (nm x .73756 = ft. lbs.) unless I'm reading the conversion chart wrong,and that sure is possible.

Thanks Tim

Rich, could you double check thoses figures for me,because thats the first I've heard of no additional degrees, and 8 nm equal less than 6 ft. lbs. (nm x .73756 = ft. lbs.) unless I'm reading the conversion chart wrong,and that sure is possible.

Thanks Tim

B

BMWRich58

Guest

Yep,Darryl is correct. I miss read your post. Sorry...

Mine is for Valve covers ONLY...

By the way,why are you "redoing your head bolt torque?"

Mine is for Valve covers ONLY...

By the way,why are you "redoing your head bolt torque?"

B

bmwmick

Guest

Thanks Mick,and Rich I,m redoing because I used to own an air head and when I got the oilhead I did the valves the way I did them on my air head,retorque then set valves--but I used clymer to get the torque and found that 90 deg might not be right,anyway I torqued them to the correct angle and now will leave them alone.

Thanks Tim

Thanks Tim

B

BMWRich58

Guest

Hey Tim,I do the same on my airhead before each valve adjustment except...I do not loosen the bolts,then retighten them . Reason is,the previous "owners/tech", torque wrench might be a little off compared to mine. So,if I loosen and retorque to specified number "with my wrench" and his/their torque wrench was a little tighter but showed the same torque value,I just reset the heads to a lighter value and can now expect head gasket leaks to form. So,I just check torque,and don't loosen at all. If it's loose,it will tightenup,if tight,the torque wrench will click. On oilheads,I've never practiced the retorque of the heads before valve adjustments,only after the 600 mile breakin.

globalrider

Alps Adventurer

Lowrider said:...I did the valves the way I did them on my air head, retorque then set valves--

Tim, even on the airhead, you didn't have to re-torque the head nuts every time you wanted to adjust the valves. That is putting a lot of wear and tear (and the chance for a mistake) on the threaded assemblies, especially those in the block which are already so close to the cylinder bore opening.

But you do have to at least check, and possibly adjust the valve clearances after re-torquing the head nuts.

globalrider

Alps Adventurer

You do realize that you can torque a fastener to say 50 lbf.ft. in a continuous motion, then reset your torque wrench to 55 lbf.ft. and chances are very good (probably 100%) that the fastener won't turn any further, yet your torque wrench will click just the same at 55 lbf.ft. without any further torquing taking place.BMWRich58 said:So, I just check torque,and don't loosen at all. If it's loose, it will tightenup, if tight, the torque wrench will click.

You loosen fasteners so that you can correctly re-torque them. Once a fastener is set, you have to overcome static friction to get it rotating further.

Next question. When was your torque wrench last calibrated?

globalrider

Alps Adventurer

Lowrider said:Where can I get the wrench calibrated?

Tim

What make and model? Are they quality wrenches worth calibrating?

The most important aspect is that it is repeatable over time. For that, we are talking a quality torque wrench.

I have three click type Snap-On torque wrenches, two of which I calibrated myself at work. I think Snap-On provides calibration service. They should provide you with a print-out. Chances are they won't do five runs as I've done to check the repeatability of the wrench. If it is a Snap-On, the two that I calibrated had excellent repeatability (tight standard deviation) and accuracy was within specifications even below the top 80% of the working range. One wrench was calibrated 17 years after I bought it.

You really don't care if it is off, as long as you know how much it is off and you can compensate using the print-out.

In the end, fastener finish, oil on the threads, etc have more of an effect than the slight amount your wrench "may" be off. After all, we're not assembling jet engines.

J

JRMSR

Guest

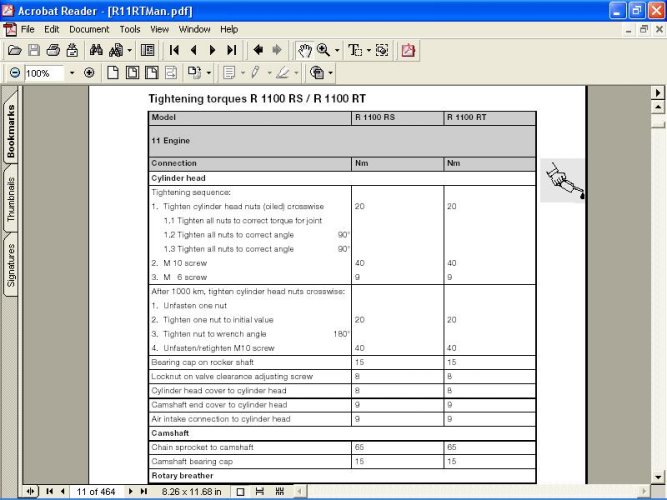

For an oilhead, after removing the cylinder head and reassembling (shouldn't be doing that except for major overhaul), you tighten all 4 nuts slowly to 15 ft/lbs X-cross fashion.

Then you tighten each nut 90?? X-cross fashion, all 4. Then you tighten each nut 90?? X-cross fashion again all 4, to complete.

After doing this once on cylinder head reinstall, you must re-torque after 600 miles of use. On retorque, you loosen one nut at a time, torque it to 15 ft/lbs, then tighten 180??. Then do the next nut in X-cross fashion, till all 4 are done. Also loosen and retorque the M10 nut in cyclinder head.

Again, the difference is whether it is the first time since re-install of cylinder head (90?? all four, then 90?? again) or whether it is the 600 mile retorque after initial assembly (180?? each nut individually).

For valve adjustments only, you should never be loosening, tightening the head nuts.

Jim Morrow

Then you tighten each nut 90?? X-cross fashion, all 4. Then you tighten each nut 90?? X-cross fashion again all 4, to complete.

After doing this once on cylinder head reinstall, you must re-torque after 600 miles of use. On retorque, you loosen one nut at a time, torque it to 15 ft/lbs, then tighten 180??. Then do the next nut in X-cross fashion, till all 4 are done. Also loosen and retorque the M10 nut in cyclinder head.

Again, the difference is whether it is the first time since re-install of cylinder head (90?? all four, then 90?? again) or whether it is the 600 mile retorque after initial assembly (180?? each nut individually).

For valve adjustments only, you should never be loosening, tightening the head nuts.

Jim Morrow