gsaddict

Pepperfool

I prefer to time the following way. (1150's only)

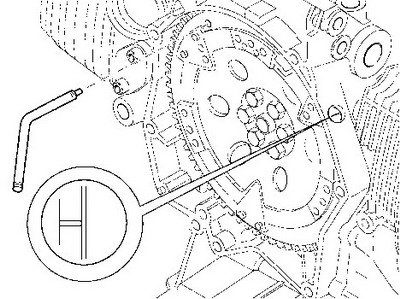

When the sensor plate is in the approximate position....

Turn on the ignition.

Turn the crank CW (via the pulley nut) until the OT mark passes the center of the window

The fuel pump should activate (for 1 sec) right at that point.

Adjust the plate accordingly.

No adapter lead required

When the sensor plate is in the approximate position....

Turn on the ignition.

Turn the crank CW (via the pulley nut) until the OT mark passes the center of the window

The fuel pump should activate (for 1 sec) right at that point.

Adjust the plate accordingly.

No adapter lead required