R60/6..installed rear main seal and oil pump o ring..after test drive I was setting timing when there was a loud click...upon disassembly the oil pump rotor was shattered, cover scored and end of camshaft was broken off. Installed new oil pump, oil pump cover,o ring , timing chain and flushed engine. When tightening oil pump cover the engine tightens up...rotor is binding on cover.Also when I tighten timing chain cover the engine locks up. Anyone have this happen and is there any way to correct or save the engine? Thanks

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome! You are currently logged out of the forum. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please LOG IN!If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the benefits of membership? If you click here, you have the opportunity to take us for a test ride at our expense. Enter the code 'FORUM25' in the activation code box to try the first year of the MOA on us!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Catastrophic oil pump failure R60/6

- Thread starter 13801

- Start date

Welcome to the forum! Can't say as I have much experience with this sort of failure...there's at least one other thread going regarding the oil pump. That said, I've read the strong recommendation that when getting into the oil pump, after removing the flywheel, the crankshaft must be block in the front to prevent it from moving forward. Not sure if this might be related to your issue. Once the crankshaft moves, it's impossible to tighten the flywheel to spec and the engine locks up and won't turn.

olironrider

Active member

Hmmm, you stated: “… shattered, cover scored and end of camshaft was broken off.” How did you: “Installed new oil pump, oil pump cover, o-ring” considering the camshaft condition ?

Oft times, when reinstalling the oil pump inner rotor, the Woodruff Key that keys the inner rotor to the camshaft, gets pushed out and into the suction or pressure sides of the crankcase casting, worse yet… between the oil pump rotors ! If the shattered inner and broken camshaft debris, scored/gouged/smeared the crankcase side of the oil pump casting surfaces, those disturbed surfaces have taken-up the very close clearances between the inner/out rotors to crankcase. The rotors are hardened steel while the crankcase material is aluminum alloy !

That wide web at the top portion in the crankcase oil pump casting, is where suction of the oil from the oil sump get turned into pressure oil for distribution to the main oil gallery, by the interaction of the four lobe inner rotor, rotating within the five lobe outer rotor… we’re talking tight clearances: <0.005” +/- !

A serious inspection of the oil pump area in the crankcase casting, is in order ! The crankcase may well be unserviceable.

As mentioned, prior to starting removal of the flywheel, the crankshaft must be held rearwards against the rear thrust shims and casting by some means ! I remove the alternator rotor center bolt; install a M8-1.25 X 30mm socket head bolt with nut and plain washer in its place; turn the bolt in leaving enough exposed so that when temporarily installing the front engine cover, the cover bears against the bolt sufficiently to thrust the crankshaft to the rear… this is a repeated: fit & test situation.

Upon being certain crankshaft it positioned rearward, remove the front engine cover; unscrew the “pusher bolt” one turn and lock it down with the nut. Reinstall the front cover with all three socket head screws; hand torque to firmly hold the “ pusher bolt” and crankshaft to the rear; look for a small perimeter gap of the front cover to chain case cover.

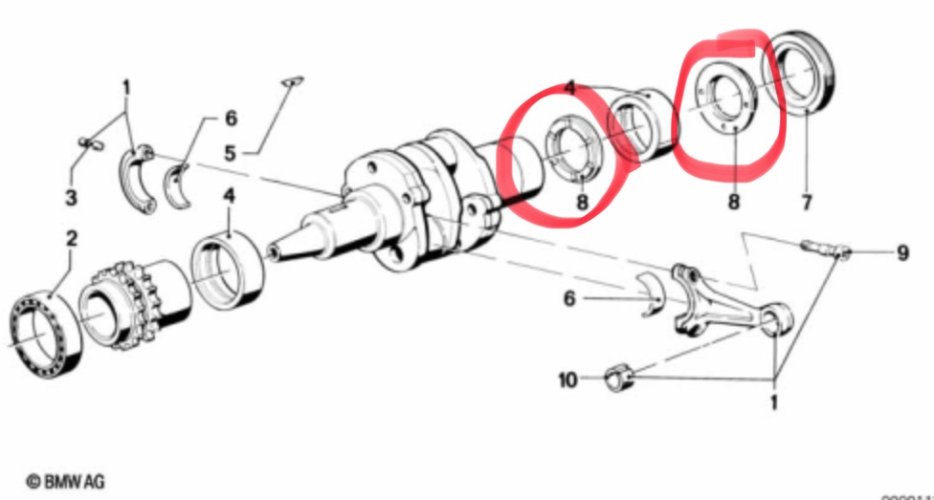

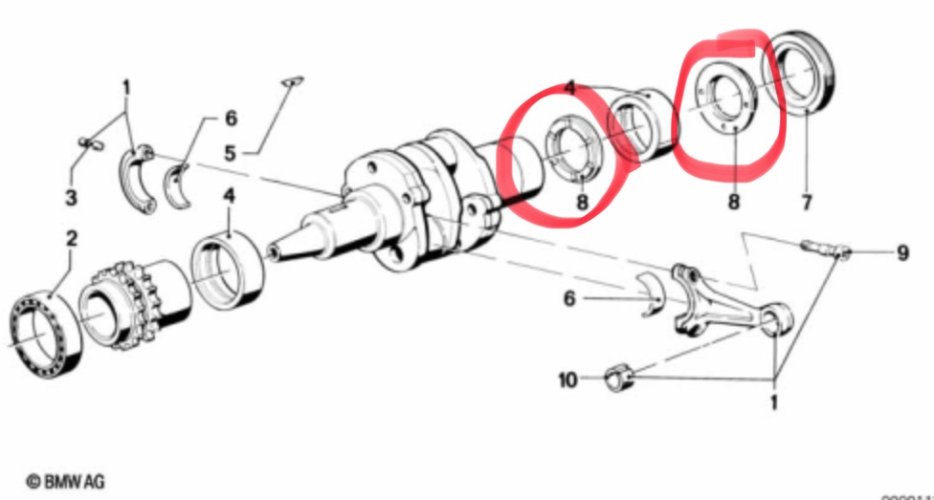

Still and all, careful attention must be paid to insure both rear crankshaft thrust shims remain on their locating pins ! “… when I tighten timing chain cover the engine locks up.”, tells me that was not the case.

Oft times, when reinstalling the oil pump inner rotor, the Woodruff Key that keys the inner rotor to the camshaft, gets pushed out and into the suction or pressure sides of the crankcase casting, worse yet… between the oil pump rotors ! If the shattered inner and broken camshaft debris, scored/gouged/smeared the crankcase side of the oil pump casting surfaces, those disturbed surfaces have taken-up the very close clearances between the inner/out rotors to crankcase. The rotors are hardened steel while the crankcase material is aluminum alloy !

That wide web at the top portion in the crankcase oil pump casting, is where suction of the oil from the oil sump get turned into pressure oil for distribution to the main oil gallery, by the interaction of the four lobe inner rotor, rotating within the five lobe outer rotor… we’re talking tight clearances: <0.005” +/- !

A serious inspection of the oil pump area in the crankcase casting, is in order ! The crankcase may well be unserviceable.

As mentioned, prior to starting removal of the flywheel, the crankshaft must be held rearwards against the rear thrust shims and casting by some means ! I remove the alternator rotor center bolt; install a M8-1.25 X 30mm socket head bolt with nut and plain washer in its place; turn the bolt in leaving enough exposed so that when temporarily installing the front engine cover, the cover bears against the bolt sufficiently to thrust the crankshaft to the rear… this is a repeated: fit & test situation.

Upon being certain crankshaft it positioned rearward, remove the front engine cover; unscrew the “pusher bolt” one turn and lock it down with the nut. Reinstall the front cover with all three socket head screws; hand torque to firmly hold the “ pusher bolt” and crankshaft to the rear; look for a small perimeter gap of the front cover to chain case cover.

Still and all, careful attention must be paid to insure both rear crankshaft thrust shims remain on their locating pins ! “… when I tighten timing chain cover the engine locks up.”, tells me that was not the case.

olironrider

Active member

… following-up on the Crankshaft Blocking Bolt and while I’m at it, these are my set-ups for blocking the crankshaft to the rear of the engine as well as, the Clutch Jacking Bolts.

Crankshaft Blocking Bolt is: M8-1.25 X 25mm; it’s still set at the threaded length I used last, 17mm.

Clutch Jacking Bolts are: M8-1.0 X 40mm.

I used hex head as the 13mm wrench(s) used to block the crank are also used to jack the pressure ring.

Don

Crankshaft Blocking Bolt is: M8-1.25 X 25mm; it’s still set at the threaded length I used last, 17mm.

Clutch Jacking Bolts are: M8-1.0 X 40mm.

I used hex head as the 13mm wrench(s) used to block the crank are also used to jack the pressure ring.

Don

Thanks ..back on engine today..will reply when I settle inHmmm, you stated: “… shattered, cover scored and end of camshaft was broken off.” How did you: “Installed new oil pump, oil pump cover, o-ring” considering the camshaft condition ?

Oft times, when reinstalling the oil pump inner rotor, the Woodruff Key that keys the inner rotor to the camshaft, gets pushed out and into the suction or pressure sides of the crankcase casting, worse yet… between the oil pump rotors ! If the shattered inner and broken camshaft debris, scored/gouged/smeared the crankcase side of the oil pump casting surfaces, those disturbed surfaces have taken-up the very close clearances between the inner/out rotors to crankcase. The rotors are hardened steel while the crankcase material is aluminum alloy !

That wide web at the top portion in the crankcase oil pump casting, is where suction of the oil from the oil sump get turned into pressure oil for distribution to the main oil gallery, by the interaction of the four lobe inner rotor, rotating within the five lobe outer rotor… we’re talking tight clearances: <0.005” +/- !

A serious inspection of the oil pump area in the crankcase casting, is in order ! The crankcase may well be unserviceable.

As mentioned, prior to starting removal of the flywheel, the crankshaft must be held rearwards against the rear thrust shims and casting by some means ! I remove the alternator rotor center bolt; install a M8-1.25 X 30mm socket head bolt with nut and plain washer in its place; turn the bolt in leaving enough exposed so that when temporarily installing the front engine cover, the cover bears against the bolt sufficiently to thrust the crankshaft to the rear… this is a repeated: fit & test situation.

Upon being certain crankshaft it positioned rearward, remove the front engine cover; unscrew the “pusher bolt” one turn and lock it down with the nut. Reinstall the front cover with all three socket head screws; hand torque to firmly hold the “ pusher bolt” and crankshaft to the rear; look for a small perimeter gap of the front cover to chain case cover.

Still and all, careful attention must be paid to insure both rear crankshaft thrust shims remain on their locating pins ! “… when I tighten timing chain cover the engine locks up.”, tells me that was not the case.

View attachment 99842

Thanks...will reply in a short shortWelcome to the forum! Can't say as I have much experience with this sort of failure...there's at least one other thread going regarding the oil pump. That said, I've read the strong recommendation that when getting into the oil pump, after removing the flywheel, the crankshaft must be block in the front to prevent it from moving forward. Not sure if this might be related to your issue. Once the crankshaft moves, it's impossible to tighten the flywheel to spec and the engine locks up and won't turn.

Did block engine...thrush washers are still on… following-up on the Crankshaft Blocking Bolt and while I’m at it, these are my set-ups for blocking the crankshaft to the rear of the engine as well as, the Clutch Jacking Bolts.

Crankshaft Blocking Bolt is: M8-1.25 X 25mm; it’s still set at the threaded length I used last, 17mm.

Clutch Jacking Bolts are: M8-1.0 X 40mm.

View attachment 99845

I used hex head as the 13mm wrench(s) used to block the crank are also used to jack the pressure ring.

Don

On my page it says "angry"....I am not angry ..I am very thankfulful for input...heading to get back on engine....last time I tighten oil pump cover the engine did not tighten...Crazy!...,.will remove and retighten cover and see what happens.… following-up on the Crankshaft Blocking Bolt and while I’m at it, these are my set-ups for blocking the crankshaft to the rear of the engine as well as, the Clutch Jacking Bolts.

Crankshaft Blocking Bolt is: M8-1.25 X 25mm; it’s still set at the threaded length I used last, 17mm.

Clutch Jacking Bolts are: M8-1.0 X 40mm.

View attachment 99845

I used hex head as the 13mm wrench(s) used to block the crank are also used to jack the pressure ring.

Don

PumpR60/6..installed rear main seal and oil pump o ring..after test drive I was setting timing when there was a loud click...upon disassembly the oil pump rotor was shattered, cover scored and end of camshaft was broken off. Installed new oil pump, oil pump cover,o ring , timing chain and flushed engine. When tightening oil pump cover the engine tightens up...rotor is binding on cover.Also when I tighten timing chain cover the engine locks up. Anyone have this happen and is there any way to correct or save the engine? Thanks

Today disassembled engine again..oiled and reinstalled oil pump...engine would turn...found no reason why it locked up before. Carefully heated timing chain cover and slowly tightened bolts on crisscross pattern...engine developed a bit of a drag but would turn with a little effort Tapping the crank shows a little movement fore and back. Where do I measure play? Thinking I will remove cover and replace gasket and seals again then carefully reinstall cover. If it operates with light drag go ahead with piston ,rods.heads and valves..reinstall engine ,crank and check for oil pressure and noise. As a note ..had a Machinist check measurements..he felt they were ok and had no idea why it was locking up some times. Pretty nervous about not having a definite cause of issues.. I do have new camshaft and followers to install after original cam broke.Thanks ..back on engine today..will reply when I settle in

Similar threads

- Replies

- 25

- Views

- 3K

- Replies

- 10

- Views

- 3K

- Replies

- 8

- Views

- 2K