Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome! You are currently logged out of the forum. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please LOG IN!If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the benefits of membership? If you click here, you have the opportunity to take us for a test ride at our expense. Enter the code 'FORUM25' in the activation code box to try the first year of the MOA on us!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'84 R100RT Leaking between cases..

- Thread starter RAColeman

- Start date

I agree with all of you. I think the problem is going to be finding the parts. The Old "Trails End BMW" is selling Enfields, The new one is with the harley shop.

I'll look on line today.

Thanks

Bob

George seems to be still doing some work. I stopped by there last week to see about getting my exhaust valve recession taken care of and he was still willing to take in work.

BTW, your bike looks exactly like mine. Same paint color...

RAColeman

AKBob

Hi I'm Bob and

I'm a thief of good IDEAS.

However I don't Bogart praise.

Thanks to All that have contributed so far.

The BD (BMW Doctor) aka Geo. may make a house call but it looks like I changed my mind. I did some cleaning before pulling the Flywheel, Bad Idea..

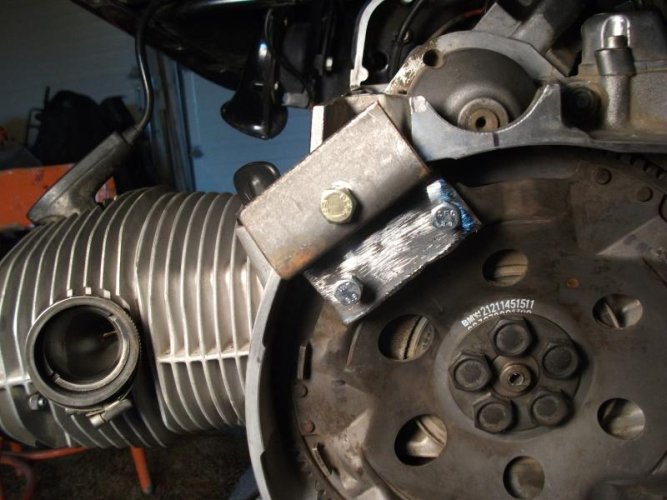

Special Tools .. Made a trip over to C&R Pipe, I got enough steel to make a flywheel holder thing a crazzydrummerdude for everyone with a AirHead in Fairbanks and the suronding area.

I'm a thief of good IDEAS.

However I don't Bogart praise.

Thanks to All that have contributed so far.

The BD (BMW Doctor) aka Geo. may make a house call but it looks like I changed my mind. I did some cleaning before pulling the Flywheel, Bad Idea..

Special Tools .. Made a trip over to C&R Pipe, I got enough steel to make a flywheel holder thing a crazzydrummerdude for everyone with a AirHead in Fairbanks and the suronding area.

Attachments

RAColeman

AKBob

Parts list.. and another pic.

Motor

1 - 11111338342 Shaft Seal $28.16

1 - 11411335895 O-Ring Oil Pump $$4.33

5 - 11221262060 Hex Bolt $13.95 (for fly wheel) BD says I've been reading to much and a new one could break too if over torqued. What you guys think?

Tranny BD says the tranny aint leaking.

1 - 23121338726 Shaft Seal $10.24

1 - 2311338740 Shaft Seal $8.59

1 - 61311355262 Gasket Ring $.89

works out to about $66.52 unless I'm missing something. Am I?

Motor

1 - 11111338342 Shaft Seal $28.16

1 - 11411335895 O-Ring Oil Pump $$4.33

5 - 11221262060 Hex Bolt $13.95 (for fly wheel) BD says I've been reading to much and a new one could break too if over torqued. What you guys think?

Tranny BD says the tranny aint leaking.

1 - 23121338726 Shaft Seal $10.24

1 - 2311338740 Shaft Seal $8.59

1 - 61311355262 Gasket Ring $.89

works out to about $66.52 unless I'm missing something. Am I?

Attachments

T

TGHSMITH

Guest

very glad to see you are marking everything well so the clutch goes back together balanced and the timing mrks line up, two cents worth, put something more positive to block the crank(long board and straps(not bungies!) its one of those very oh s**t deals...

crazydrummerdude

advrider.com

very glad to see you are marking everything well so the clutch goes back together balanced and the timing mrks line up, two cents worth, put something more positive to block the crank(long board and straps(not bungies!) its one of those very oh s**t deals...

Whatever you use, make sure you've got pressure against the front cover when it's reinstalled over the board.. and make sure you install the front cover before taking off the flywheel (I hope you did). The tape isn't the thing keeping the crankshaft back in its place.

T

TGHSMITH

Guest

just my two cents, too important to do blind, threads in the timing chain cover too important to risk damage(and hard to repair), piece of 2x4(or the like) crosswise with a strap around each cylinder base holds everthing straight the the crank..

RAColeman

AKBob

Maybe a ah Shucks

OOPS.

The block of wood and cover went on after the Flywheel came out.

The Flywheel came off easy, one bolt would not turn out with my fingers after breaking them loose but I wasn't putting any real pressure on anything after breaking them loose. The tape was there just to hold the wood in place while putting the cover on. The cover dosn't close completely at the bottom. I could feel the pressure building up as the cover bolts went in. Figured snug was good and didn't get ham fisted.

Parts are on order. Planing to replace all the seals, leaking or not. They are 27 years old.

Any body think I'm messing up?

OOPS.

The block of wood and cover went on after the Flywheel came out.

The Flywheel came off easy, one bolt would not turn out with my fingers after breaking them loose but I wasn't putting any real pressure on anything after breaking them loose. The tape was there just to hold the wood in place while putting the cover on. The cover dosn't close completely at the bottom. I could feel the pressure building up as the cover bolts went in. Figured snug was good and didn't get ham fisted.

Parts are on order. Planing to replace all the seals, leaking or not. They are 27 years old.

Any body think I'm messing up?

Attachments

Any body think I'm messing up?

I think you'll find out when you bolt everything back up. If you bolt up the flywheel and at some point in the tightening process, the engine doesn't turn anymore, then the thrust washers came off their pegs. At that point, you have to figure out how to get them back on. IIRC, one can come back in through one of the case openings, after completing removing the top end.

RAColeman

AKBob

Hurry up and wait

The parts are on order. Nothing I'm gonna do to speed that up.

Started cleaning up the Carborators, Got a Stuck screw on one, WD40 and Breakfree and TIME I got lots of it. Just a touch of antiseize would have saved me a bunch of grief.

Started reading about reassembly and making a list of sundries, loctite, ThreeBond 1216 aka Hondabond HT, Guard Dog GD-525 molly for the splines.

The top left bolt in the oilpump cover seemed lets say Not tite, and all had some sort of grey gunk on them. There was no sign of any sealant on the pump flanges or cover. The hondabond ht and loctite are in town so they will get put on the oilpump today, 72 hrs + + + easy before start up.

The parts are on order. Nothing I'm gonna do to speed that up.

Started cleaning up the Carborators, Got a Stuck screw on one, WD40 and Breakfree and TIME I got lots of it. Just a touch of antiseize would have saved me a bunch of grief.

Started reading about reassembly and making a list of sundries, loctite, ThreeBond 1216 aka Hondabond HT, Guard Dog GD-525 molly for the splines.

The top left bolt in the oilpump cover seemed lets say Not tite, and all had some sort of grey gunk on them. There was no sign of any sealant on the pump flanges or cover. The hondabond ht and loctite are in town so they will get put on the oilpump today, 72 hrs + + + easy before start up.

Attachments

What screw? One of the 4 that hold the cover down? Use a clamp-affair to hold a screwdriver bit in the head of the screw while protecting the underside of the carb top. Then use a open end wrench to turn the bit to unscrew. Keep vertical pressure on the bit, relaxing a bit as the screw turns out. Of course, penetrating oil is definitely called for.

M

mymindsok

Guest

I think you'll find out when you bolt everything back up. If you bolt up the flywheel and at some point in the tightening process, the engine doesn't turn anymore, then the thrust washers came off their pegs. At that point, you have to figure out how to get them back on. IIRC, one can come back in through one of the case openings, after completing removing the top end.

Well, my experience is this: Once you realize that the flywheel bolts are tightened to the point that the flywheel won't turn, you've already damaged one or both of the crank shims and they'll need to be replaced. In fact, just one year ago, I watched my local "Professional Airhead Mechanic" destroy both crank shims in my R90's engine, doing just that. In fact, he was dumb enough that he not only damaged the shims but ruined the locating pins and the rear surface of the block as well and didn't take a lot of force to do it! (Remember... The block is aluminum!) Please note that the "out of court settlement" for the repair bill came to $4000 plus.

If you even think that you might have dropped those shims off of their pins you absolutely must pull off at least the entire left side top end, so that you can check and reposition the internal shim onto it's pins if necessary. There are no short cuts. You'll need to check the rear shim, by pulling the flywheel off again.

If you do damage the internal shim, you'll be looking forward to a complete engine tear down and maybe a $200 machine shop bill, before you rebuild your engine. Why do I say rebuild? Because you'll be so far into that engine that you may as well rebuild it!

Blocking the crank is no joke and even a professional can make that costly mistake.

BLOCK THAT CRANK AND LEAVE IT BLOCKED!!!

Last edited:

RAColeman

AKBob

Screw is out! Seals on the tranny are in!

An End Mill is an amazing maching. First try was to cut a slot and see if she would come out. Screw is out, never again without antiseize!

The front seal on the tranny was badly warn, the shifter seal needed replacing too. The main rear tranny seal is still there a regular puller wasn't doing it and so the washer and nut went back on.

The Huddy's came by and signed my mileage contest varification.

The plan is Kinda comming together again.

An End Mill is an amazing maching. First try was to cut a slot and see if she would come out. Screw is out, never again without antiseize!

The front seal on the tranny was badly warn, the shifter seal needed replacing too. The main rear tranny seal is still there a regular puller wasn't doing it and so the washer and nut went back on.

The Huddy's came by and signed my mileage contest varification.

The plan is Kinda comming together again.

Attachments

crazydrummerdude

advrider.com

The top of the Bings is the perfect place for an appropriately supported impact..

Any pics of the end mill setup?

Any pics of the end mill setup?

T

TGHSMITH

Guest

that nut and washer on the gearbox rear drive needs to go on dry with 160lbs very hard to do without a special tool... very bad if the drive flange slips...

RAColeman

AKBob

Doomed? I Feel Great for a dead man walking

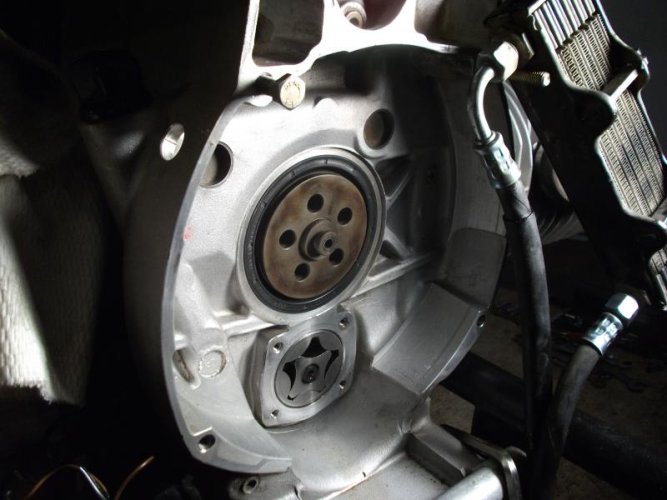

The old seal came out easy. Three small holes in the old seal, 3 little roberts head screws went in little vice grip, Granny screw driver, piece of wood to pad the case, Pop it was out.

The oil pump cover got a new o ring, Hondabond HT on the mating serface (crankcase), Loctite on the bolts. Torqued to spec. Dog I hope this works!

The new style Rear main seal was just plain weird. Let the whole thing swim in 20W50 in the bag it came in for a long while, bent the lip over and worked it around and around. I never poped off the spacer ? part on the end of the shaft, so putting the seal on with the lip bent in was a bit of a booger. Used a dull pointy thing to work in in at the bottom, rest went fine. Figure if I put a whole in it I'll know pretty quick. Double Dog I hope this works!!

Snugged up the front cover bolts. Boy thoes Flywheels are a TIGHT FIT, till their in position. Started to lock it in position with my homade tool, loose. Oiled up the new flywheel bolts, turned em in by hand, snugged them with a scoket by hand, locked the locking tool in place. Torqued them to 30, then 40, then 50, then 60, Then 75 LBS. Tripple Dog I hope this works!!!

Pulled the lockers off and turned it over by hand. It goes round and round no scraping noise.

Does that mean I did good? Am I missing something?

The spring thing, plates and friction plate all went in easy. Had a @ 1" dia Bar with a pointy end that kinda worked as a cluch tool, so its all kinda centered. Just snugged it up didn't torque anything.

Now if the GD-525 gets here and the Hondabond woud just set instantly and if I had the tank Por 15'd I might have a bike again..

Crazydrummerdude, Yea but .. The Impact driver tosted the screw. I gotta put the Pale golden Liquid in the nasty brown bottles tomarrow, in Fox AK. If John is over at the shop I'll get you a picture. Till then think REAL BIG Green Machine.

TGHSnith: It rattled off easy, and got rattled back on. Hope it works.

Hey guys I've made a living as a phone guy all my life, Not as a wrench, any body see a screw up? Please let me know...

The old seal came out easy. Three small holes in the old seal, 3 little roberts head screws went in little vice grip, Granny screw driver, piece of wood to pad the case, Pop it was out.

The oil pump cover got a new o ring, Hondabond HT on the mating serface (crankcase), Loctite on the bolts. Torqued to spec. Dog I hope this works!

The new style Rear main seal was just plain weird. Let the whole thing swim in 20W50 in the bag it came in for a long while, bent the lip over and worked it around and around. I never poped off the spacer ? part on the end of the shaft, so putting the seal on with the lip bent in was a bit of a booger. Used a dull pointy thing to work in in at the bottom, rest went fine. Figure if I put a whole in it I'll know pretty quick. Double Dog I hope this works!!

Snugged up the front cover bolts. Boy thoes Flywheels are a TIGHT FIT, till their in position. Started to lock it in position with my homade tool, loose. Oiled up the new flywheel bolts, turned em in by hand, snugged them with a scoket by hand, locked the locking tool in place. Torqued them to 30, then 40, then 50, then 60, Then 75 LBS. Tripple Dog I hope this works!!!

Pulled the lockers off and turned it over by hand. It goes round and round no scraping noise.

Does that mean I did good? Am I missing something?

The spring thing, plates and friction plate all went in easy. Had a @ 1" dia Bar with a pointy end that kinda worked as a cluch tool, so its all kinda centered. Just snugged it up didn't torque anything.

Now if the GD-525 gets here and the Hondabond woud just set instantly and if I had the tank Por 15'd I might have a bike again..

Crazydrummerdude, Yea but .. The Impact driver tosted the screw. I gotta put the Pale golden Liquid in the nasty brown bottles tomarrow, in Fox AK. If John is over at the shop I'll get you a picture. Till then think REAL BIG Green Machine.

TGHSnith: It rattled off easy, and got rattled back on. Hope it works.

Hey guys I've made a living as a phone guy all my life, Not as a wrench, any body see a screw up? Please let me know...

crazydrummerdude

advrider.com

All I can say is; 1) I hope your crankshaft didn't move. I'd hate to be part of a gung-ho-attitude-induced problem, and 2) when I did my oil pump cover, people told me it needed no sealant.

It is what it is.. But, good luck. Keep the pics comin'.

It is what it is.. But, good luck. Keep the pics comin'.

Similar threads

- Replies

- 2

- Views

- 2K

F

- Replies

- 1

- Views

- 5K