I'd be mighty careful about using brake cleaner on bearings. The brake cleaner can do a fine job of removing all of the grease and oil from the surface.

I checked Oak's article. He mentions "solvent" then goes on to specifically say "charcoal starter" fluid as well as chlorinated hydrocarbon cleaner such as 111-Trichloro or Perchlorethane.

I've always been using the product Brakleen....the can says non-chlorinated and contains methanol, acetone, toluene, heptane, and carbon dioxide. Might not be the right stuff per Oak...I've used it often to clean things and then put back in service...always wear gloves.

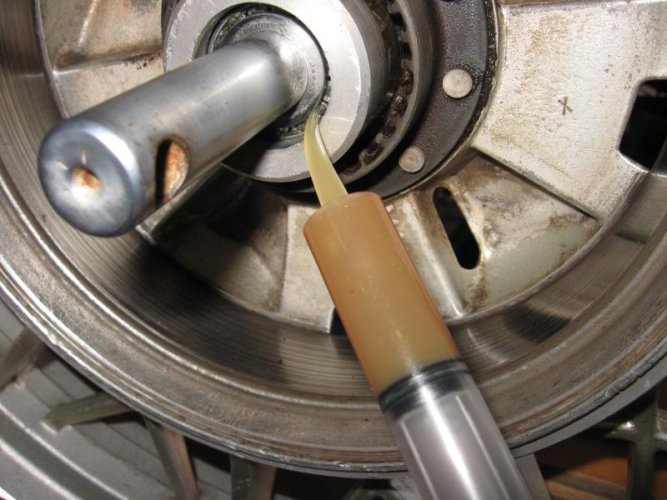

I usually go straight for this stuff...maybe I'll have to look around. Oak does mention to use the solvent and then flush the area. Seems like that would help alleviate any issues that you suggest. Doubt I'd be trying eat a sammich in the middle of all this!