"Benchwrencing" is a huge part of the WHY I read these magazines!

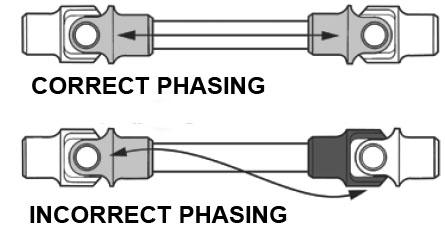

LFarling - Changing the angle of the driveline doesn't change the phasing; phasing is totally dependent on the orientation of the U-joints with respect to each other.

(Side note - How "close" you can get depends on how many teeth are available to slot the pieces into; more teeth = closer alignment).

I've said it before but it needs saying again: I have personally witnessed brand-new shafts still in the BMW packaging that were out of phase. It is up to the mechanic working on the bike to look at what he's doing and do it right.

Of all the you tubes I have watched for the drive shaft service I have not seem the mechanic align the shaft on the splines at the gear box output shaft or the rear gear box. You would think if this was critical an index mark would be present for the alignment. If I look at the drive shaft housing on my 2016 R1200 GS the angle of the shaft from the transmission to the drive shaft is larger than the angle at the rear gear box with the bike on the center stand. Maybe the universal joints are put slightly out of phase to correct the angle difference, of course the angles changed slightly with the bike loaded.