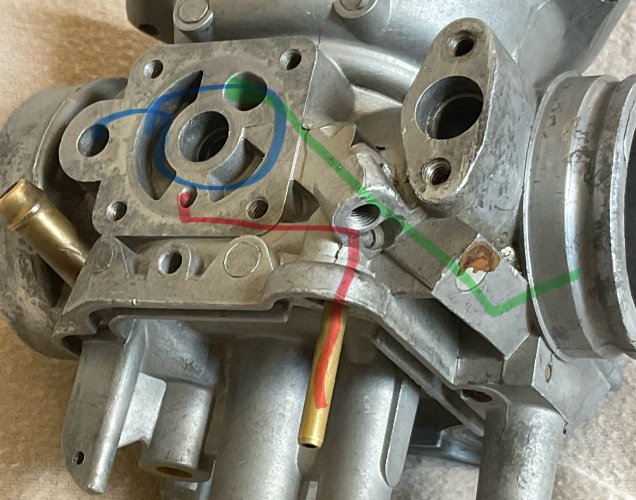

I appreciate all the work you're putting into trying to help me.… on the outlet (engine) side of the carb, there is a drilled & plugged passage through the aft wall of the Idle Mixture screw bore; and the other micro hole, that the needle end of the Idle Mixture screw engages, is drilled into the floor. These are the two ports for the fuel mixture, shown in #17 above.

View attachment 97129

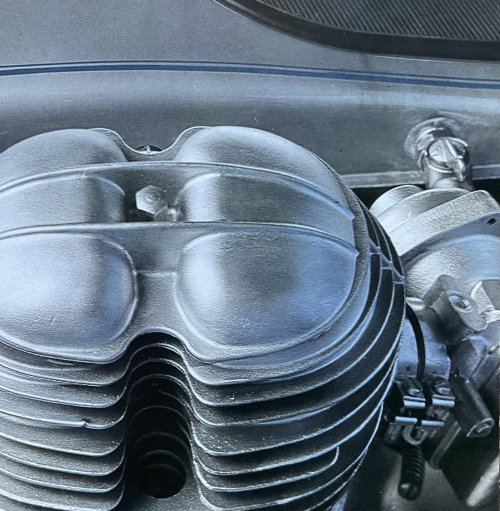

I notice you carb is a 64/32/9 R and mine doesn't have the R. Does that indicate left and right? Mine looks the same as yours.

I have the plugs in the same places that yours' has. The question is, do I want to drill them. I have to say it seems to be a little intimidating. My first thought is to try heat. I read that the varnish that forms in the lines melts at 130 degrees. I'm wondering if I could heat the body and clear the passage with carb cleaner without starting my head on fire.

Now, the question on how to insure the passages from the carb inlet; thru the Idle Mixture Jet; out the micro hole in the floor of the outlet, are clear ? Gotta think on this a bit but, I believe it must be done, backwards ?