greenmachine1100

New member

Good morning,

On the Max BMW site, looking at new parts (my timing problem is in two other threads, so won't repeat)

https://shop.maxbmw.com/fiche/DiagramsMain.aspx?vid=51676&rnd=07242017

It shows the lower alternator pulley as two parts? 04 Rotor, and 05 Pulley?

In the setting the timing thread, I found this from Roger 04 rt:

"As the slotted window still glued to the pulley?" sic, [Is]

Which I took to mean that the inner timing window ring should be 'stuck' to the outer belt pulley. Didn't take 'glue' seriously?

My second clue was in the Chris Harris video on alt. belt replacement. Upon removing the lower pulley, he said roughly paraphrasing, "these pulleys have a tack weld that is known to fail", and he was showing and handling the lower pulley as one part. Inner rotor was 'stuck' to outer pulley. In the Illinois BMW video on topic of replacing and adjusting HES plate he briefly shows his removed lower pulley and it is one part = inner rotor is 'stuck' to outer pulley.

Can anyone tell me why these two sources contradict each other? Is it a two piece part? How is it stuck together?

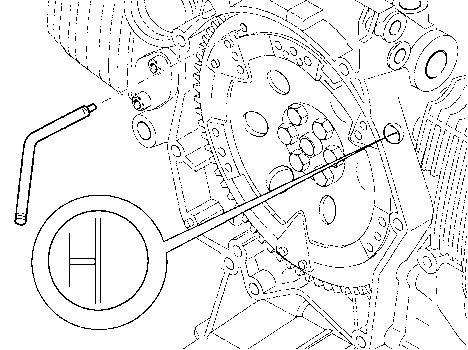

Because I went forward and welded them together:

Haha!

Haha!

I thought it was the source of my ignition problems. Obviously, the inner rotor, with the key hole/tab is the important piece for alignment and timing. Didn't think the outer pulley orientation mattered, but they shouldn't move independently.

On the Max BMW site, looking at new parts (my timing problem is in two other threads, so won't repeat)

https://shop.maxbmw.com/fiche/DiagramsMain.aspx?vid=51676&rnd=07242017

It shows the lower alternator pulley as two parts? 04 Rotor, and 05 Pulley?

In the setting the timing thread, I found this from Roger 04 rt:

"As the slotted window still glued to the pulley?" sic, [Is]

Which I took to mean that the inner timing window ring should be 'stuck' to the outer belt pulley. Didn't take 'glue' seriously?

My second clue was in the Chris Harris video on alt. belt replacement. Upon removing the lower pulley, he said roughly paraphrasing, "these pulleys have a tack weld that is known to fail", and he was showing and handling the lower pulley as one part. Inner rotor was 'stuck' to outer pulley. In the Illinois BMW video on topic of replacing and adjusting HES plate he briefly shows his removed lower pulley and it is one part = inner rotor is 'stuck' to outer pulley.

Can anyone tell me why these two sources contradict each other? Is it a two piece part? How is it stuck together?

Because I went forward and welded them together:

Haha!

Haha!I thought it was the source of my ignition problems. Obviously, the inner rotor, with the key hole/tab is the important piece for alignment and timing. Didn't think the outer pulley orientation mattered, but they shouldn't move independently.