Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mid-South ride, eat, and meet

- Thread starter barryg

- Start date

mikegalbicka

Back in the saddle again

Merry New Year and Happy Christmas.

You are not alone!

You are not alone!

I seem to be having a problem putting my thoughts in proper sequence and context. Must be old timers syndrome.

Polar Bear Ride

Any riders in the Memphis/Mid-South area looking to ride:

January 1, 2024

Group meets at Circle K/Shell Wolfchase 10:00 Depart 10:30

8140 US Highway 64 Bartlett, Tn.

Ride to Shelby Forest General Store 77 Benjestown Rd. , Millington, Tn. 38053

Then on to the boat ramp on the Mississippi River at Meeman-Shelby Forest State Park on the North Road.

Any riders in the Memphis/Mid-South area looking to ride:

January 1, 2024

Group meets at Circle K/Shell Wolfchase 10:00 Depart 10:30

8140 US Highway 64 Bartlett, Tn.

Ride to Shelby Forest General Store 77 Benjestown Rd. , Millington, Tn. 38053

Then on to the boat ramp on the Mississippi River at Meeman-Shelby Forest State Park on the North Road.

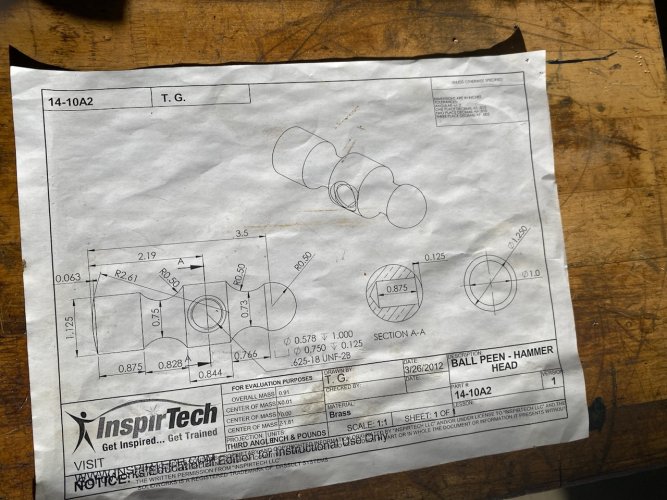

Got back in the machine shop class, working on the Ball Peen Hammer Head. Just finished my rendition.

View attachment 93988

Nice Barry,

What method did you use to make the interior threads?

Thanks.

OM

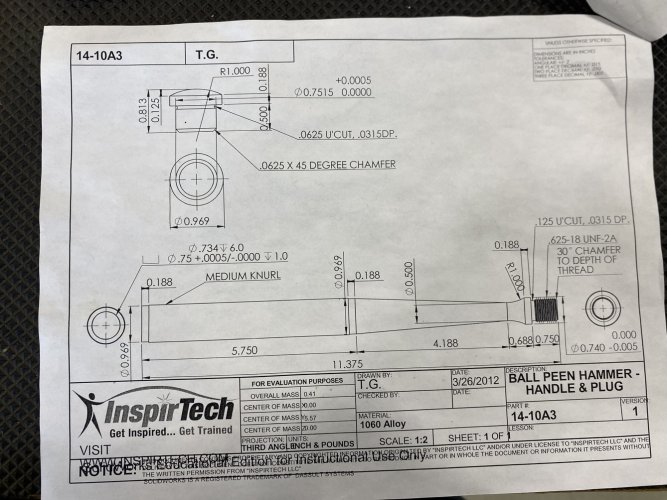

View attachment 93991

Just clamped it to the milling machine table, then center drill, drill and tap.

Thanks!

I didn’t know if you had cut them with the lathe…….which seems possible but tricky. I have used that method before but always turning the quill by hand.

OM

It’s a little tricky, clamp the piece to the table, using the slots to locate the bar. The slots also square the bar to the milling machine. Center the quill over the bar stock. The bar is parallel the the key slot. Find center using either the bar or the slot. Use a center drill to start the hole. Then tap drill the hole. Chuck up the correct size tap. Make sure the quill is not lock down. Lock down the table in both x and y directions.

Turn the quill on slow rpm and pull the quill down to contact the bar. As the quill/tap starts to penetrate the hole, turn off. Unchuck the tap. Finish by using a tap handle to continue the tapping procedure till hole is fully tapped to the bottom of the hole.

Turn the quill on slow rpm and pull the quill down to contact the bar. As the quill/tap starts to penetrate the hole, turn off. Unchuck the tap. Finish by using a tap handle to continue the tapping procedure till hole is fully tapped to the bottom of the hole.

It’s a little tricky, clamp the piece to the table, using the slots to locate the bar. The slots also square the bar to the milling machine. Center the quill over the bar stock. The bar is parallel the the key slot. Find center using either the bar or the slot. Use a center drill to start the hole. Then tap drill the hole. Chuck up the correct size tap. Make sure the quill is not lock down. Lock down the table in both x and y directions.

Turn the quill on slow rpm and pull the quill down to contact the bar. As the quill/tap starts to penetrate the hole, turn off. Unchuck the tap. Finish by using a tap handle to continue the tapping procedure till hole is fully tapped to the bottom of the hole.

Sounds sorta like what I did as far as alignment. It was a smaller hole in brass so I was able to turn the quill by hand. Probably would not have been able to if it was steel. It’s a good way to get things “squared”.

Thanks.

OM