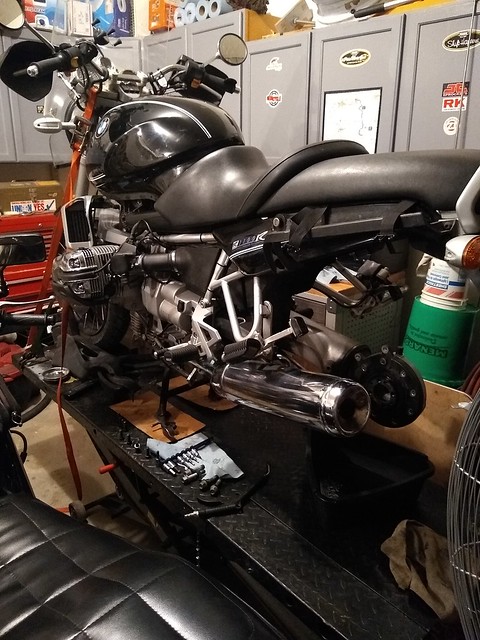

Had a nice 60° day here on Monday so I decided to go for a little ride. 145 miles later and I got back home, parked in the garage and went in the house for a cup of coffee.

Went back out to the garage and found what this collection of photos show. I guess I am lucky to have made it home.

IMG_20230213_165537462 by Larry Alkire, on Flickr

IMG_20230213_165537462 by Larry Alkire, on Flickr

IMG_20230213_165713528 by Larry Alkire, on Flickr

IMG_20230213_165713528 by Larry Alkire, on Flickr

IMG_20230213_165717142 by Larry Alkire, on Flickr

IMG_20230213_165717142 by Larry Alkire, on Flickr

IMG_20230215_153222817 by Larry Alkire, on Flickr

IMG_20230215_153222817 by Larry Alkire, on Flickr

IMG_20230215_153113135 by Larry Alkire, on Flickr

IMG_20230215_153113135 by Larry Alkire, on Flickr

What's next? Is this something that can be reconditioned, or replaced? When I removed the drain plug it had quite a bit of shiny metallic particles on the magnet.

I'm thinking the seal went bad and just let the gear oil out or did a bearing in the FD give up the ghost and go out causing the seal to leak?

Suggestions appreciated as I know this is not the 1st time for this to happen to others.

TIA.

Went back out to the garage and found what this collection of photos show. I guess I am lucky to have made it home.

IMG_20230213_165537462 by Larry Alkire, on Flickr

IMG_20230213_165537462 by Larry Alkire, on Flickr IMG_20230213_165713528 by Larry Alkire, on Flickr

IMG_20230213_165713528 by Larry Alkire, on Flickr IMG_20230213_165717142 by Larry Alkire, on Flickr

IMG_20230213_165717142 by Larry Alkire, on Flickr IMG_20230215_153222817 by Larry Alkire, on Flickr

IMG_20230215_153222817 by Larry Alkire, on Flickr IMG_20230215_153113135 by Larry Alkire, on Flickr

IMG_20230215_153113135 by Larry Alkire, on FlickrWhat's next? Is this something that can be reconditioned, or replaced? When I removed the drain plug it had quite a bit of shiny metallic particles on the magnet.

I'm thinking the seal went bad and just let the gear oil out or did a bearing in the FD give up the ghost and go out causing the seal to leak?

Suggestions appreciated as I know this is not the 1st time for this to happen to others.

TIA.

I thought one of the bike series, maybe the KLT, also had issues with rear bearing failures but the issue was being properly set up with shimming.

I thought one of the bike series, maybe the KLT, also had issues with rear bearing failures but the issue was being properly set up with shimming.