glenfiddich

TravelsWithBarley.com

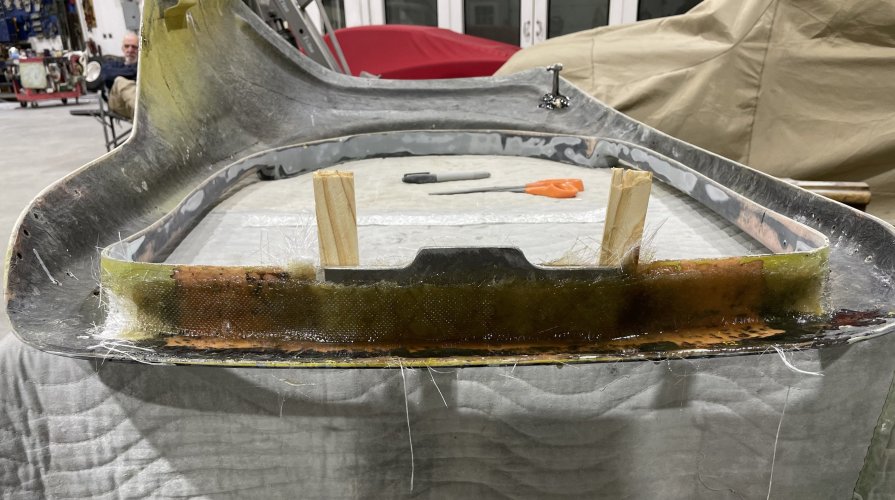

With the fender fully cured I mounted it to the tub so it could be tweaked in situ. First the whiskers came off, then the arc was worked into a uniform curve, and last the body of the fender sanded smooth. Tomorrow I start finessing with filler

Cured fender mounted to the tub for finishing work

Still a flat spot around ten o’clock, but pretty close to as good as it gets before applying body filler

Front: leading edge. Rather than fussing with the gap I decided to go with fender welting after all

Rear: trailing edge

Cured fender mounted to the tub for finishing work

Still a flat spot around ten o’clock, but pretty close to as good as it gets before applying body filler

Front: leading edge. Rather than fussing with the gap I decided to go with fender welting after all

Rear: trailing edge