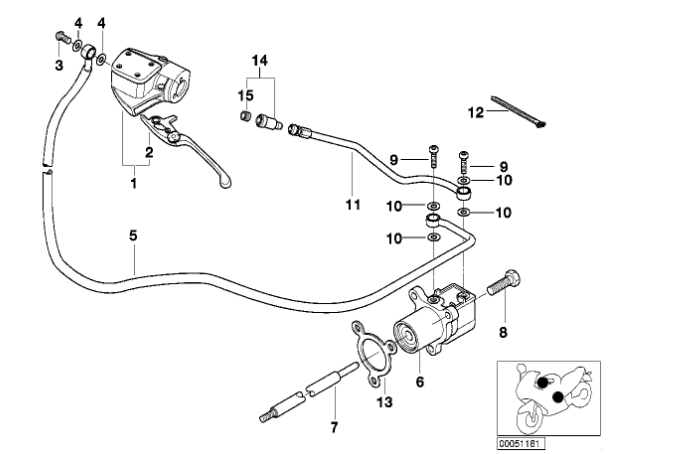

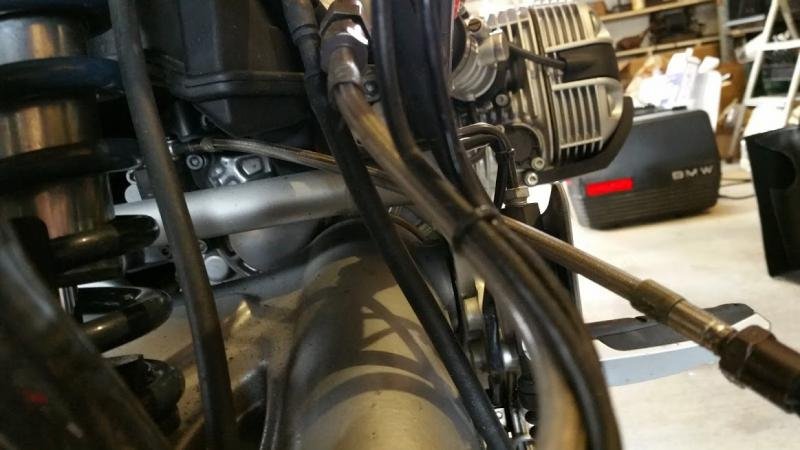

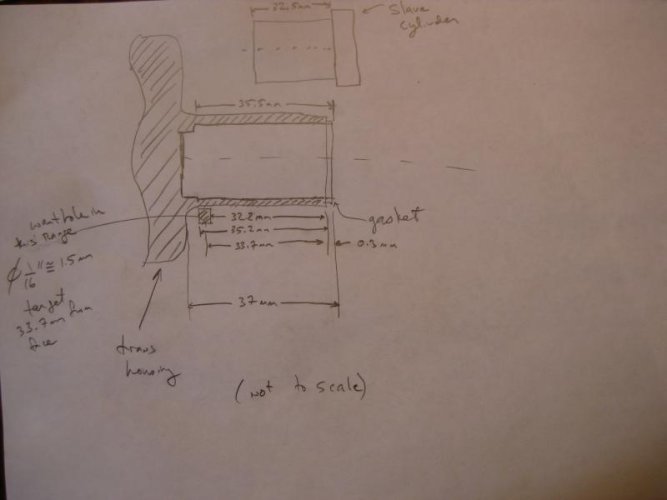

Great forum: I've benefited from the information shared here many times for my bikes, but have not been able to find a direct answer to whether one can get relatively direct access to the hydraulic clutch line attach location on the slave cylinder (in front of the rear shock, beneath the air box).

I replaced the brake lines on the bike with stainless steel versions for preventive reasons, and had hoped to do the same with the clutch line. Not sure if removing the muffler would give enough access, or if one does need to remove the air box to access the banjo bolt (air box removal is bit involved as I understand it). Maybe I could get a tool in to loosen / tighten the bolt without removing anything else, but doubt I would be able to even get the bolt to start threading to reattach.

For reference, I have been reading this thread http://advwisdom.hogranch.com/Wisdom/Clutch Flush.php.html

Any thoughts out there?

I replaced the brake lines on the bike with stainless steel versions for preventive reasons, and had hoped to do the same with the clutch line. Not sure if removing the muffler would give enough access, or if one does need to remove the air box to access the banjo bolt (air box removal is bit involved as I understand it). Maybe I could get a tool in to loosen / tighten the bolt without removing anything else, but doubt I would be able to even get the bolt to start threading to reattach.

For reference, I have been reading this thread http://advwisdom.hogranch.com/Wisdom/Clutch Flush.php.html

Any thoughts out there?