sonny_p

New member

Hey, everybody! Looking for some sage wisdom to help with a mysterious blowing fuse that I have on my 1978 BMW R100/7.

Here’s the full story:

Went on a ride two weeks ago and somewhere along the way lost several electrical systems at once: all 4 turn signal lights, brake light, turn signal indicator light and buzzer, and voltmeter. Quick google told me that these systems are on the same 8A fuse in the headlight bucket wiring assembly. Went to explore inside the headlight bucket and discovered the fuse had in fact blown. I had six spare 8A ceramic fuses from a local BMW Motorad shop, and threw a new one in. Turned the ignition on, and the fuse did NOT blow. Watched the fuse as I tested turn signals and brake light. All systems seemed normal. My first thought was that I couldn’t have a short, or else the fuse would have blown immediately with the ignition turned on, right? I waited and watched and kept testing systems and the fuse seemed happy, so threw the headlight back on and went to ride again. Sure enough, only took 50 yards for the fuse to blow. Now I began to wonder if maybe the shaking of the engine pinched a cable to cause a short that I couldn’t locate with the bike sitting still. Went back behind the headlight and came to the forum to see if others had seen this before. A few folks seemed to have similar symptoms that were caused by a faulty turn signal relay. I pulled out my multimeter and tested resistance across each prong of the relay to make sure I didn’t have an internal short inside. Resistance tested normal, so I went to test voltage. The relay was getting a normal 12V’s of power. And with a new fuse in place, the appropriate relay prongs for the turn signals flashed 12V intermittently with the lights. It seems that the voltage and resistance across the relay is normal. Testing each of the systems again, the new fuse did not blow. I figured it must be some sort of draw that only happened when the engine was on (which was wrong). Fired up the engine and had a friend peek inside the headlight bucket. All systems still worked normally! BUT THEN I tried something new—front brake lever AND turn signal. The fuse blew. Well, that explains why the first time I tried to fix it I only made it 50 yards—that’s the first time I first squeezed the brake and put on my turn signal!

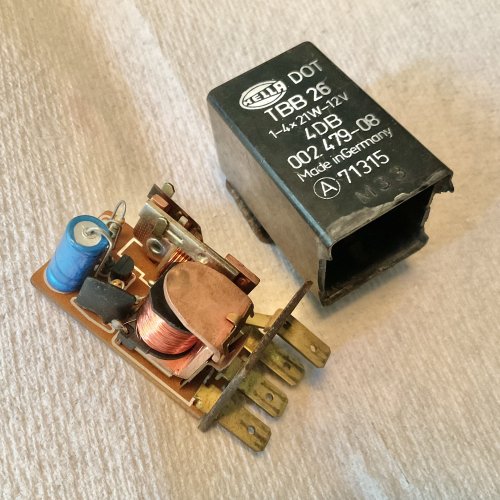

So that’s the long exposition. Here’s the TLDR—after two blown fuses, I’ve figured out that the combined current draw of my brake light and turn signal lights is greater than 8A. The bike seems pretty damn stock to me (though I’ll readily admit to being a newbie airhead!) so I don’t think that’s the issue. There are maaayyybe one or two electrical parts in the headlight bucket that seem aftermarket. But before this issue, the bike worked normally for thousands of miles. No recent new changes. Included a pic below of my headlight electrical assembly.

Thanks for the help brainstorming on this one!

Here’s the full story:

Went on a ride two weeks ago and somewhere along the way lost several electrical systems at once: all 4 turn signal lights, brake light, turn signal indicator light and buzzer, and voltmeter. Quick google told me that these systems are on the same 8A fuse in the headlight bucket wiring assembly. Went to explore inside the headlight bucket and discovered the fuse had in fact blown. I had six spare 8A ceramic fuses from a local BMW Motorad shop, and threw a new one in. Turned the ignition on, and the fuse did NOT blow. Watched the fuse as I tested turn signals and brake light. All systems seemed normal. My first thought was that I couldn’t have a short, or else the fuse would have blown immediately with the ignition turned on, right? I waited and watched and kept testing systems and the fuse seemed happy, so threw the headlight back on and went to ride again. Sure enough, only took 50 yards for the fuse to blow. Now I began to wonder if maybe the shaking of the engine pinched a cable to cause a short that I couldn’t locate with the bike sitting still. Went back behind the headlight and came to the forum to see if others had seen this before. A few folks seemed to have similar symptoms that were caused by a faulty turn signal relay. I pulled out my multimeter and tested resistance across each prong of the relay to make sure I didn’t have an internal short inside. Resistance tested normal, so I went to test voltage. The relay was getting a normal 12V’s of power. And with a new fuse in place, the appropriate relay prongs for the turn signals flashed 12V intermittently with the lights. It seems that the voltage and resistance across the relay is normal. Testing each of the systems again, the new fuse did not blow. I figured it must be some sort of draw that only happened when the engine was on (which was wrong). Fired up the engine and had a friend peek inside the headlight bucket. All systems still worked normally! BUT THEN I tried something new—front brake lever AND turn signal. The fuse blew. Well, that explains why the first time I tried to fix it I only made it 50 yards—that’s the first time I first squeezed the brake and put on my turn signal!

So that’s the long exposition. Here’s the TLDR—after two blown fuses, I’ve figured out that the combined current draw of my brake light and turn signal lights is greater than 8A. The bike seems pretty damn stock to me (though I’ll readily admit to being a newbie airhead!) so I don’t think that’s the issue. There are maaayyybe one or two electrical parts in the headlight bucket that seem aftermarket. But before this issue, the bike worked normally for thousands of miles. No recent new changes. Included a pic below of my headlight electrical assembly.

Thanks for the help brainstorming on this one!