justabill

Member

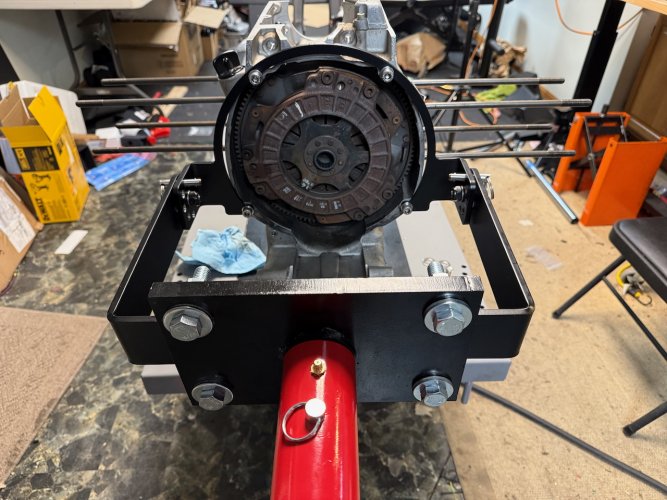

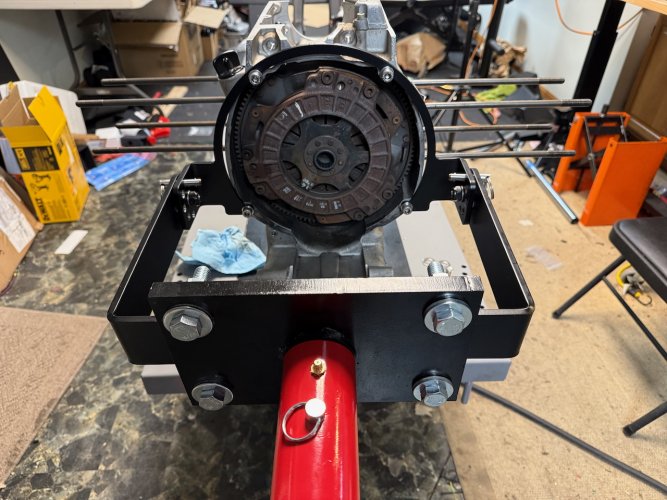

Ok, designed may be an overstatement. I looked at a lot of designs, then made about a dozen variations in software to arrive at this one. I had the metal cut and bent by SendCutSend and spent too much on hardware, but I am happy with the result. It can be bolted to an appropriately strong bench or onto your standard Harbor Freight motor stand.

I figured that this would come in handy since that motor is my second rebuild and I took delivery of a 3rd airhead today. My hobby is becoming a lot more than a hobby.

I figured that this would come in handy since that motor is my second rebuild and I took delivery of a 3rd airhead today. My hobby is becoming a lot more than a hobby.

Last edited: