sundance71

New member

Hi Folks,

I am doing my first TB synch on my 04 R1150RT today and I was having some difficulty getting the sides balanced. I've done this on other bikes but this is my first time on the RT. Before I get too far in the weeds about what is going on, here is the current state of the bike.

12000 Miles

Good compression both sides

New plugs

Valves adjusted

New air filter

New fuel filter, internal tank lines, screen, cleaned vent holes, etc.

Balanced R1200 injectors from Tills

Throttle bodies removed and thoroughly cleaned. I did not move the idle stop screws or the TPS sensor from the positions that they were in when I got the bike.

New BBS's

AFXIED from BeemerBoneyard installed and set to 7

Aftermarket Delkevic slip on pipe. (looks and sounds awesome)

Motronic and TPS reset this morning

The bike starts right up and idles ok, but when I go to do the sync, I cannot get better agreement between the two sides than about 20-25 mm HG at idle as shown in the pic.

The BBS's are only turned out maybe .5-.75 turns to get around an 1100RPM idle. I think that most folks were reporting about 2-2.5 turns.

The TPS voltage with the butterflies on the stops (I checked) was about 425 mV from the white/red wire to the negative on the battery.

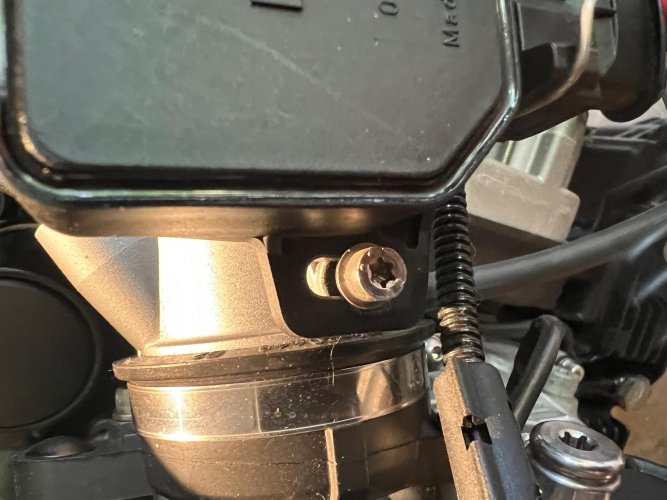

The factory paint on the throttle stop screws looks to be intact as best as I can see.

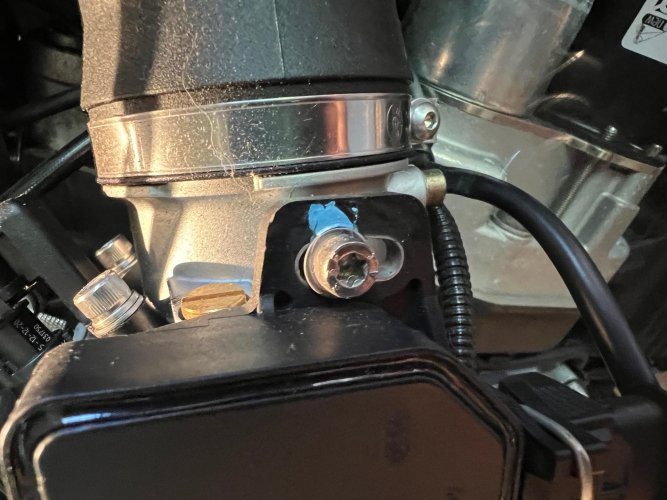

I'm not sure about the TPS sensor. There is paint on one side but most of it is missing from the other screw. (see pics)

Anyway, my question is; Based on what I've described, does it sound as though the TPS and or the throttle stop screws were adjusted by the previous owner?

I've read through Roger's procedure for resetting this and I'm good doing it. I just wanted to get a second opinion before I start tinkering with things.

Thanks

Chris

I am doing my first TB synch on my 04 R1150RT today and I was having some difficulty getting the sides balanced. I've done this on other bikes but this is my first time on the RT. Before I get too far in the weeds about what is going on, here is the current state of the bike.

12000 Miles

Good compression both sides

New plugs

Valves adjusted

New air filter

New fuel filter, internal tank lines, screen, cleaned vent holes, etc.

Balanced R1200 injectors from Tills

Throttle bodies removed and thoroughly cleaned. I did not move the idle stop screws or the TPS sensor from the positions that they were in when I got the bike.

New BBS's

AFXIED from BeemerBoneyard installed and set to 7

Aftermarket Delkevic slip on pipe. (looks and sounds awesome)

Motronic and TPS reset this morning

The bike starts right up and idles ok, but when I go to do the sync, I cannot get better agreement between the two sides than about 20-25 mm HG at idle as shown in the pic.

The BBS's are only turned out maybe .5-.75 turns to get around an 1100RPM idle. I think that most folks were reporting about 2-2.5 turns.

The TPS voltage with the butterflies on the stops (I checked) was about 425 mV from the white/red wire to the negative on the battery.

The factory paint on the throttle stop screws looks to be intact as best as I can see.

I'm not sure about the TPS sensor. There is paint on one side but most of it is missing from the other screw. (see pics)

Anyway, my question is; Based on what I've described, does it sound as though the TPS and or the throttle stop screws were adjusted by the previous owner?

I've read through Roger's procedure for resetting this and I'm good doing it. I just wanted to get a second opinion before I start tinkering with things.

Thanks

Chris