highlandboy

New member

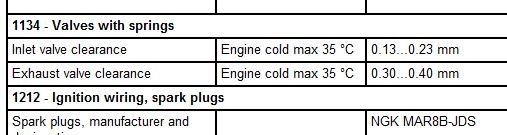

29,000 Kilometres on bike. Checking valve adjustment. I found all the exhaust between 30to35mm and on the intake 15to18mm. My Haynes manual calls for 40-66 on exhaust and 23-43 on the intake. The bike run powerfully and quiet. I found a Youtube video that says my bike is within spec and many comments on the forum that says I should not need to do an adjustment at this low milage. What is the correct info?