Snowflake wheels

Right after I bought the '78 R100Rs for a restoration, I also bought an '83 R100/T. The R100/T was somewhat of a basket case, and the rear Snowflake wheel had been removed --- the wheel bearing had seized.

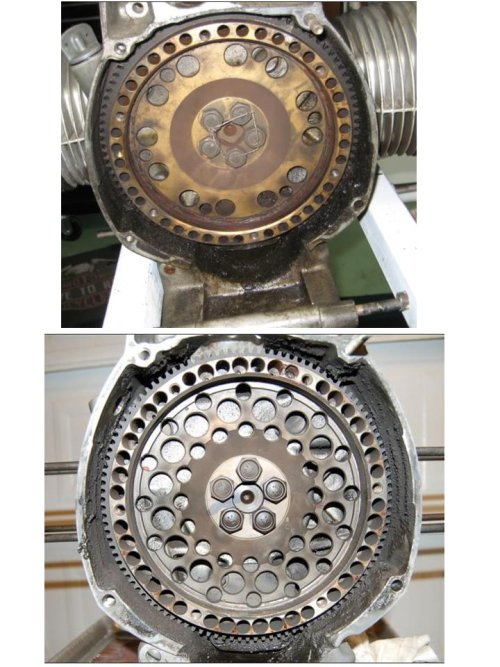

I have the Snowflakes cleaned, powdercoated, and I plan to install them on the '78 R100RS. I have pressed in the bearing races in both wheels and installed the distance spacers with the plastic donuts. Hopefully I can figure out the wedding band spacers and the top-hat spacers.

Look at the picture of the Rear Drum Snowflake. The bearing race presses deep into the hub on that side of the wheel. The distance to the edge is much more than the thickness of the oil seal. Am I to assume that the seal installs flush to the edge of the hub?

I think there is an 18.7mm bushing that installs on that side of the axle. Right?

I did not get to observe how everything fits since the wheel was already disassembled.

Right after I bought the '78 R100Rs for a restoration, I also bought an '83 R100/T. The R100/T was somewhat of a basket case, and the rear Snowflake wheel had been removed --- the wheel bearing had seized.

I have the Snowflakes cleaned, powdercoated, and I plan to install them on the '78 R100RS. I have pressed in the bearing races in both wheels and installed the distance spacers with the plastic donuts. Hopefully I can figure out the wedding band spacers and the top-hat spacers.

Look at the picture of the Rear Drum Snowflake. The bearing race presses deep into the hub on that side of the wheel. The distance to the edge is much more than the thickness of the oil seal. Am I to assume that the seal installs flush to the edge of the hub?

I think there is an 18.7mm bushing that installs on that side of the axle. Right?

I did not get to observe how everything fits since the wheel was already disassembled.