R

rbleau

Guest

Progress report 3-6-09

OK, Greetings, fellow motorcycle persons of the BMW persuasion. Big day today.

Parts & Materials: my Kroil came yesterday evening by FEDEX at 6:54 CDT (dark), so I had a pleasant ritual this morning shooting Kroil into the cylinders and about whatever else I could think of, strolling about in my jammies, sipping coffee and blasting away.

Administrative accomplishment: this RS was a Bill of sale purchase; I did the bureaucracy dance, at three Govt offices, roughly each separated by 40 miles, and as of 1600 CDT I had successfully navigated the local Auto registration, the Regional auto reg over in Arlington, TX (Six Flags traffic on a Friday) and the County courthouse, obtained a hearing and I am now the legal title holder and owner of record. Lucky day, no doubt.

Tech notes: Regarding how to unstick a potentially frozen motor, I have read much, and today I thoroughly examined a completely torn down motor and talked with an authoritative source I have found to be reliable. I certainly welcome comments on these topics.

(a) Overfilling idea: the cam is below the crank, and there is a casting, a wall in there. Highly doubtful if the overfill would accomplish the desired result.

(b) Drop pan and spray lube on main bearings - no go, no access.

(c) Push oil into the oil filter exit passageway: unlikely, as it would not get past the oil pump

(d) Turn motor using the allen bolt on the front of the crank - bad move, it lacks the strength and could snap, which would be expensive; better to put in gear and "bump it" using rear wheel, as those components are built to withstand the torque forces of riding the machine.

Today's actual physical progress: With proof of ownership in hand, and the decks cleared, shop rearranged, got under the RS ("her" or "she"), and removed the trans drain plug. Being 60, arthritic and all and not wishing to make too big an event, I just started out with a nice length of pipe extending my Craftsman socket wrench. The drain plug really was not as tight as I expected.

The horror ! I may have made an audible sound of agony - only a few drops of what looked like water came out into the catch pan...wait a few seconds, maybe a couple more drops. Oh oh. This is not good.

Oh well, cleaned the drain plug as something to do while pondering what appeared to be an empty transmission with just a few drops of water in it. Oh well.

I then removed the fill plug for the trans. Huh? oil gushed out ! HUH ???? big stupid look on my face.

Got under her, and shot some pen oil up into the drain hole and a GUSHER occurred with a small amount of water and goodly quantity of oil ~! Wow ~! Like in the movies of the early days of oil exploration - a gusher !

Theory: my theory is that some water settled to the bottom of the transmission and over 20 years formed a "seal" (waxy/clay-like perhaps) which formed a dam or "plug" that broke when I shot the pen oil up there.

My wishful thinking: am hoping the trans is not too heavily damaged, hopefully the water was not high enough to get into importnt parts, and you know - the trans oil really was not very dirty - surprising.

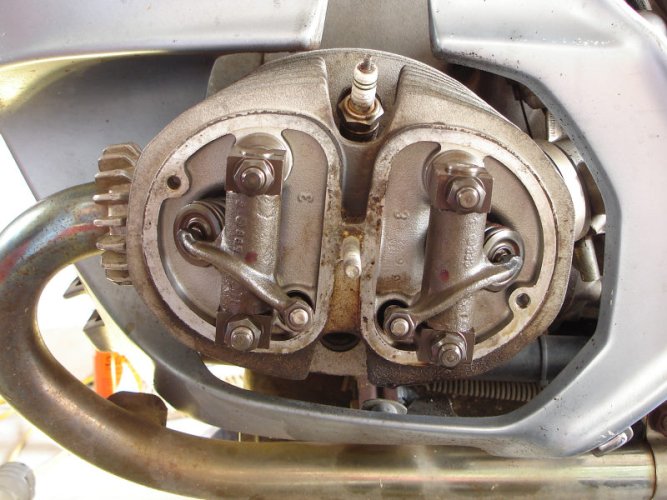

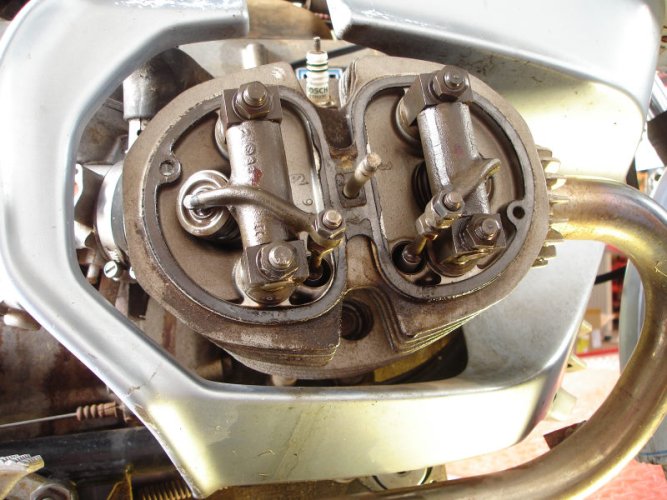

Today's photo: rearranged shop. the R100S on the lift is getting some right (starboard) caliper work done.

Regards / Ron

OK, Greetings, fellow motorcycle persons of the BMW persuasion. Big day today.

Parts & Materials: my Kroil came yesterday evening by FEDEX at 6:54 CDT (dark), so I had a pleasant ritual this morning shooting Kroil into the cylinders and about whatever else I could think of, strolling about in my jammies, sipping coffee and blasting away.

Administrative accomplishment: this RS was a Bill of sale purchase; I did the bureaucracy dance, at three Govt offices, roughly each separated by 40 miles, and as of 1600 CDT I had successfully navigated the local Auto registration, the Regional auto reg over in Arlington, TX (Six Flags traffic on a Friday) and the County courthouse, obtained a hearing and I am now the legal title holder and owner of record. Lucky day, no doubt.

Tech notes: Regarding how to unstick a potentially frozen motor, I have read much, and today I thoroughly examined a completely torn down motor and talked with an authoritative source I have found to be reliable. I certainly welcome comments on these topics.

(a) Overfilling idea: the cam is below the crank, and there is a casting, a wall in there. Highly doubtful if the overfill would accomplish the desired result.

(b) Drop pan and spray lube on main bearings - no go, no access.

(c) Push oil into the oil filter exit passageway: unlikely, as it would not get past the oil pump

(d) Turn motor using the allen bolt on the front of the crank - bad move, it lacks the strength and could snap, which would be expensive; better to put in gear and "bump it" using rear wheel, as those components are built to withstand the torque forces of riding the machine.

Today's actual physical progress: With proof of ownership in hand, and the decks cleared, shop rearranged, got under the RS ("her" or "she"), and removed the trans drain plug. Being 60, arthritic and all and not wishing to make too big an event, I just started out with a nice length of pipe extending my Craftsman socket wrench. The drain plug really was not as tight as I expected.

The horror ! I may have made an audible sound of agony - only a few drops of what looked like water came out into the catch pan...wait a few seconds, maybe a couple more drops. Oh oh. This is not good.

Oh well, cleaned the drain plug as something to do while pondering what appeared to be an empty transmission with just a few drops of water in it. Oh well.

I then removed the fill plug for the trans. Huh? oil gushed out ! HUH ???? big stupid look on my face.

Got under her, and shot some pen oil up into the drain hole and a GUSHER occurred with a small amount of water and goodly quantity of oil ~! Wow ~! Like in the movies of the early days of oil exploration - a gusher !

Theory: my theory is that some water settled to the bottom of the transmission and over 20 years formed a "seal" (waxy/clay-like perhaps) which formed a dam or "plug" that broke when I shot the pen oil up there.

My wishful thinking: am hoping the trans is not too heavily damaged, hopefully the water was not high enough to get into importnt parts, and you know - the trans oil really was not very dirty - surprising.

Today's photo: rearranged shop. the R100S on the lift is getting some right (starboard) caliper work done.

Regards / Ron

Attachments

Last edited: