gtgt_bangbang

New member

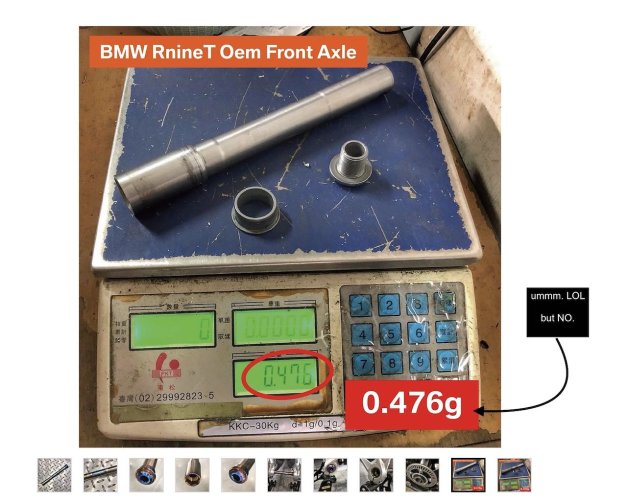

A titanium front axle may be a decent add; could shed quite a bit of unsprung weight at a good spot.

seems easy enough part to fab,

theres a 20mm stock diameter of grade 5 round for $35 on the bay,

Then just needs turned down to 17 & threaded.

I dont have a machine shop in mind but I rather call around asking them to make a couple few , than a one off.

Any of you axholes want one ?

seems easy enough part to fab,

theres a 20mm stock diameter of grade 5 round for $35 on the bay,

Then just needs turned down to 17 & threaded.

I dont have a machine shop in mind but I rather call around asking them to make a couple few , than a one off.

Any of you axholes want one ?