Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spline Evaluation Request... (93 K75S)

- Thread starter jfriedman149

- Start date

jfriedman149

New member

pglaves

#13338

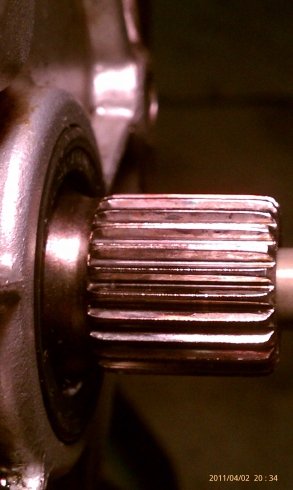

The clutch hub splines look good to me. The shaft splines appear to show some wear but it is hard to tell how much of a notch is there. An almost end view would tell me more.

If these parts came out of the same bike my guess is that is not the original clutch hub that mated with that shaft but as I said, from the picture of the shaft I can't draw hard conclusions.

If these parts came out of the same bike my guess is that is not the original clutch hub that mated with that shaft but as I said, from the picture of the shaft I can't draw hard conclusions.

jfriedman149

New member

jfriedman149

New member

The clutch hub splines look good to me. The shaft splines appear to show some wear but it is hard to tell how much of a notch is there. An almost end view would tell me more.

If these parts came out of the same bike my guess is that is not the original clutch hub that mated with that shaft but as I said, from the picture of the shaft I can't draw hard conclusions.

They did come out of the same bike - dry splines after only 6-7K miles. The shaft was "new to me" from a friend, as I had burned up my original one, along with the clutch hub. The bike has needed spline lubrication every 4-7K miles (lubricant depending) since I bought it. It had a new clutch disc put in when I first got it, as the one in the bike was toast from the previous owner slipping the clutch, and never having done a spline lube since he bought it (5-6 years previous to my acquiring it).

I'm at the (almost) inescapable conclusion that I have the dreaded "Intermediate Housing" issue.

I'll find the original shaft (gotta dig through the boxes of "stuff") and take a picture of the removed/dead one.

I have another intermediate housing on the way, along with new bearings, seals, and locator pins.

The principal question is: should I replace the input shaft now, or simply take slightly shorter clutch disc life for a disc or two now, then replace it when its well and truly gone - assuming that I can cure the misalignment / short spline lube life issue with a new intermediate housing.

Input shaft is shot. See the taper in the tops of the teeth front to back. It will only wear out good discs (which yours appears to be) at an accelerated rate.

Is the intermediate housing still attached to the engine? If it is, bolt the clutch housing (just the 1st piece, the one you would consider to be the flywheel) back onto the engine.

Take an accurate straight edge and lay it across the transmission mounting surface of the intermediate housing. Take a depth micrometer and measure the distances to a machined surface on the clutch housing as close to the outer diameter of it as possible. Take several measurements (top, bottom, left and right) and next to all bolt holes and locating pins. This SHOULD tell you if the intermediate housing is off (which it sounds like it is) and give you a little more piece of mind if your new one is better.

Is the intermediate housing still attached to the engine? If it is, bolt the clutch housing (just the 1st piece, the one you would consider to be the flywheel) back onto the engine.

Take an accurate straight edge and lay it across the transmission mounting surface of the intermediate housing. Take a depth micrometer and measure the distances to a machined surface on the clutch housing as close to the outer diameter of it as possible. Take several measurements (top, bottom, left and right) and next to all bolt holes and locating pins. This SHOULD tell you if the intermediate housing is off (which it sounds like it is) and give you a little more piece of mind if your new one is better.

Last edited:

jfriedman149

New member

pglaves

#13338

Given the angular wear on the input shaft, and the fact that it went dry in too short a number of miles I would bet that there is an angular misalignment between the centerline of the transmission shaft and the engine output shaft. This was a serious quirk for a number of K75s.

There are at least three reasonable theories for the cause(s) and in fact it could be that all three causes have existed on different bikes.

1. Bent or deformed auxiliary case (bellhousing)

2. Machining out of tolerance in the auxiliary case

3. Improperly applied sealant beads between the auxiliary case and the engine main case.

In almost all cases the removal and maybe replacement of the auxiliary case cures the problem. Some folks found uneven sealant (thick beads instead of very thin smears) as if they waited too long after applying the sealant to bolt stuff together. This causes the auxiliary case to bolt up crooked on the main engine case. That misaligns the transmission.

So - the fix is to remove the auxiliary case (bellhousing) from the engine. If there is a detectable and obvious bead of sealant that doesn't look like a thin smear that could be the problem and I would be tempted to simply put it back on right.

If not, then it is probably a bent, warped, or mismachined auxiliary case and the fix will be to find another and put it on. Try to find a used one (it is not a wear part) from a high mileage bike. If one is bent or warped or defective they don't make it to high mileage before owners give up on the things.

There are at least three reasonable theories for the cause(s) and in fact it could be that all three causes have existed on different bikes.

1. Bent or deformed auxiliary case (bellhousing)

2. Machining out of tolerance in the auxiliary case

3. Improperly applied sealant beads between the auxiliary case and the engine main case.

In almost all cases the removal and maybe replacement of the auxiliary case cures the problem. Some folks found uneven sealant (thick beads instead of very thin smears) as if they waited too long after applying the sealant to bolt stuff together. This causes the auxiliary case to bolt up crooked on the main engine case. That misaligns the transmission.

So - the fix is to remove the auxiliary case (bellhousing) from the engine. If there is a detectable and obvious bead of sealant that doesn't look like a thin smear that could be the problem and I would be tempted to simply put it back on right.

If not, then it is probably a bent, warped, or mismachined auxiliary case and the fix will be to find another and put it on. Try to find a used one (it is not a wear part) from a high mileage bike. If one is bent or warped or defective they don't make it to high mileage before owners give up on the things.

jfriedman149

New member

I already have another intermediate housing on the way, along with other supporting parts (new sprag bearing and seal, locator pins - just in case, clutch bolts/washers, flywheel nut & o-ring, etc.).

I'll poke and prod more next weekend, and I'll let y'all know what I found RE: sealant around the housing, etc.

Thanks!

I'll poke and prod more next weekend, and I'll let y'all know what I found RE: sealant around the housing, etc.

Thanks!

jfriedman149

New member

Try and measure it before you disassemble it. It might tell you something. Then remeasure after you reassemble with what ever parts you choose.

I have a friend who is a mechanical engineer. I'm going to ask him to measure and see what he finds. He has nice measuring toys from Starrett, Mitutoyo, and such...

jfriedman149

New member

After much consideration, and attempts at getting repeatable measurements, it was my and my friend's conclusion that without a portable CMM, taking the measurements with a simple depth micrometer was for the most part meaningless, given the lack of repeatability.

I've gone ahead and swapped in a new intermediate housing and flywheel (set, same bike) from a known good K75 that was parted out for various other reasons (electrical, or so I was told).

I'll posting some of the pictures I took during the reassembly as an FYI to those that are curious as to what the "insides" look like.

I'll know more in about 4-7K miles - either I'll need to do another spline lube (i.e. the issue is not resolved - the clutch starts not releasing again) or the bike will be just fine.

Thanks again for all your help and guidance!

I've gone ahead and swapped in a new intermediate housing and flywheel (set, same bike) from a known good K75 that was parted out for various other reasons (electrical, or so I was told).

I'll posting some of the pictures I took during the reassembly as an FYI to those that are curious as to what the "insides" look like.

I'll know more in about 4-7K miles - either I'll need to do another spline lube (i.e. the issue is not resolved - the clutch starts not releasing again) or the bike will be just fine.

Thanks again for all your help and guidance!

Attachments

jfriedman149

New member

jfriedman149

New member

jfriedman149

New member

jfriedman149

New member

jfriedman149

New member

I just wonder, how does one measure from one rigidly mounted machined steel surface to another rigidly mounted machined aluminum surface with a depth mike and NOT get repeatable numbers????

Oh yeah, I forgot, you said he was an engineer.

But I AM curious why you couldn't get the numbers to repeat.

You weren't moving or rotating the flywheel were you??

Oh yeah, I forgot, you said he was an engineer.

But I AM curious why you couldn't get the numbers to repeat.

You weren't moving or rotating the flywheel were you??

jfriedman149

New member

... Oh yeah, I forgot, you said he was an engineer....

Yeah, he are an en-gin-eer. One with about a dozen patents on microwave measurement technology to his name.

The essence of it was I didn't have a parallel set that would span the housing and all other attempts at measuring with various and assorted homemade jigs gave me inconsistent numbers - especially when you rotated the flywheel, as there's no real way to tell if the housing surfaces are parallel to the rotating surface of the flywheel (i.e. that there wasn't a warp to the flywheel that presented parallel planes at a given rotational angle). Even so, there's then no real way to tell (assuming that both planes are parallel) that there still isn't axial, in-line displacement (i.e. not angular displacement - the planes not being parallel, but the clutch hub / input shaft being nominally, rotationally centered to each other).

I am, when time and money permits, taking the old flywheel and housing to machine shop with a stationary CMM and have them model/measure the parts to know a little about what I took out.

The 'hero kit' of parts turned out to be the easiest/quickest/cheapest fix for this.

The biggest 'clue' that something was better was on reassembly. The transmission went on to the new intermediate housing without the normal 'colorful language' needed, and in about half the time and gyrations/wiggling it normally took. Its also always been a fight to get the transmission / frame bolts to align and start. After replacing the intermediate housing, they practically self-aligned on bike reassembly (i.e. I could spin them in by hand).

As said (by the aforementioned engineer) "... We'll know more later..."

Similar threads

- Replies

- 1

- Views

- 2K

- Replies

- 1

- Views

- 2K

- Replies

- 15

- Views

- 9K