blacque jacque shellacque

Member

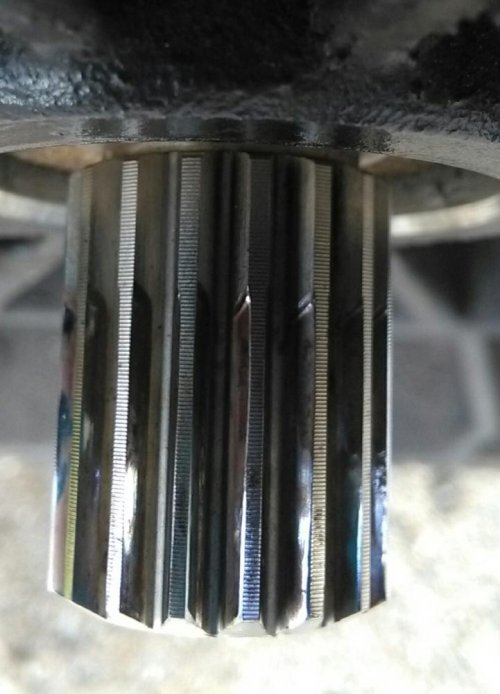

Like all threads at this point in time, the 1150 clutch spline issue has been beaten over and over, but it never really dies. In that light I thought some would enjoy my observations that I gathered from my own experience. Back in 2013 I decided it was time to have a look at the splines on my R1150RS. Mileage at the time was 117K km. (72700 miles) After I removed the transmission and clutch, I took some pictures. The splines on the tranny input shaft showed the classic wear that many have seen on the 1150 series. The splines wear with a tapper closest to the gearbox housing. This can be seen clearly in the photos.

I guesstimated the wear at approximately 15 to 20%. On the other hand the mating clutch splines faired far worse. I would guess that wear was closer to 50%.

Naturally I was dismayed and wondered what I could do, if anything. Others, in numerous threads, and professionals like Anton suggested that a defective or warped clutch carrier was the culprit. With that in mind, I waited for the wife to leave the house. Then using the marble kitchen table as a base, I used a dial gauge to check the carrier for any runout. As far as I could measure, it was quite true. I could find no high or low spots. What I did notice was that the three mating surfaces of the carrier were flat. In the area where the three straps for the clutch pressure plate mount, there was no indentation. The straps are .0035 inch thick, not much. But when I placed the pressure plate and clutch cover together on the clutch carrier naturally there was a .0035 inch gap. When bolting the three parts together, the gap disappeared. I may not be the sharpest knife in the drawer, but it seemed to me that for the gap to go away, something must be warping. I suspected this was not a good thing, and perhaps it could be the source of the strange tapered wear seen on the input shaft. I decided to file materiel from the carrier to create a gap for the .0035 pressure plate straps. I ensured that when buttoned down, there would still be sufficient pressure on the straps and they would have no space to wiggle around in that gap. Now I know that engineers and perfectionists would object to installing a new part with a spline like a disk on a shaft that is worn. I have no doubt that it is an awful and terrible thing to do, but fortunately I am not an engineer, so I had no qualms and went ahead anyway. Ignorance is bliss. I then reassembled using new parts, clutch pressure plate, clutch cover, spring, and Siebenrock disk on the old carrier and worn input shaft.

Now that the 2017 riding season is over, once again I started to worry about those dam splines. I have ridden an additional 85k km, (52000 miles) since the new parts were installed. The input shaft is original and has spun around inside of two clutch disks now for 200200 km. What was going on in there? I went as far as taking a video of the clutch disk play after removing the starter. About 1/8th of an inch, not exactly scientific. That didn’t help. I finally caved in and decided I had to look. Part two to follow.

I guesstimated the wear at approximately 15 to 20%. On the other hand the mating clutch splines faired far worse. I would guess that wear was closer to 50%.

Naturally I was dismayed and wondered what I could do, if anything. Others, in numerous threads, and professionals like Anton suggested that a defective or warped clutch carrier was the culprit. With that in mind, I waited for the wife to leave the house. Then using the marble kitchen table as a base, I used a dial gauge to check the carrier for any runout. As far as I could measure, it was quite true. I could find no high or low spots. What I did notice was that the three mating surfaces of the carrier were flat. In the area where the three straps for the clutch pressure plate mount, there was no indentation. The straps are .0035 inch thick, not much. But when I placed the pressure plate and clutch cover together on the clutch carrier naturally there was a .0035 inch gap. When bolting the three parts together, the gap disappeared. I may not be the sharpest knife in the drawer, but it seemed to me that for the gap to go away, something must be warping. I suspected this was not a good thing, and perhaps it could be the source of the strange tapered wear seen on the input shaft. I decided to file materiel from the carrier to create a gap for the .0035 pressure plate straps. I ensured that when buttoned down, there would still be sufficient pressure on the straps and they would have no space to wiggle around in that gap. Now I know that engineers and perfectionists would object to installing a new part with a spline like a disk on a shaft that is worn. I have no doubt that it is an awful and terrible thing to do, but fortunately I am not an engineer, so I had no qualms and went ahead anyway. Ignorance is bliss. I then reassembled using new parts, clutch pressure plate, clutch cover, spring, and Siebenrock disk on the old carrier and worn input shaft.

Now that the 2017 riding season is over, once again I started to worry about those dam splines. I have ridden an additional 85k km, (52000 miles) since the new parts were installed. The input shaft is original and has spun around inside of two clutch disks now for 200200 km. What was going on in there? I went as far as taking a video of the clutch disk play after removing the starter. About 1/8th of an inch, not exactly scientific. That didn’t help. I finally caved in and decided I had to look. Part two to follow.