blueridgespeed

New member

I rung off one of the torx-head capscrews on the side case mount. These stainless capscrews thread into a sturdy anodized aluminum block.

First it broke off leaving a protruding remnant. I gave it another week of soaking with Kroil (this penetrant has worked for me when others did not)

I made a "coupler" with a nut and threaded the two pieces back together and reworded them. I was glad to have the whole unit easy to work with!

The bolt rung off again, this time flush.

Argh. Plan B - centerpunch and start drilling Pretty easy securing the unit in a drill press vise versus by hand as if often the only option.

After committing to through-drilling the whole thing and either re-tapping or going to a "heli-coil" type thread repair insert - I was on step 3 of slightly larger bits when I broke the bit! Perfectly flush and I can't get it out.

I don't think I'll have any success flailing on this further.

I'm prepared to make a bracket (out of steel) but would like to find one for sale new or used if possible.

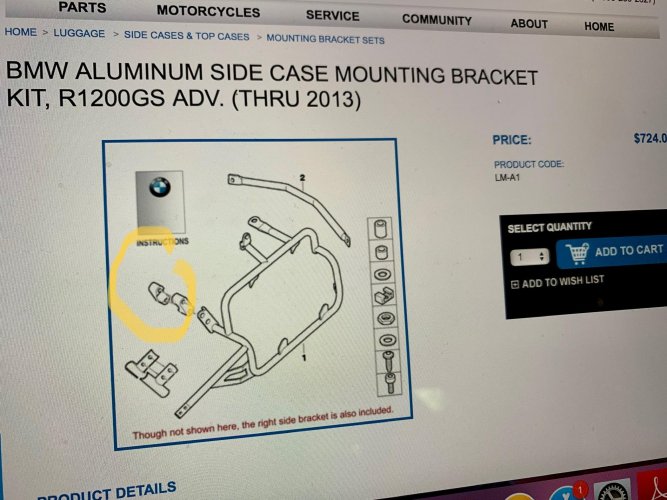

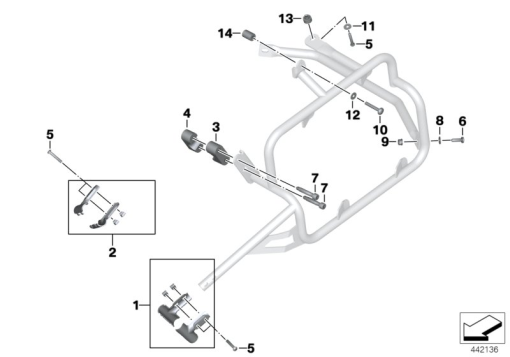

I've circled the part in yellow on a pic below - which lists the whole left case rack assembly for sale but does mention BMW sells the bits separately.

My local dealer is closed due to the pandemic and I'm not able to find the part number, much less any for sale.

Any help would be greatly appreciated.

And...if I do find one, I have promised myself that I will respect stainless threaded into aluminum and will apply anti-seize compound!

First it broke off leaving a protruding remnant. I gave it another week of soaking with Kroil (this penetrant has worked for me when others did not)

I made a "coupler" with a nut and threaded the two pieces back together and reworded them. I was glad to have the whole unit easy to work with!

The bolt rung off again, this time flush.

Argh. Plan B - centerpunch and start drilling Pretty easy securing the unit in a drill press vise versus by hand as if often the only option.

After committing to through-drilling the whole thing and either re-tapping or going to a "heli-coil" type thread repair insert - I was on step 3 of slightly larger bits when I broke the bit! Perfectly flush and I can't get it out.

I don't think I'll have any success flailing on this further.

I'm prepared to make a bracket (out of steel) but would like to find one for sale new or used if possible.

I've circled the part in yellow on a pic below - which lists the whole left case rack assembly for sale but does mention BMW sells the bits separately.

My local dealer is closed due to the pandemic and I'm not able to find the part number, much less any for sale.

Any help would be greatly appreciated.

And...if I do find one, I have promised myself that I will respect stainless threaded into aluminum and will apply anti-seize compound!