The articles, posts and comments in this tech section are posted by individual members and reflect their personal thoughts and experiences with repairing, maintaining, and generally working on motorcycles. This information may require specific knowledge and skills, may or may not be correct or current to model.

The authors of information found here and the BMW MOA take no responsibility for ensuring the accuracy of any information (including procedures, techniques, parts numbers, torque values, tool usage, etc.), or further for any damage of any kind or injuries incurred or caused by anyone following the instructions or information found here.

It is the duty of the individual to either assume the liability himself for responsibly using the information found here, or to take the bike or accessory to a Dealer or other qualified professional service.

Please ensure you dispose of your used chemicals, oils and fuels in an environmentally responsible manner. Most Auto Parts stores and service stations will accept used oil and lubricants, tires and batteries, please check for your local availability. Here's a link where you can look up a place to dispose of your used fluids (oil, coolant, brake fluid, etc.) - http://earth911.com/

This article, text and photos are Copyright of the individual authors and the BMW MOA, any copying or redistributing is permitted only by prior written authorization.

PLEASE PRINT AND READ ALL THE INSTRUCTIONS BEFORE BEGINNING!

Final note: The motorcycle's two wheels are the only thing keeping you upright. When in doubt, take your motorcycle to a reputable dealer.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Setting the proper chain tension on your BMW F-Twin with a chain drive

Even with proper lubrication, over time our chain and sprockets will wear out. The chain will "stretch" as various portions of the chain wear down, and the sprockets will deform as the metal wears away. This creates chain slack. There are many variables that go into how long a chain/sprocket will last and how much slack is created throughout the life of the chain. Lubrication and cleaning schedule, O-ring/X-ring life, time/miles spent in the rain, if you live in an area with a lot of sand, or if you ride off-road a lot will all have an effect on the chain/sprocket life. You probably can't see this slack from one pin to the next, but multiply it by the 100's of pins in a chain, and you can end up with a lot of slack. Too much slack will cause excess wear on the chain sliders, rubber dampeners, and can cause the bike to ride a bit rough. If the chain is too tight, you can create excess wear on the sprockets and drive system.

It's generally recommended to check your chain slack every 500 miles and probably a bit more frequently if you ride a lot off-road. I have noticed that as your chain gets towards the end of its life, you require more frequent chain slack adjustments.

For the BMW F-Twins, we check our chain slack with the bike on the side stand.

There's a sticker on your swing arm that notes how much slack there should be.

For the F800GS - BMW recommends a chain slack of 35 to 45 millimeters. (1.4 to 1.8 inches)

For the F700GS - BMW recommends a chain slack of 30 to 40 millimeters. (1.2 to 1.6 inches)

For the F650GS - BMW recommends a chain slack of 30 to 40 millimeters. (1.2 to 1.6 inches)

For the F800R - BMW recommends a chain slack of 30 to 40 millimeters. (1.2 to 1.6 inches)

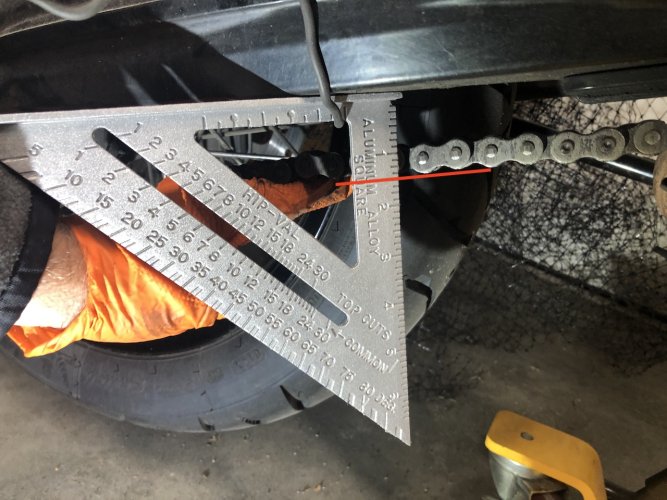

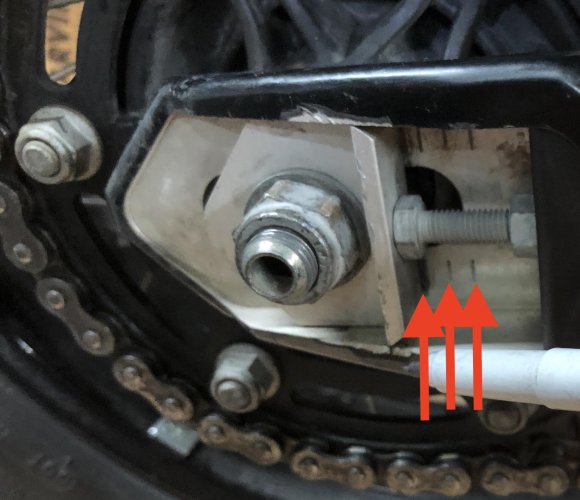

We can also check to see if it's time to replace the chain/sprockets by measuring how much distance there is between 9 chain pins. BMW states for all F-Twin models that the max distance over 9 pins is to be no more than 144.30 mm (5.7 inches).

Note 1: The specific bike shown is a 2013 F800GS, but there doesn't appear to be any difference between models or years (other than the above slack differences)

Note 2: The tools and materials used are by personal choice and are not due to any affiliation with any brand

Tools Required:

- 24 mm socket

- Ratchet that fit the above

- Breaker bar (optional, but may be needed as the axle nut is quite tight)

- 13 mm open ended wrench

- Torque wrench

- Measuring device

The authors of information found here and the BMW MOA take no responsibility for ensuring the accuracy of any information (including procedures, techniques, parts numbers, torque values, tool usage, etc.), or further for any damage of any kind or injuries incurred or caused by anyone following the instructions or information found here.

It is the duty of the individual to either assume the liability himself for responsibly using the information found here, or to take the bike or accessory to a Dealer or other qualified professional service.

Please ensure you dispose of your used chemicals, oils and fuels in an environmentally responsible manner. Most Auto Parts stores and service stations will accept used oil and lubricants, tires and batteries, please check for your local availability. Here's a link where you can look up a place to dispose of your used fluids (oil, coolant, brake fluid, etc.) - http://earth911.com/

This article, text and photos are Copyright of the individual authors and the BMW MOA, any copying or redistributing is permitted only by prior written authorization.

PLEASE PRINT AND READ ALL THE INSTRUCTIONS BEFORE BEGINNING!

Final note: The motorcycle's two wheels are the only thing keeping you upright. When in doubt, take your motorcycle to a reputable dealer.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Setting the proper chain tension on your BMW F-Twin with a chain drive

Even with proper lubrication, over time our chain and sprockets will wear out. The chain will "stretch" as various portions of the chain wear down, and the sprockets will deform as the metal wears away. This creates chain slack. There are many variables that go into how long a chain/sprocket will last and how much slack is created throughout the life of the chain. Lubrication and cleaning schedule, O-ring/X-ring life, time/miles spent in the rain, if you live in an area with a lot of sand, or if you ride off-road a lot will all have an effect on the chain/sprocket life. You probably can't see this slack from one pin to the next, but multiply it by the 100's of pins in a chain, and you can end up with a lot of slack. Too much slack will cause excess wear on the chain sliders, rubber dampeners, and can cause the bike to ride a bit rough. If the chain is too tight, you can create excess wear on the sprockets and drive system.

It's generally recommended to check your chain slack every 500 miles and probably a bit more frequently if you ride a lot off-road. I have noticed that as your chain gets towards the end of its life, you require more frequent chain slack adjustments.

For the BMW F-Twins, we check our chain slack with the bike on the side stand.

There's a sticker on your swing arm that notes how much slack there should be.

For the F800GS - BMW recommends a chain slack of 35 to 45 millimeters. (1.4 to 1.8 inches)

For the F700GS - BMW recommends a chain slack of 30 to 40 millimeters. (1.2 to 1.6 inches)

For the F650GS - BMW recommends a chain slack of 30 to 40 millimeters. (1.2 to 1.6 inches)

For the F800R - BMW recommends a chain slack of 30 to 40 millimeters. (1.2 to 1.6 inches)

We can also check to see if it's time to replace the chain/sprockets by measuring how much distance there is between 9 chain pins. BMW states for all F-Twin models that the max distance over 9 pins is to be no more than 144.30 mm (5.7 inches).

Note 1: The specific bike shown is a 2013 F800GS, but there doesn't appear to be any difference between models or years (other than the above slack differences)

Note 2: The tools and materials used are by personal choice and are not due to any affiliation with any brand

Tools Required:

- 24 mm socket

- Ratchet that fit the above

- Breaker bar (optional, but may be needed as the axle nut is quite tight)

- 13 mm open ended wrench

- Torque wrench

- Measuring device

Last edited: