bigjohnsd

'21 R1250 GS Adv

Quote

Over 400,000 BMW GS for cardan check

Major construction sites in the BMW workshops: The cardan is to be checked and a vent valve retrofitted on a total of 440,000 motorcycles worldwide, especially on the R 1250 GS and R 1200 GS from 2013.

"In order to improve long-term quality", according to BMW Motorrad's official formulation, the authorized workshops are currently being prepared for a very extensive service campaign: the cardan shafts of a total of 440,000 motorcycles worldwide are to be checked over the course of the next few months, ideally as part of the scheduled inspections will. 72,000 of them in Germany alone. The campaign primarily affects BMW's most important model: the boxer GS. Specifically, the R 1250 GS and the R 1200 GS from year of manufacture 2013, both type K50, as well as the respective adventure variants, type K51. In addition, there is the official version RT, type K52.

Universal joint, articulation angle, corrosion

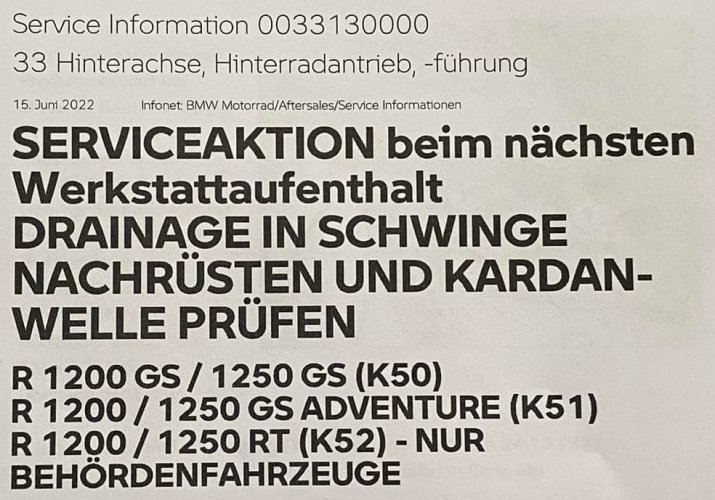

Background according to BMW, from a message to the dealers: "Service campaign during the next visit to the workshop - retrofit drainage in the swingarm and check the cardan shaft. Damage to the cardan shaft occasionally occurs, which impairs the function of the drive. In individual cases, propulsion can be lost Several factors contribute to the occurrence of damage.Corrosion effects, among others, play a role if they occur at functionally relevant points.Signs of wear caused by running time or particular climatic and dynamic loads can also lead to component damage. These effects can be caused by the geometric chassis design (kink angle of the universal joints in the swing arm) be reinforced."

R 1200 GS, R 1250 GS and official RT

Apparently, a conspicuous accumulation of cardan defects was found in the Boxer GS from year of manufacture 2013 (with water-cooled engine) and in the R 1200 RT and R 1250 RT in the official version. With the GS, the cardan is subject to greater stress due to the concept, because of the longer spring deflection and the associated articulation angle between the cardan tunnel and the rear axle drive. This is where the cardan's rear universal joint is located. In addition, depending on the user, there is more or less tough enduro use. In any case, the authorities' RT are subjected to above-average strain, for example when driving over high curbs.

Cardan check with special device

So that the cardan does not have to be opened on all 440,000 motorcycles concerned, every authorized workshop is to be given a special test device. Instead of the rear wheel, a measuring disk is mounted, and then the cardan is dragged over the rear axle while idling, that is, rotated. This stress test runs over various load changes and speeds, with sensors monitoring the forces and vibrations. If everything stays within the predefined normal range, the checked gimbal is considered "okay". If there are any abnormalities, a closer look is taken. In particular, the universal joint with its four roller bearings, but also the gearing to the rear axle drive is checked for rust and damage. Should parts then have to be replaced,

Vent hole with beak valve

In principle, a vent on the cardan tunnel is retrofitted during this service campaign. For this purpose, a small hole is drilled on the underside in the rear area, near the universal joint, using a prepared template. In order to avoid the formation of potentially harmful metal chips, the drill should be lubricated beforehand. A rubber beak valve is then inserted into this hole using a kind of piercing tool. This special valve is intended to seal the hole to the outside, but allow air and, above all, moisture to escape from the cardan tunnel. This ventilation is supported by the pumping movements during compression and rebound. If water runs out immediately after drilling, this is also a reason to inspect the cardan more closely.

45 minutes per motorcycle

A total of 45 minutes are allotted for the cardan check including retrofitting the ventilation. Of course, this campaign is free of charge - at least for the customers, BMW will incur some costs.

End Quote

A pain in the ass but Google Translate prevailed!

https://www-motorradonline-de.trans...l=auto&_x_tr_tl=en&_x_tr_hl=en&_x_tr_pto=wapp

Over 400,000 BMW GS for cardan check

Major construction sites in the BMW workshops: The cardan is to be checked and a vent valve retrofitted on a total of 440,000 motorcycles worldwide, especially on the R 1250 GS and R 1200 GS from 2013.

"In order to improve long-term quality", according to BMW Motorrad's official formulation, the authorized workshops are currently being prepared for a very extensive service campaign: the cardan shafts of a total of 440,000 motorcycles worldwide are to be checked over the course of the next few months, ideally as part of the scheduled inspections will. 72,000 of them in Germany alone. The campaign primarily affects BMW's most important model: the boxer GS. Specifically, the R 1250 GS and the R 1200 GS from year of manufacture 2013, both type K50, as well as the respective adventure variants, type K51. In addition, there is the official version RT, type K52.

Universal joint, articulation angle, corrosion

Background according to BMW, from a message to the dealers: "Service campaign during the next visit to the workshop - retrofit drainage in the swingarm and check the cardan shaft. Damage to the cardan shaft occasionally occurs, which impairs the function of the drive. In individual cases, propulsion can be lost Several factors contribute to the occurrence of damage.Corrosion effects, among others, play a role if they occur at functionally relevant points.Signs of wear caused by running time or particular climatic and dynamic loads can also lead to component damage. These effects can be caused by the geometric chassis design (kink angle of the universal joints in the swing arm) be reinforced."

R 1200 GS, R 1250 GS and official RT

Apparently, a conspicuous accumulation of cardan defects was found in the Boxer GS from year of manufacture 2013 (with water-cooled engine) and in the R 1200 RT and R 1250 RT in the official version. With the GS, the cardan is subject to greater stress due to the concept, because of the longer spring deflection and the associated articulation angle between the cardan tunnel and the rear axle drive. This is where the cardan's rear universal joint is located. In addition, depending on the user, there is more or less tough enduro use. In any case, the authorities' RT are subjected to above-average strain, for example when driving over high curbs.

Cardan check with special device

So that the cardan does not have to be opened on all 440,000 motorcycles concerned, every authorized workshop is to be given a special test device. Instead of the rear wheel, a measuring disk is mounted, and then the cardan is dragged over the rear axle while idling, that is, rotated. This stress test runs over various load changes and speeds, with sensors monitoring the forces and vibrations. If everything stays within the predefined normal range, the checked gimbal is considered "okay". If there are any abnormalities, a closer look is taken. In particular, the universal joint with its four roller bearings, but also the gearing to the rear axle drive is checked for rust and damage. Should parts then have to be replaced,

Vent hole with beak valve

In principle, a vent on the cardan tunnel is retrofitted during this service campaign. For this purpose, a small hole is drilled on the underside in the rear area, near the universal joint, using a prepared template. In order to avoid the formation of potentially harmful metal chips, the drill should be lubricated beforehand. A rubber beak valve is then inserted into this hole using a kind of piercing tool. This special valve is intended to seal the hole to the outside, but allow air and, above all, moisture to escape from the cardan tunnel. This ventilation is supported by the pumping movements during compression and rebound. If water runs out immediately after drilling, this is also a reason to inspect the cardan more closely.

45 minutes per motorcycle

A total of 45 minutes are allotted for the cardan check including retrofitting the ventilation. Of course, this campaign is free of charge - at least for the customers, BMW will incur some costs.

End Quote

A pain in the ass but Google Translate prevailed!

https://www-motorradonline-de.trans...l=auto&_x_tr_tl=en&_x_tr_hl=en&_x_tr_pto=wapp