biotechbill

New member

Non-Gearhead here doing some service on my 2011 R1200RT in preperation for my trip to the MOA rally in Des Moines; which for me will be upwards of a 3000-4000 mile trip as I'm visiting family in Missouri & Iowa in the process.

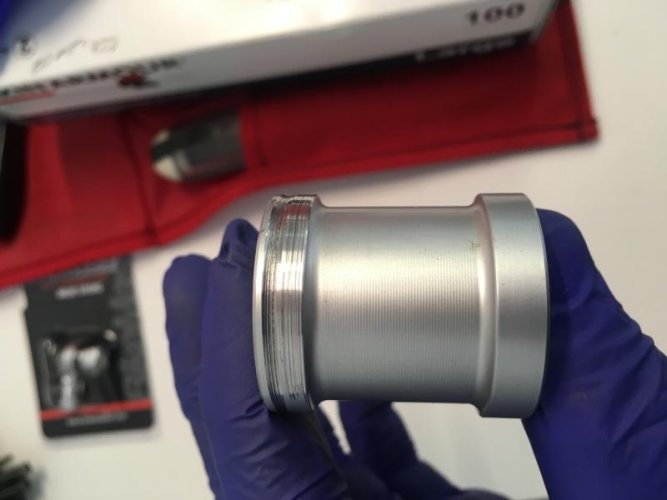

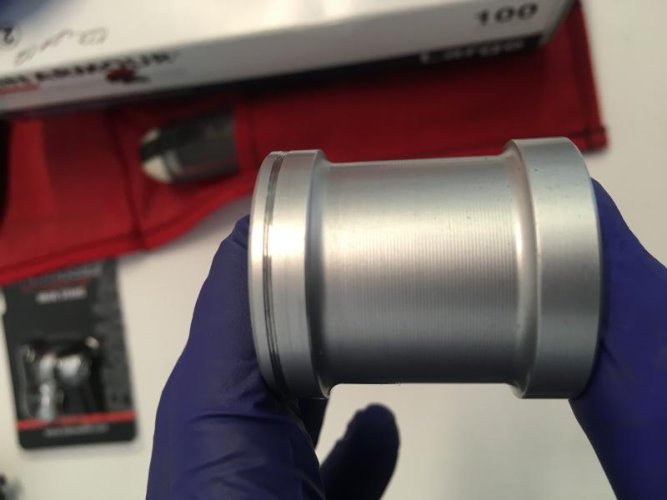

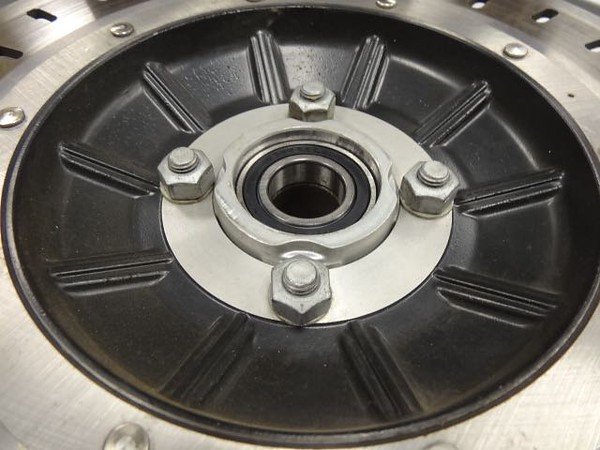

Most recent work done was changing tires and brakes last weekend. All went well but when cleaning up the front wheel spacer found some wear on the outer surface on the side facing the wheel bearings. Wasn't much, if any, grease in that area so applied some automotive lithium grease to outer edge of both bearings and axle before putting everything back together.

Question is this; is the wear on the spacer a problem and is it indicative of a larger problem with the wheel bearings? Should I replace the spacer and/or the wheel bearings just to be safe. I don't seem to have any play in the wheel and it seems to turn smoothly from what I can tell not being a gearhead.

This is probably my first post ever, on any forum, so I hope I've made myself clear and that the two photos I'm attaching are visible with this post.

Thanks in advance for any advice you can give.

Blind Cragg

Former Harley, Rice Burner owner and now a BMW convert.

Most recent work done was changing tires and brakes last weekend. All went well but when cleaning up the front wheel spacer found some wear on the outer surface on the side facing the wheel bearings. Wasn't much, if any, grease in that area so applied some automotive lithium grease to outer edge of both bearings and axle before putting everything back together.

Question is this; is the wear on the spacer a problem and is it indicative of a larger problem with the wheel bearings? Should I replace the spacer and/or the wheel bearings just to be safe. I don't seem to have any play in the wheel and it seems to turn smoothly from what I can tell not being a gearhead.

This is probably my first post ever, on any forum, so I hope I've made myself clear and that the two photos I'm attaching are visible with this post.

Thanks in advance for any advice you can give.

Blind Cragg

Former Harley, Rice Burner owner and now a BMW convert.