Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1975 R90/6 600 Mile Service post rebuild

- Thread starter clmedlin

- Start date

Yes SirDid you confirm that the pressure relief valve operates correctly?

52184

GTRider

Attaching an oil pressure gauge will eliminate the possibility of a bad sending unit. Beyond that, I’d expect the next three things to check would be proper sealing of the filter cannister, the possibility of a broken or weak spring on the relief valve (it may spring back when pressed, but at what pressure?), or a failed woodruff key on the oil pump.Replaced the center pipe. Oil pressure light is still on…….

Best,

DeVern

I tested the pressure again - it’s less than 4 psi which is the bottom of my gauge (Lang). I have confirmed the switch works with my multi meter. I will drain the oil and confirm the canister and pressure relief valve - Is there a pressure test for the relief valve?Attaching an oil pressure gauge will eliminate the possibility of a bad sending unit. Beyond that, I’d expect the next three things to check would be proper sealing of the filter cannister, the possibility of a broken or weak spring on the relief valve (it may spring back when pressed, but at what pressure?), or a failed woodruff key on the oil pump.

Best,

DeVern

If neither of this show me anything - I guess I’ll have to pull the engine.

Thank you for you assistance.

The pressure relief valve works - no precise measurement of spring activation

The oil pump primed the system - there was oil in the canister and the oil filter was saturated.

Upon removing the outer oil cover, there was a noticeable amount of oil pooling outside of the inner cover.

Could my pressure loss be coming from the inner cover not sealing? I am fairly certain, there is no Oring on the cover.

I really don’t want to drop the engine!

The oil pump primed the system - there was oil in the canister and the oil filter was saturated.

Upon removing the outer oil cover, there was a noticeable amount of oil pooling outside of the inner cover.

Could my pressure loss be coming from the inner cover not sealing? I am fairly certain, there is no Oring on the cover.

I really don’t want to drop the engine!

Attachments

There isn't an o-ring on the cover, but there should be a square black o-ring on the outside end of the filter. You an see the small circle in the cap where that o-ring would sit. I don't believe the cap is supposed to seal around the outer edge of the filter but rather just hold it securely in place.

Not sure there's a test for the pressure relief ball bearing...I think it's supposed to open at 75 psi. So one would expect there to be reasonable pressure by the spring on the ball when you reach in there. If it moves easily, that could be a problem.

Not sure there's a test for the pressure relief ball bearing...I think it's supposed to open at 75 psi. So one would expect there to be reasonable pressure by the spring on the ball when you reach in there. If it moves easily, that could be a problem.

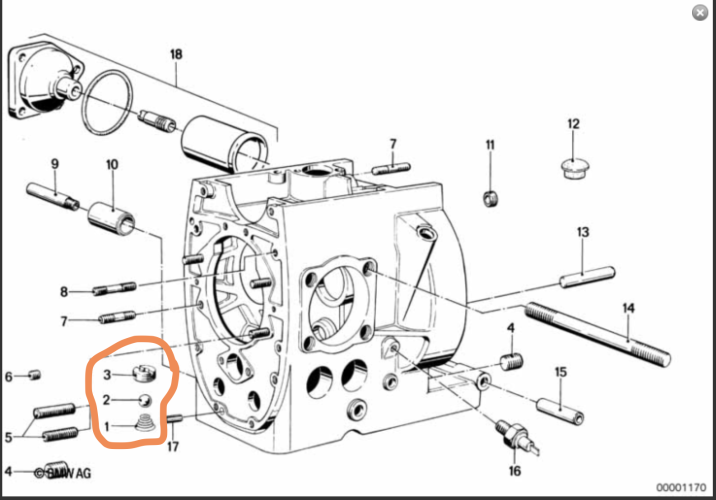

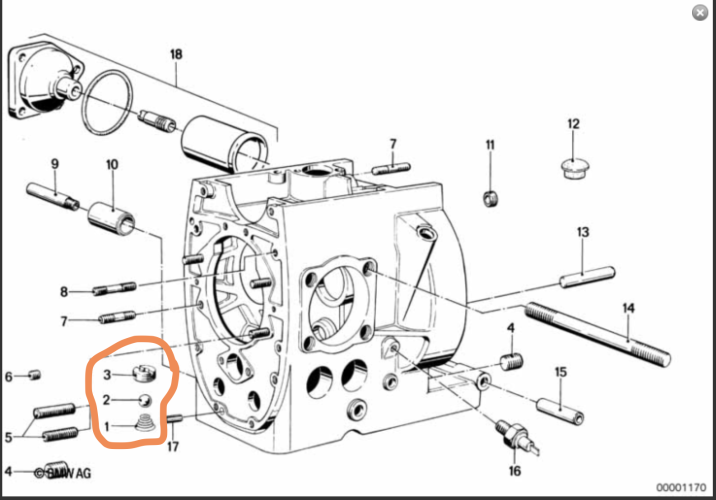

I don't want to get into the habit of replacing parts - just to replace parts, but the pressure relief valve is pretty inexpensive and is now easy to get to. Looking on the max bmw parts fiche, it looks like its 3 separate components and I will purchase them just to check this off my potential list of issues.

I've checked everything DeVern recommended, so I guess I just need to drop the engine to get to the oil pump and woodruff key.

I've checked everything DeVern recommended, so I guess I just need to drop the engine to get to the oil pump and woodruff key.

52184

GTRider

I wouldn’t jump right into pulling the trans and clutch to check the pump, not until after checking the easier bits first. Did you answer Kurt’s question on the outer o-ring that comes with the filter? Was it in place?

On the pressure relief valve, 75psi is a fairly significant pressure. You should be able to reach in with a rod or dowel and get an idea of how much spring tension is behind the ball and also whether or not the ball is returning freely and seating.

Best,

DeVern

Edit: Also, has the pan been dropped to make sure the oil pump pickup is not loose?

On the pressure relief valve, 75psi is a fairly significant pressure. You should be able to reach in with a rod or dowel and get an idea of how much spring tension is behind the ball and also whether or not the ball is returning freely and seating.

Best,

DeVern

Edit: Also, has the pan been dropped to make sure the oil pump pickup is not loose?

Last edited:

Center pipe, 1 piece oil filter, ball check valve, sump screen, sump gasket all replaced. Valve clearance confirmed/re-guaged. Used compressed air to blow from sump and from center pipe to eliminate possible clog. 4-6 psi at 1000 rpm. 18 psi at 2500. Snowbum identifies oil pressure should 14-29 psi at idle.

The pressure relief valve is in the front of the engine, above the timing chain. That’s the next step in order of pain before pulling engine.

The pressure relief valve is in the front of the engine, above the timing chain. That’s the next step in order of pain before pulling engine.

Could my Spring in the pressure valve be the source of my low oil pressure? I pulled the valve and the spring measures 67.61mm - the spec in the tech manual is 68. When assembled the piston seemed sluggish in the hollow pin and the spring did not seem to provide much “spring” back action.

Any insight would be appreciated.

Any insight would be appreciated.

Attachments

Yes - but do you think it’s an indicator of spring fatigue? My understanding of the valve and how it affects oil pressure is pretty basic - if the valve gets stuck open, it causes a drop in oil pressure. If the valve gets stuck close, it causes pressure to rise. I am not sure how to measure or gauge a spring to ensure it’s within spec or that the valve is operating correctly. So I am going to replace the spring and piston.0.4mm difference? That doesn't strike me as a significant amount.

Last edited:

pauls1150

MOA #24991, south of Los Angeles

0.4 mm is about 0.015" ... more than our exhaust valve clearance spec ... The true test of a spring is how much force is required to compress it over a known distance. Lacking that info, I'd replace it.

Is that piston worn? The pic magnified shows what may be a little scoring; if it is, how's the inside of the tube?

Is that piston worn? The pic magnified shows what may be a little scoring; if it is, how's the inside of the tube?

Very minimal scoring. After cleaning everything - the entire valve assembly functions much smoother, but I am going to still going to replace the spring and piston. The hollow pin is NLA. Outside of the center pipe, I just feel like I’m replacing parts, not knowing if they were contributing to the low oil pressure.

kinterridge

Member

You might be able to get the spring tested, if you have machine shop that does head work or clutch work. They have a psi gauge tool for testing valve and clutch springs. It can be set up on vise or drill press or small shop press. The rating on the spring is 75 PSI so I'd be looking for no more than 100 psi guage set up. Racing suppliers sell the gauge set up as well. Just my guess but if its short its fatigued.

Similar threads

- Replies

- 9

- Views

- 418