gtgt_bangbang

New member

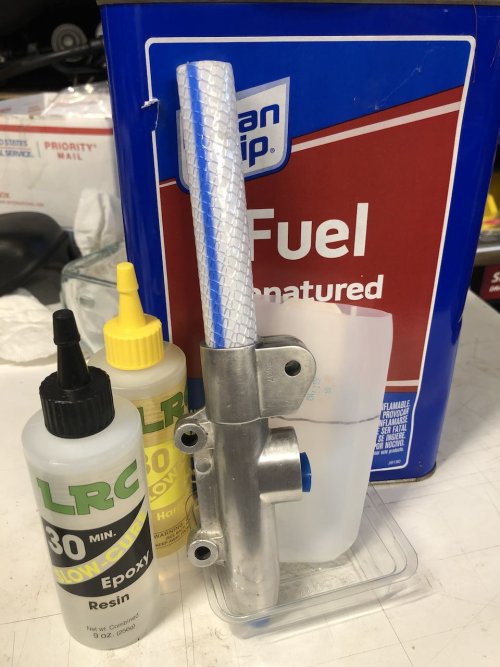

Took apart rear master cylinder awhile back , the usual suspect Reference sources iffy / incomplete at~best .

The Brembo kit comes with a poster-sized instruction sheet written with faded 6-pt type and not one diagram fully matches the piston / seal stack here.

Bravo ! but why should you let Brembo Stop ya ?

Picture below sure LOOKS like the proper stack but before assembling , I'd prefer to get some practiced eyes on this ,

as the rearmost keeper ring is not a circlip style, rather this is a 1-time drive-in parts ( no mulligans ) . Needs 21.5 mm (max) drift

Can any one recall if this is correct assembly order & orientation ? TIA

the drive-in ring is tapered, going to drive into bore w/ smaller ID headmost.

The flat washer just looks like a back-up for the outermost seal.

This outer seal is a step / taper , also planning on narrow OD first.

The piston is a natural with Flared lips FLARE headmost ( as an expand-against-pressure seal, seals installed at MFG on new piston in kit)

and the internal return spring is a secure fit only on one end of piston,

finally the 'stove pipe hat' grommet is well fitted into spring , cushions the far (outlet) end of cylinder with a hole for fluid passage.

The feed tube grommet is not in the rebuild kit nor BMW catalog, but I located a match under a Duc part number.

Fortunately too, since it was the crappiest part on the original master. But don't let Brembo Stop ya.; put it in the kit, wont ya?

So if you know the stack, please agree with the order & orientation below , or set me straight.

Otherwise , take this diagram to guide your work & your very welcome. Then I can use the instructions as an emergency blanket.

The Brembo kit comes with a poster-sized instruction sheet written with faded 6-pt type and not one diagram fully matches the piston / seal stack here.

Bravo ! but why should you let Brembo Stop ya ?

Picture below sure LOOKS like the proper stack but before assembling , I'd prefer to get some practiced eyes on this ,

as the rearmost keeper ring is not a circlip style, rather this is a 1-time drive-in parts ( no mulligans ) . Needs 21.5 mm (max) drift

Can any one recall if this is correct assembly order & orientation ? TIA

the drive-in ring is tapered, going to drive into bore w/ smaller ID headmost.

The flat washer just looks like a back-up for the outermost seal.

This outer seal is a step / taper , also planning on narrow OD first.

The piston is a natural with Flared lips FLARE headmost ( as an expand-against-pressure seal, seals installed at MFG on new piston in kit)

and the internal return spring is a secure fit only on one end of piston,

finally the 'stove pipe hat' grommet is well fitted into spring , cushions the far (outlet) end of cylinder with a hole for fluid passage.

The feed tube grommet is not in the rebuild kit nor BMW catalog, but I located a match under a Duc part number.

Fortunately too, since it was the crappiest part on the original master. But don't let Brembo Stop ya.; put it in the kit, wont ya?

So if you know the stack, please agree with the order & orientation below , or set me straight.

Otherwise , take this diagram to guide your work & your very welcome. Then I can use the instructions as an emergency blanket.