brittrunyon

'92 R100GS

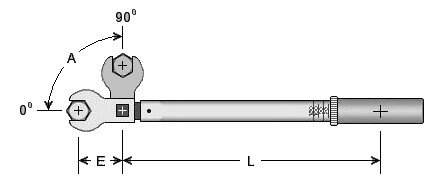

After doing a spline lube, I went to buttoning up the trani to the block.

Snobum says 15 ft.lbs...........I say OK.

.........but how the Hell do I (we) get a torque wrench on those four bolts?

..........(2 in the air box & the 2 lowers, R & L)

(images say a thousand words)

<a href="https://www.flickr.com/photos/brittrunyon/17118925049" title="Transmission Bolt_8380 by Britt Runyon Photography, on Flickr"><img src="https://farm9.staticflickr.com/8711/17118925049_3e21365b3e_b.jpg" width="1024" height="778" alt="Transmission Bolt_8380"></a>

Snobum says 15 ft.lbs...........I say OK.

.........but how the Hell do I (we) get a torque wrench on those four bolts?

..........(2 in the air box & the 2 lowers, R & L)

(images say a thousand words)

<a href="https://www.flickr.com/photos/brittrunyon/17118925049" title="Transmission Bolt_8380 by Britt Runyon Photography, on Flickr"><img src="https://farm9.staticflickr.com/8711/17118925049_3e21365b3e_b.jpg" width="1024" height="778" alt="Transmission Bolt_8380"></a>