Scarletswirl

New member

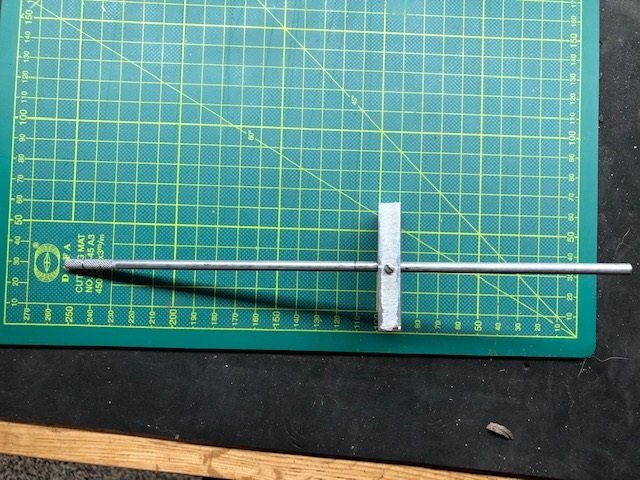

Yesterday I started hearing some awful noises from the front of the bike and realized that the fairing was loose. At first I thought one of the bolts had loosed up or fallen out, but when I started disassembly I realized that the upper bracket had detached from the frame. The plate where the fasteners go through separated from the rest of the bracket, probably due to fatigue failure. See attached picture.

The bike has less than 20K miles.

This leads to several questions:

1. Has anyone run into this before? Is this considered a 'common' failure? Anything that can be done to prevent it in the future?

2. I have a friend who is pretty good at welding and is willing to weld the fatigue cracks shown in the picture. Would that work, or should I look for a good used part?

3. The part is no longer available from BMW. However, it is available on ebay. Here's the rub. There are two parts numbers for it, one that goes on earlier bikes (46 63 1 237 932 up to '83?) and the other from '84 on (46 63 1 452 476). For some reason, the early ones seem more abundant and also cheaper. Does anyone know whether they are interchangeable and if one type is better than the other?

As always, thanks for any input.

The bike has less than 20K miles.

This leads to several questions:

1. Has anyone run into this before? Is this considered a 'common' failure? Anything that can be done to prevent it in the future?

2. I have a friend who is pretty good at welding and is willing to weld the fatigue cracks shown in the picture. Would that work, or should I look for a good used part?

3. The part is no longer available from BMW. However, it is available on ebay. Here's the rub. There are two parts numbers for it, one that goes on earlier bikes (46 63 1 237 932 up to '83?) and the other from '84 on (46 63 1 452 476). For some reason, the early ones seem more abundant and also cheaper. Does anyone know whether they are interchangeable and if one type is better than the other?

As always, thanks for any input.