I replaced the HES this past week on my 2010 R1100RS. I've had the bike a couple years and decided to put a new belt on as well since I wasn't sure when it had last been replaced (currently 68,000 miles). Read the Clymer and watched video to properly adjust the tension on the belt and got to it. UNFORTUNATELY, I didn't remember (or never realized) that the reverse on my torque wrench wasn't for measuring torque. I thought I'd learned my lessons about if it feels wrong, it probably is. Regardless, I torqued down way too hard and cracked the tensioner nut (Clymer calls it an idler I think). Does anyone know where I can find one of these?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nube error - Messed up on alternator belt tensioning

- Thread starter mhallman

- Start date

I'm going to assume you mean 2001 R1100RS. I believe the part # is 12 31 7 677 914.

Available from your local BMW dealer or online from MAX BMW.

https://shop.maxbmw.com/fiche/DiagramsMain.aspx?vid=51676&rnd=07242017

Diagram # 12_0767 in Section 12 - Engine Electrics.

Available from your local BMW dealer or online from MAX BMW.

https://shop.maxbmw.com/fiche/DiagramsMain.aspx?vid=51676&rnd=07242017

Diagram # 12_0767 in Section 12 - Engine Electrics.

pglaves

#13338

Thanks for that. Will bookmark this page for future use. Off to get a reversible torque wrench...

You do not need to overthink this. It is just a rubber drive belt. If you tighten the belt until you are able to twist it 90 degrees at the midpoint between the pulleys you will be just fine. That is not too tight. If it is too loose it will squeak on engine startup. If it were too tight the part that would be damaged is the front bearing in the alternator. I used this technique on my R1150R. That alternator was still alternating at 177,000 miles when I sold the bike. I use this technique on Voni's R1100RS and the alternator is still OK at 412,000 miles. The commutator is a bit grooved but the bearing is fine.

riderr1150gsadv

Well-known member

I have used the method of belt tensioning that Paul mentioned for many years as well.

This 90 degree tension check is actually spot on when you check it with a torque wrench..YMMV

This 90 degree tension check is actually spot on when you check it with a torque wrench..YMMV

dieselyoda

Active member

They do make belt tension gauges that are easy to use. Universal application.

pglaves

#13338

They do make belt tension gauges that are easy to use. Universal application.

If you know what the tension spec is supposed to be? Or is it a universal value?

gsaddict

Pepperfool

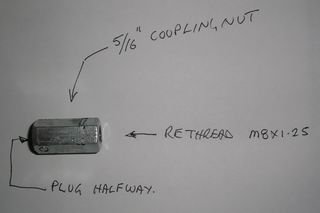

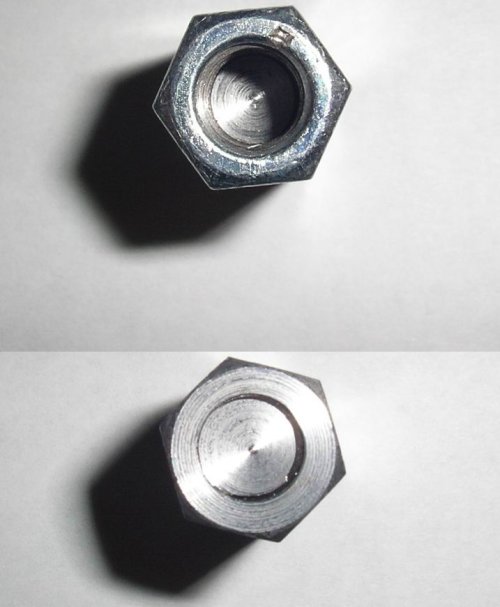

Or you can torque to spec from the front with the BMW special tool

https://shop.maxbmw.com/fiche/PartsDetails.aspx?source=catalog&vid=51672&diagram=ST_12 3 551

per service bulletin 12 001 02

or make your own.

https://shop.maxbmw.com/fiche/PartsDetails.aspx?source=catalog&vid=51672&diagram=ST_12 3 551

per service bulletin 12 001 02

or make your own.

Attachments

dieselyoda

Active member

If you know what the tension spec is supposed to be? Or is it a universal value?

There are a bunch of them out there based on the belt only. I recently saw Gates used a piece of tape. You applied the tape to the belt. You tightened the belt and when the tape broke, that was the perfect tension for the belt.

after market made?

To GSaddict

Has anyone gotten adventurous and made these to sell, other than BMW?

To GSaddict

Or you can torque to spec from the front with the BMW special tool

https://shop.maxbmw.com/fiche/PartsDetails.aspx?source=catalog&vid=51672&diagram=ST_12 3 551

per service bulletin 12 001 02 or make your own.

Has anyone gotten adventurous and made these to sell, other than BMW?

gsaddict

Pepperfool

To GSaddict

Has anyone gotten adventurous and made these to sell, other than BMW?

I have made up several as per post. The cost of shipping makes it almost the same as buying from BMW.

RPGR90s

Member

You do not need to overthink this. It is just a rubber drive belt. If you tighten the belt until you are able to twist it 90 degrees at the midpoint between the pulleys you will be just fine. That is not too tight. If it is too loose it will squeak on engine startup. If it were too tight the part that would be damaged is the front bearing in the alternator. I used this technique on my R1150R. That alternator was still alternating at 177,000 miles when I sold the bike. I use this technique on Voni's R1100RS and the alternator is still OK at 412,000 miles. The commutator is a bit grooved but the bearing is fine.

What Paul said. Been doing the 90 degree twist on my 2004 RT since it was new. Now currently at 129k, and on the original alternator with only a couple of belt changes.

Don't over think it.

I have made up several as per post. The cost of shipping makes it almost the same as buying from BMW.

But you make the profit...

gsaddict

Pepperfool

But you make the profit...

Hardly worth it if you factor in fuel and time to mail.

pglaves

#13338

But you make the profit...

Oh, I hope he does.