My '94 R100R with 15K miles suddenly after decelerating from highway speed went into neutral and wouldn't engage any gear. The clutch pull became abnormally light. The clutch cable and external linkage all appear intact. After rotating the the rear wheel back and forth with the bike on the centerstand, shifting gears and jogging the engine with the starter motor, the transmission and engine became engaged again. I made it home (~20 miles) but the trans went into all neutrals 2 more times, both times after a deceleration to a stop. I was able to engage it both times after jogging the engine and rotating the rear wheel. I am the 3rd owner and am unaware of the circlip status. Any suggestions as to the root cause would be appreciated.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

All neutrals after deceleration

- Thread starter murty

- Start date

-

- Tags

- clutch r100r transmission

gtrider

52184

That sounds more like a sticking clutch throwout piston on the back of the transmission—did you only roll off the throttle to decelerate, or did you roll off and also pull the clutch to downshift? Some variants of the throwout piston were known to swell and stick, so before worrying about the tranny I’d pull that piston and check it. The tip-off is your statement that the clutch pull got very light.

IMHO, of course.

Best,

DeVern

IMHO, of course.

Best,

DeVern

kinterridge

Member

That sounds more like a sticking clutch throwout piston on the back of the transmission—did you only roll off the throttle to decelerate, or did you roll off and also pull the clutch to downshift? Some variants of the throwout piston were known to swell and stick, so before worrying about the tranny I’d pull that piston and check it. The tip-off is your statement that the clutch pull got very light.

IMHO, of course.

Best,

DeVern

Yes I pulled in the clutch to downshift during decelerations. Can the throwout piston be accessed without removing the transmission?

Can the throwout piston be accessed without removing the transmission?

Yes, look at the fiche drawing and remove the items that are outside the transmission. Do not try and remove the long pushrod that goes through the middle of the transmission.

Yes, look at the fiche drawing and remove the items that are outside the transmission. Do not try and remove the long pushrod that goes through the middle of the transmission.

Thanks for your help on this.

I removed the parts and and the piston was well-lubricated and slid out easily. The boot and other parts seem to be in good shape.

Should I replace the piston? Or something else?

Best regards,

Paul

There was a period of time when that piston was prone to swelling due to heat and then jamming in the bore of the transmission. Don't know which period that was though! Snowbum mentions the "sticky hot piston" on this page:

https://bmwmotorcycletech.info/clutch.htm

He says the replacement piston is part 23-13-1-464-167 which likely your bike already has.

Question...where's the bearing in this setup? Is it built into the piston?

https://bmwmotorcycletech.info/clutch.htm

He says the replacement piston is part 23-13-1-464-167 which likely your bike already has.

Question...where's the bearing in this setup? Is it built into the piston?

gtrider

52184

Thanks for your help on this.

I removed the parts and and the piston was well-lubricated and slid out easily. The boot and other parts seem to be in good shape.

Should I replace the piston? Or something else?

Best regards,

Paul

The throwout bearing may not stick until it and the transmission case are warmed up. And that is a $90 part, so before buying any parts I’d suggest going to https://bmwmotorcycletech.info/transmission.htm and scroll down to the section on throwout bearings. That may give you some checks and measurements that will help in determining if you need a new part.

Best,

DeVern

There was a period of time when that piston was prone to swelling due to heat and then jamming in the bore of the transmission. Don't know which period that was though! Snowbum mentions the "sticky not piston" on this page:

https://bmwmotorcycletech.info/clutch.htm

He says the replacement piston is part 23-13-1-464-167 which likely your bike already has.

Question...where's the bearing in this setup? Is it built into the piston?

Apparently the bearing is integral with the piston. My piston looks exactly like the one pictured on the Max BMW online parts catalog for the above part number.

gtrider

52184

I think it’s time to measure the OD of your piston in a couple of places along its length, and get a handle on the size and checking for any ovality. If it is close to the upper limit mentioned by Snowbum then sand it as he describes, clean everything thoroughly, assemble with a light grease, adjust the clutch using Snowbum’s procedure and a 201mm length of coat hangar wore, and go for a test ride. Be sure to grease the pivot pin and bushing so there’s no binding of the actuating arm.

Best,

DeVern

Best,

DeVern

Update 2

The existing piston is 28.95mm vs. the limit published in the article of 28.7. I know the suggestion is to sand it down but I was able to get a new one locally so I replaced it. The new piston measured 28.65.

I reassembled everthing but I haven't adjusted it yet. I need to read the instructions again, i'm not clear on where to measure the 201mm length.

Thanks,

Paul

I think it’s time to measure the OD of your piston in a couple of places along its length, and get a handle on the size and checking for any ovality. If it is close to the upper limit mentioned by Snowbum then sand it as he describes, clean everything thoroughly, assemble with a light grease, adjust the clutch using Snowbum’s procedure and a 201mm length of coat hangar wore, and go for a test ride. Be sure to grease the pivot pin and bushing so there’s no binding of the actuating arm.

Best,

DeVern

The existing piston is 28.95mm vs. the limit published in the article of 28.7. I know the suggestion is to sand it down but I was able to get a new one locally so I replaced it. The new piston measured 28.65.

I reassembled everthing but I haven't adjusted it yet. I need to read the instructions again, i'm not clear on where to measure the 201mm length.

Thanks,

Paul

gtrider

52184

The existing piston is 28.95mm vs. the limit published in the article of 28.7. I know the suggestion is to sand it down but I was able to get a new one locally so I replaced it. The new piston measured 28.65.

I reassembled everthing but I haven't adjusted it yet. I need to read the instructions again, i'm not clear on where to measure the 201mm length.

Thanks,

Paul

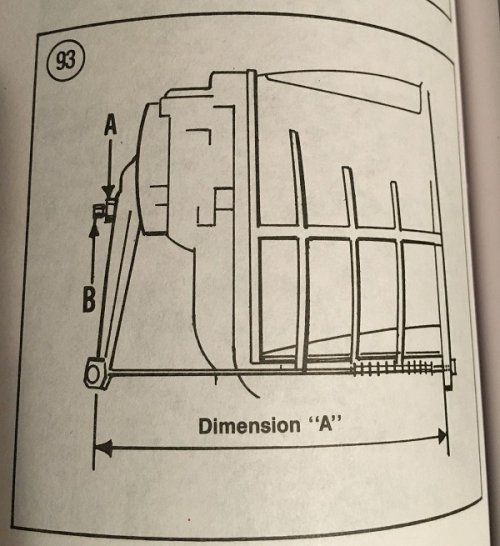

Thanks for the numerical data--that makes the sizing issue clear. On the free play adjustment, the diagram below from the Clymer manual might help:

"A" is the locknut, "B" is the adjusting screw, and dimension "A" should be 201-203mm from the rear face of the boss that holds the clutch cable to the front of the barrel at the actuating arm.

HTH,

DeVern

stevenrankin

Active member

Metal to nylon

Yep, BMW saved some money, and passed the savings onto us customers, LOL, NOT!

I have been reading this from the sidelines and to be honest have never encountered this problem of the piston swelling or sticking. Pictures of the offending parts bring to my question what was BMW thinking when they redesigned a long time working design for the new system?

Nylon replacing metal? In some cases NEVER a good idea for the user, great idea for the company. Cheaper to mold rather than machine, cheaper material and it wears out faster meaning more money from replacement parts and repair costs at dealerships. a win for BMW, a loss for us who buy them.

Design them to be built cheap, and assembled fast then charge the highest price for the BMW name. Yugo quality at BMW price, well maybe not that bad but bad enough, lucky us who buy them and repair them rather than ride them three years and trade them in.

Oh by the way, it is raining this morning and I am grumpy hence the dig at BMW. Praise to those who have been answering this post and providing answers or solutions. St.

Yep, BMW saved some money, and passed the savings onto us customers, LOL, NOT!

I have been reading this from the sidelines and to be honest have never encountered this problem of the piston swelling or sticking. Pictures of the offending parts bring to my question what was BMW thinking when they redesigned a long time working design for the new system?

Nylon replacing metal? In some cases NEVER a good idea for the user, great idea for the company. Cheaper to mold rather than machine, cheaper material and it wears out faster meaning more money from replacement parts and repair costs at dealerships. a win for BMW, a loss for us who buy them.

Design them to be built cheap, and assembled fast then charge the highest price for the BMW name. Yugo quality at BMW price, well maybe not that bad but bad enough, lucky us who buy them and repair them rather than ride them three years and trade them in.

Oh by the way, it is raining this morning and I am grumpy hence the dig at BMW. Praise to those who have been answering this post and providing answers or solutions. St.

https://www.youtube.com/watch?v=Wu2ug--bFPI

Rankin- why don't you knock it off with the negative ways..

Nick

1978 R-80

Rankin- why don't you knock it off with the negative ways..

Nick

1978 R-80

stevenrankin

Active member

None

Rankin- why don't you knock it off with the negative ways..

So, am I to change my ways and sing the everlasting praises of BMW?

Sorry, BMW marketing and engineering need both positive and negative feedback. I will admit, I use this forum to give negative feedback as I have found going through BMW channels over the years concerning problems due to their design plans fall on deaf ears 90% of the time.

I cannot condone making changes in design to something such as going from a well thought out robust design to a "cost saving" design that does not work then bites the owner and mechanics later down the road.

I have not insulted or abused any of the members of this forum, at least I have not been informed by the fine moderators I have done such. When I do, I will change my attitude and if so apologize.

As to my attitude toward BMW, I call a spade a spade, I have made many comments in other posts how it is I lost my respect and love for BMW many years ago. I stay active in this forum because it regards to the best bikes BMW ever made, the airheads. It also contains a lot of people such as myself who do not want to be enslaved or beholden to BMW's dealerships in order to keep their bikes running and repaired. In many cases such as I have encountered personally, current BMW dealerships may not even work on our old bikes. Hence the thankful opening of airhead shops or people who do still admire or enjoy the airheads.

I will gladly sing the praises of such shops and people because of them, I can keep enjoying the two BMW bikes I love. Last time I checked, I have a free right to express my opinions negative or positive. So, no, I will not knock off the negative when it is appropriate. St.

Rankin- why don't you knock it off with the negative ways..

So, am I to change my ways and sing the everlasting praises of BMW?

Sorry, BMW marketing and engineering need both positive and negative feedback. I will admit, I use this forum to give negative feedback as I have found going through BMW channels over the years concerning problems due to their design plans fall on deaf ears 90% of the time.

I cannot condone making changes in design to something such as going from a well thought out robust design to a "cost saving" design that does not work then bites the owner and mechanics later down the road.

I have not insulted or abused any of the members of this forum, at least I have not been informed by the fine moderators I have done such. When I do, I will change my attitude and if so apologize.

As to my attitude toward BMW, I call a spade a spade, I have made many comments in other posts how it is I lost my respect and love for BMW many years ago. I stay active in this forum because it regards to the best bikes BMW ever made, the airheads. It also contains a lot of people such as myself who do not want to be enslaved or beholden to BMW's dealerships in order to keep their bikes running and repaired. In many cases such as I have encountered personally, current BMW dealerships may not even work on our old bikes. Hence the thankful opening of airhead shops or people who do still admire or enjoy the airheads.

I will gladly sing the praises of such shops and people because of them, I can keep enjoying the two BMW bikes I love. Last time I checked, I have a free right to express my opinions negative or positive. So, no, I will not knock off the negative when it is appropriate. St.

https://www.youtube.com/watch?v=Wu2ug--bFPI

Rankin- why don't you knock it off with the negative ways..

Nick

1978 R-80

You are correct Nick!

https://www.youtube.com/watch?v=Wu2ug--bFPI

Rankin- why don't you knock it off with the negative ways..

Nick

1978 R-80

I guess what Nick is saying is that there are other ways to get your point across. One of the other parts of this MOA forum is CAMPFIRE. In Campfire you can elaborate, pontificate, or in general, make your opinions known.

I think that most people come to Airheads to get some help. Not to chat.

But that's just my opinion so I'll just shut up now! No offense intended.

Problem solved!

I adjusted it as shown in the diagram. Thanks for providing it, my factory shop manual doesn't include that information. I have taken a few test rides and the clutch is working perfectly now, no more instances of sticking. Problem solved.

I really appreciate the assistance all of you have given. Your help was spot on - thank you!!!

Best,

Paul

Thanks for the numerical data--that makes the sizing issue clear. On the free play adjustment, the diagram below from the Clymer manual might help:

View attachment 83322

"A" is the locknut, "B" is the adjusting screw, and dimension "A" should be 201-203mm from the rear face of the boss that holds the clutch cable to the front of the barrel at the actuating arm.

HTH,

DeVern

I adjusted it as shown in the diagram. Thanks for providing it, my factory shop manual doesn't include that information. I have taken a few test rides and the clutch is working perfectly now, no more instances of sticking. Problem solved.

I really appreciate the assistance all of you have given. Your help was spot on - thank you!!!

Best,

Paul

I adjusted it as shown in the diagram. Thanks for providing it, my factory shop manual doesn't include that information. I have taken a few test rides and the clutch is working perfectly now, no more instances of sticking. Problem solved.

I really appreciate the assistance all of you have given. Your help was spot on - thank you!!!

Best,

Paul

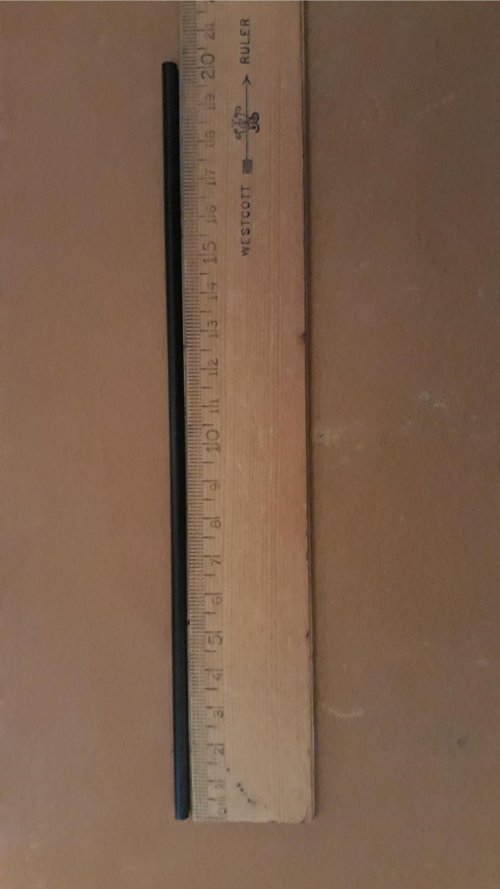

Also, I discovered this coffee straw/stir-stick from a local espresso stand is exactly 202mm long... coincidence?

Similar threads

- Replies

- 7

- Views

- 1K