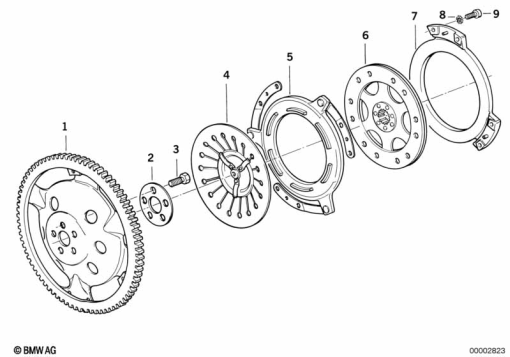

Happy New Year everybody. I am in the process of changing out my trans and clutch, and going back together I'm running into something that's got me stumped. I bought a new (used) transmission due to snapping off the upper right side mounting point, and while I was in there I had the clutch assembly rebuilt (Housing and pressure plate resurfaced and friction disc re-lined). When I bolted the new trans back up I noticed the clutch lever is super sloppy (about half it's travel before it even starts to move the lever on the trans, and won't pull enough to disengage the clutch. At first I thought something must be different between the old and new, but I measured the position of the trans lever, compared the clutch rods and even bolted the old trans back on and the issue persists. Ok, then I must have the clutch assembled wrong but geez, there's not much to it and I don't know how you would get it together incorrectly, I just took it apart again and everything seems to be where it should. I did replace the diaphragm spring plate also, but don't see any difference between old and new either.

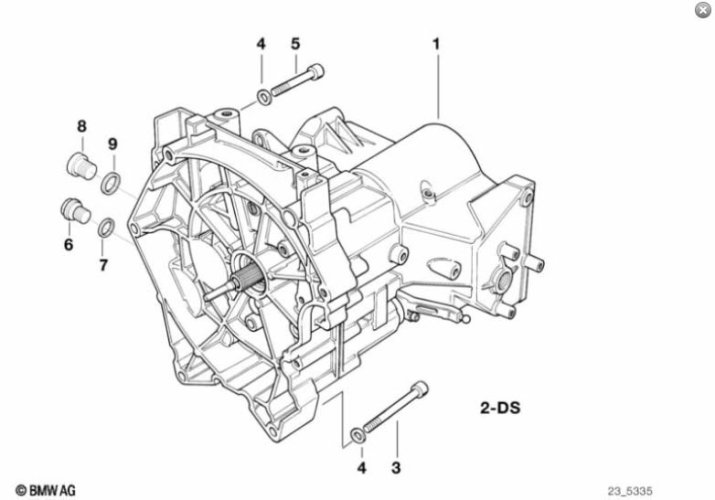

With the trans off I was comparing the position of the clutch rod when inserted in the transmission, and one thing I noticed is that there is some spring tension pushing against the rod until it bottoms out against the clutch lever. With the trans mounted it feels like the rod is not getting pushed far enough into the transmission to contact the lever, hence the excessive slop. Has to be something dumb I'm missing, hoping that someone can enlighten me. Thanks!

With the trans off I was comparing the position of the clutch rod when inserted in the transmission, and one thing I noticed is that there is some spring tension pushing against the rod until it bottoms out against the clutch lever. With the trans mounted it feels like the rod is not getting pushed far enough into the transmission to contact the lever, hence the excessive slop. Has to be something dumb I'm missing, hoping that someone can enlighten me. Thanks!