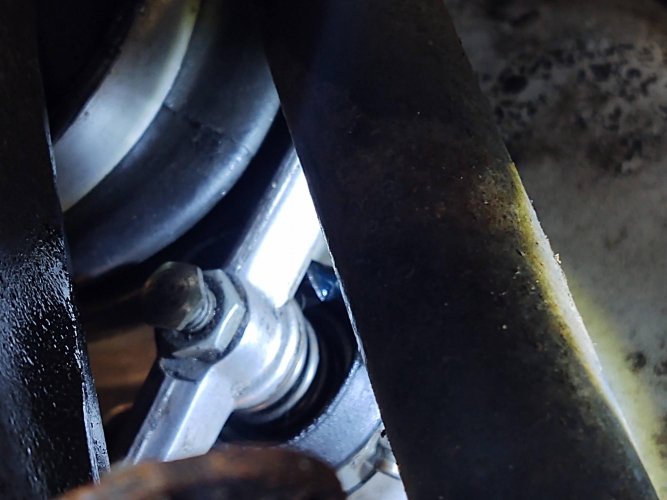

My new bike has already bit me. Two stripped oil pan bolts and a stripped oil filter housing bolt. I don't see a way to do this without pulling the motor.

Do you?

Remind me on the major steps

- disconnect wiring, cables, exhaust

- drive shaft bolts

- I can't recall do I need to pull the final drive,etc.

Do you?

Remind me on the major steps

- disconnect wiring, cables, exhaust

- drive shaft bolts

- I can't recall do I need to pull the final drive,etc.